In the realm of industrial automation and process control, accurate gas flow measurement is critical for efficiency, safety, and regulatory compliance. Among the advanced technologies available, caudalímetros ultrasónicos de gas han cambiado las reglas del juego y ofrecen soluciones no invasivas y de alta precisión para diversos sectores. Estos medidores aprovechan las ondas sonoras para medir los caudales, lo que los hace ideales para aplicaciones en las que los medidores mecánicos tradicionales se quedan cortos.

Índice

¿Qué es un caudalímetro ultrasónico de gas?

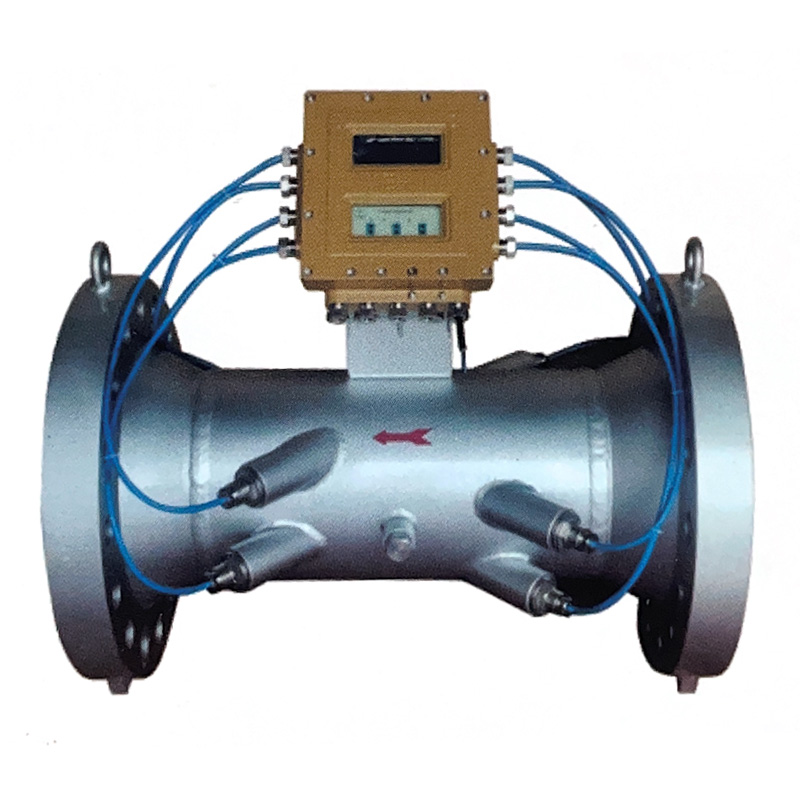

Un caudalímetro ultrasónico de gas es un dispositivo que mide el caudal de gases utilizando ondas ultrasónicas. A diferencia de los caudalímetros mecánicos (por ejemplo, los de turbina o diafragma), los ultrasónicos no tienen piezas móviles, lo que reduce el desgaste y el mantenimiento. Funcionan transmitiendo pulsos ultrasónicos a través de la corriente de gas y analizando cómo afecta el flujo a estos pulsos.

¿Cómo funcionan los caudalímetros ultrasónicos de gas?

Existen dos métodos principales utilizados en la medición de caudal por ultrasonidos:

- Método del tiempo de tránsito (tiempo de vuelo):

- Se montan dos sensores ultrasónicos en lados opuestos de la tubería.

- Los impulsos se envían tanto con y contra el flujo de gas.

- La diferencia de tiempo de tránsito entre las dos direcciones es proporcional a la velocidad del flujo.

- Método del efecto Doppler:

- Las ondas ultrasónicas se reflejan en las partículas o burbujas del gas.

- El desplazamiento de frecuencia (efecto Doppler) provocado por las partículas en movimiento se utiliza para calcular la velocidad del flujo.

Nota: Los medidores de tiempo de tránsito son más comunes para gases limpios, mientras que los medidores Doppler son adecuados para gases con partículas.

Características:

- Alta precisión para gas de hasta ±0,5%

- Sin piezas móviles, sin pérdida de presión, sin obstrucciones en la línea

- Sin lubricación ni mantenimiento periódico

- La medición no se ve afectada por las propiedades del gas

- Amplia relación de reducción

- Capacidad bidireccional

Ventajas de los caudalímetros ultrasónicos de gas

Los caudalímetros ultrasónicos de gas ofrecen ventajas únicas que los convierten en la opción preferida en muchos escenarios:

- Diseño no intrusivo:

- Los modelos con abrazadera pueden instalarse externamente sin cortar las tuberías, lo que minimiza el tiempo de inactividad.

- Los modelos en línea no tienen obstrucciones, lo que garantiza caída de presión cero.

- Alta precisión y repetibilidad:

- Los medidores ultrasónicos modernos alcanzan precisiones de ±1% o mejor, ideal para la transferencia de custodia y facturación.

- Medición bidireccional del caudal:

- Capaz de medir el caudal en ambas direcciones, útil en sistemas de tuberías complejos.

- Amplia relación de reducción:

- Mide con precisión caudales desde velocidades muy bajas hasta altas (por ejemplo, reducción de 100:1).

- Bajo mantenimiento:

- La ausencia de piezas móviles reduce el desgaste y las necesidades de calibración.

- Compatibilidad con tuberías grandes:

- Adecuado para tubos de de 2 cm a varios metros de diámetro.

- Resistencia a condiciones duras:

- Funcionan bien en temperaturas, presiones y entornos corrosivos extremos (con los materiales de sensor adecuados).

Limitaciones de los caudalímetros ultrasónicos de gas

A pesar de sus ventajas, los caudalímetros ultrasónicos tienen limitaciones:

- Sensibilidad a la composición del gas:

- Requiere una composición de gas constante para obtener lecturas precisas.

- El rendimiento disminuye con líquidos arrastrados, partículas pesadas o espuma.

- Dependencia de la temperatura y la presión:

- Las variaciones extremas pueden requerir algoritmos de compensación.

- Mayor coste inicial:

- Más caros que los contadores mecánicos básicos, aunque compensados por el ahorro a largo plazo.

- Eficacia limitada en tuberías pequeñas:

- Los modelos con abrazaderas tienen problemas con las tuberías por debajo de 2 cm de diámetro debido a la atenuación de la señal.

- Requisitos de calibración:

- Puede necesitar recalibración periódica, especialmente para gases mezclados.

¿Qué gases son los más adecuados para los caudalímetros ultrasónicos de gas?

Los medidores ultrasónicos destacan con gases que cumplen criterios específicos:

Gases ideales

- Gases limpios y secos:

- Gas natural, aire comprimido, nitrógeno, oxígeno, argón.

- Un nivel mínimo de partículas o humedad garantiza la fiabilidad de las mediciones del tiempo de tránsito.

- Gases corrosivos:

- Cloro, amoníaco o sulfuro de hidrógeno (con sensores resistentes a la corrosión).

- Gases de gran pureza:

- Se utiliza en la fabricación de semiconductores o productos farmacéuticos.

- Biogás y gases de combustión:

- Metano, CO₂ y otros subproductos de la combustión (método Doppler para partículas).

Gases inadecuados

- Gases muy contaminados: El exceso de polvo, gotas o burbujas interrumpe las señales ultrasónicas.

- Mezclas no homogéneas: La densidad o las propiedades acústicas incoherentes provocan errores.

Aplicaciones e industrias de los caudalímetros ultrasónicos de gas

Los caudalímetros ultrasónicos de gas son herramientas versátiles en todos los sectores que requieren una monitorización precisa del gas:

1. Petróleo y gas

- Transferencia de custodia: Facturación precisa de los gasoductos de gas natural.

- Control de emisiones: Seguimiento de fugas de metano o gas de antorcha.

2. HVAC y gestión de la energía

- Sistemas de aire comprimido: Optimización del uso de la energía en la fabricación.

- Control de la combustión: Regulación de la relación aire/combustible en las calderas.

3. Tratamiento de aguas residuales

- Medición del biogás: Control de la producción de metano en los digestores.

4. Química y petroquímica

- Control del gas de proceso: Garantiza una dosificación precisa de los gases reactivos.

5. Generación de energía

- Análisis de gases de combustión: Medición de las emisiones de CO₂ y SO₂.

6. Industrias farmacéutica y alimentaria

- Suministro de gas estéril: Control del nitrógeno o CO₂ en las líneas de envasado.

7. Control medioambiental

- Pruebas de apilamiento: Cumplimiento de la normativa sobre calidad del aire.

Cómo elegir el caudalímetro ultrasónico de gas adecuado

Seleccionar el mejor medidor implica evaluar:

- Propiedades del gas: Limpieza, humedad y corrosividad.

- Tamaño y material de los tubos: Instalación con abrazaderas frente a instalación en línea.

- Necesidades de precisión: Transferencia de custodia frente a supervisión general.

- Condiciones medioambientales: Certificaciones de temperatura, presión y zonas peligrosas (por ejemplo, ATEX).

- Presupuesto: Equilibrar los costes iniciales con el ahorro a largo plazo.

Los caudalímetros ultrasónicos de gas están revolucionando la medición de gases gracias a su diseño no invasivo, su alta precisión y su adaptabilidad. Aunque puede que no se adapten a todas las aplicaciones (por ejemplo, gases muy contaminados), sus ventajas en entornos limpios y de alta precisión los hacen indispensables para sectores como el del petróleo y el gas, la climatización y la vigilancia medioambiental.