A food processing plant required precise flow measurement of its main compressed air pipeline to enable energy consumption monitoring and process optimization. The pipeline diameter is DN200, with compressed air as the medium, operating pressure around 7 bar, and medium temperature approximately 35–45°C. The client’s key requirements included:

- High accuracy and long-term stable flow measurement;

- Support for Modbus RTU, 4-20mA, and pulse output to enable PLC remote data acquisition;

- Field installation under pressure to minimize production downtime;

- Easy installation and maintenance with reasonable overall cost.

Aplicación:

Accurate measurement of compressed air flow in a DN200 pipeline of a food processing plant.

Requisitos:

Normal pressure, medium to low flow velocity, high accuracy, multi-output support (Modbus RTU, 4–20mA, pulse, Bluetooth).

Solución:

Operating Conditions and Technical Challenges

- Operating Pressure: 7 bar, suitable for standard pitot tube applications;

- Medium: Clean compressed air with slight oil mist and moisture, which can affect some flow meters’ stability;

- Flow Velocity: 10–80 Nm/s, medium to low flow speed range;

- Installation Requirement: Field installation under pressure to reduce downtime impact;

- System Integration: Multiple industrial signal outputs required for PLC and monitoring system compatibility;

- Cost Control: Budget constraints demanded a solution with high cost-effectiveness.

Solución aportada por Metlan

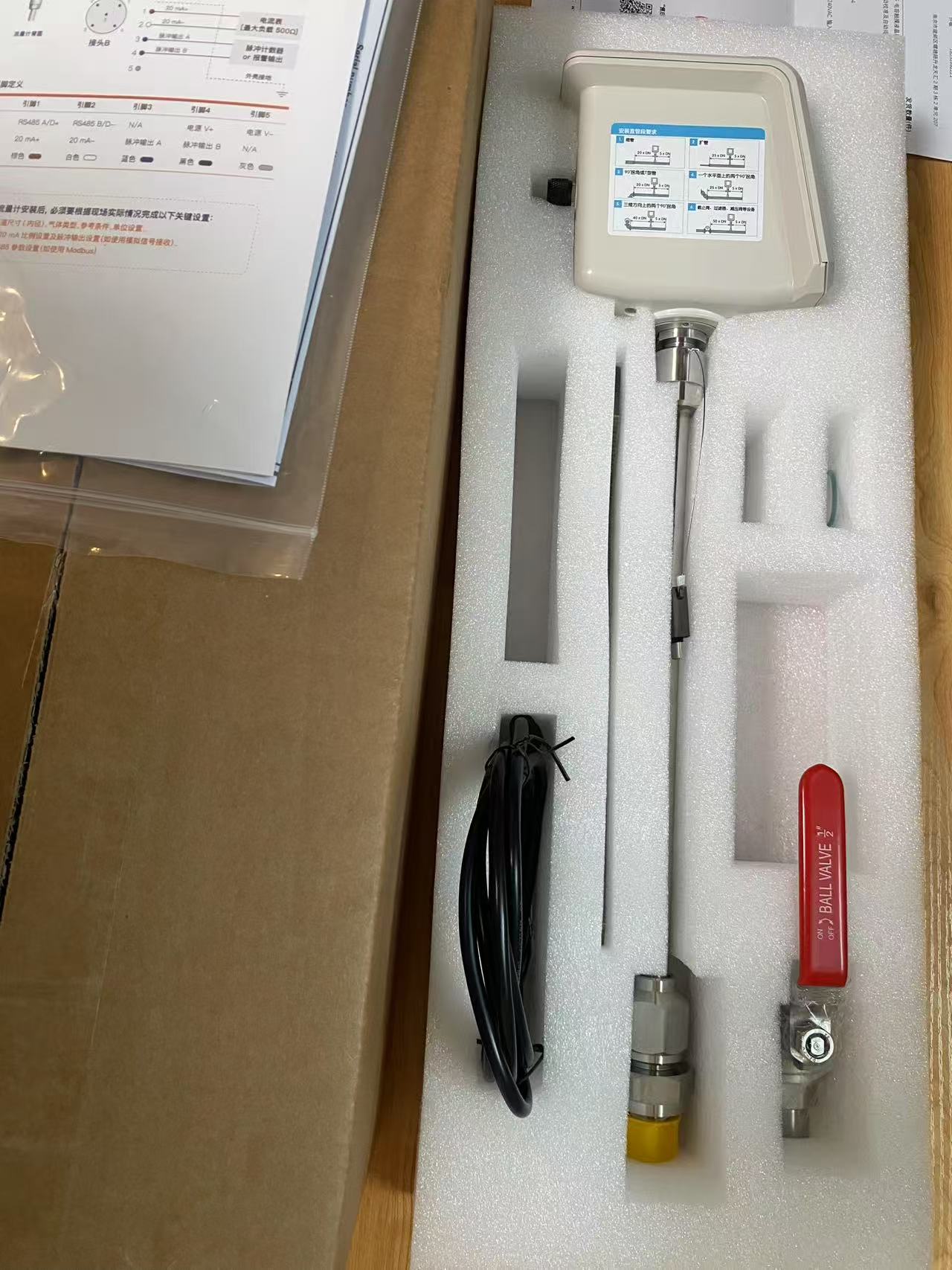

F201A-W Pitot Tube Flow Meter

- Installation: Insertion type, 250 mm probe length

- Measuring Diameter: DN20–DN250 (DN200 for this project)

- Flow Range: 5–300 Nm/s

- Pressure Rating: 1.6 MPa

- Medium Temperature: -40 to 150°C

- Power Supply: 24VDC

- Output Signals: Modbus RTU, 4-20mA, pulse output, Bluetooth

- Process Connection: G1/2″ (ISO 228-1) ball valve

- Display: 2.8″ IPS LCD with capacitive touch screen

Ventajas

1. Insertion Pitot Tube Design

- Equipped with a standard G1/2″ ball valve connection, supporting hot-tap insertion and removal without production shutdown;

- The 250mm probe is suitable for DN200 pipelines, ensuring the sampling point is in a stable flow field and improving measurement accuracy.

2. Accuracy and Stability

- Measurement accuracy reaches ±1%, meeting the client’s requirements for reliable flow data;

- Insensitive to oil mist and moisture, suitable for gas environments with slight contamination.

3. Multiple Output Interfaces

- Supports Modbus RTU, 4-20mA, pulse output, and Bluetooth debugging, with optional customized Wi-Fi and IOT-4G for easy system integration;

- Touchscreen display enables convenient on-site monitoring and parameter adjustment.

4. Low Maintenance, High Cost-Effectiveness

- Simple structure with no heating elements reduces scaling risk;

- Long maintenance intervals with minimal on-site disassembly;

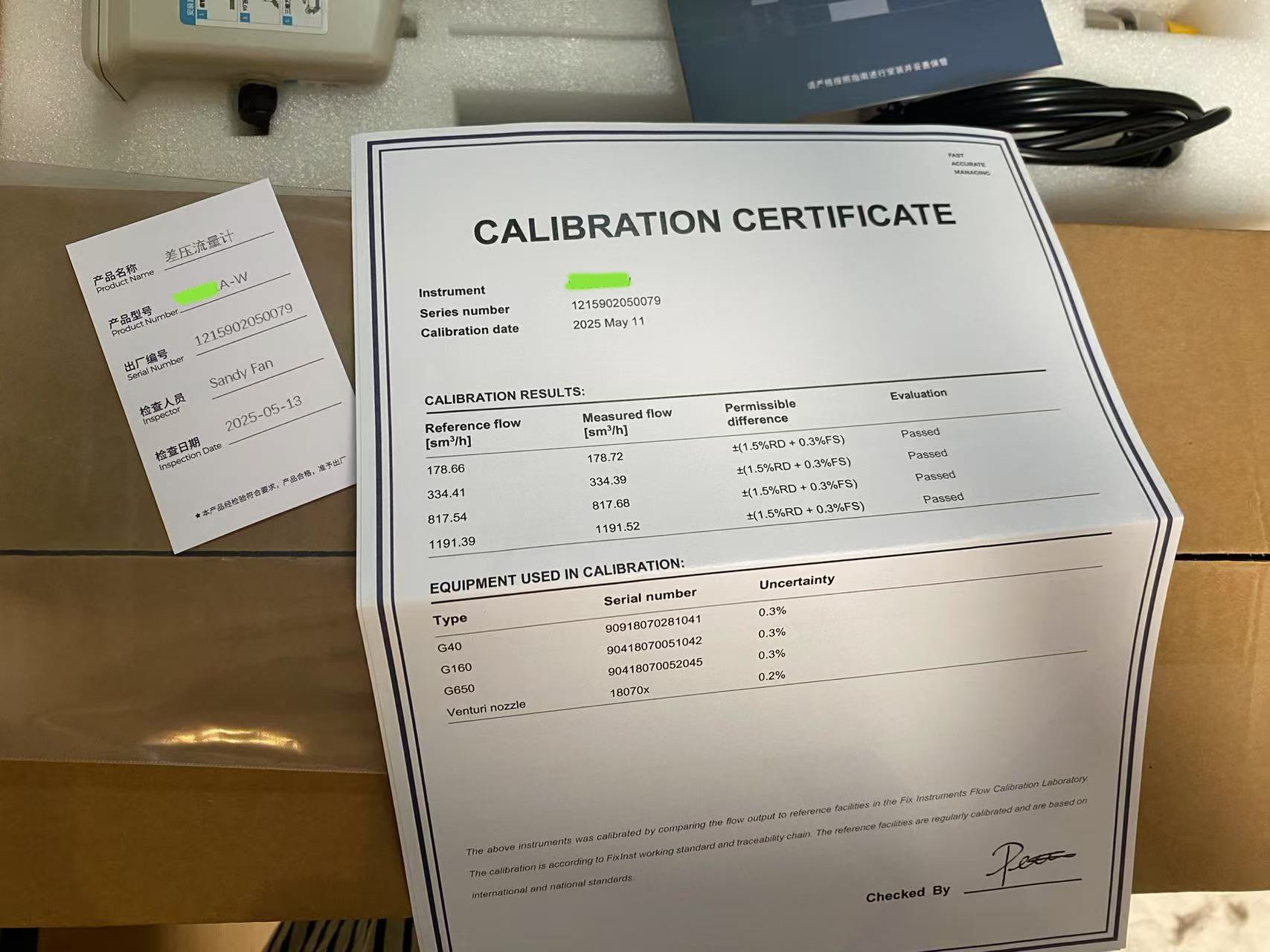

Delivery photo

Each of our flow meters is calibrated and provided with a calibration certificate prior to shipment to ensure product accuracy and long-term stability.

The model number is concealed due to this being a customer-specific OEM order.

Conclusión

This case demonstrates the successful application of the F201A-W Pitot Tube Flow Meter for high-accuracy flow measurement of DN200 compressed air main pipeline. Compared to thermal mass flow meters, the pitot tube solution offers advantages including easy installation, pollution resistance, low maintenance, and excellent cost-performance ratio.

Contact us for application-specific selection and quotation assistance.