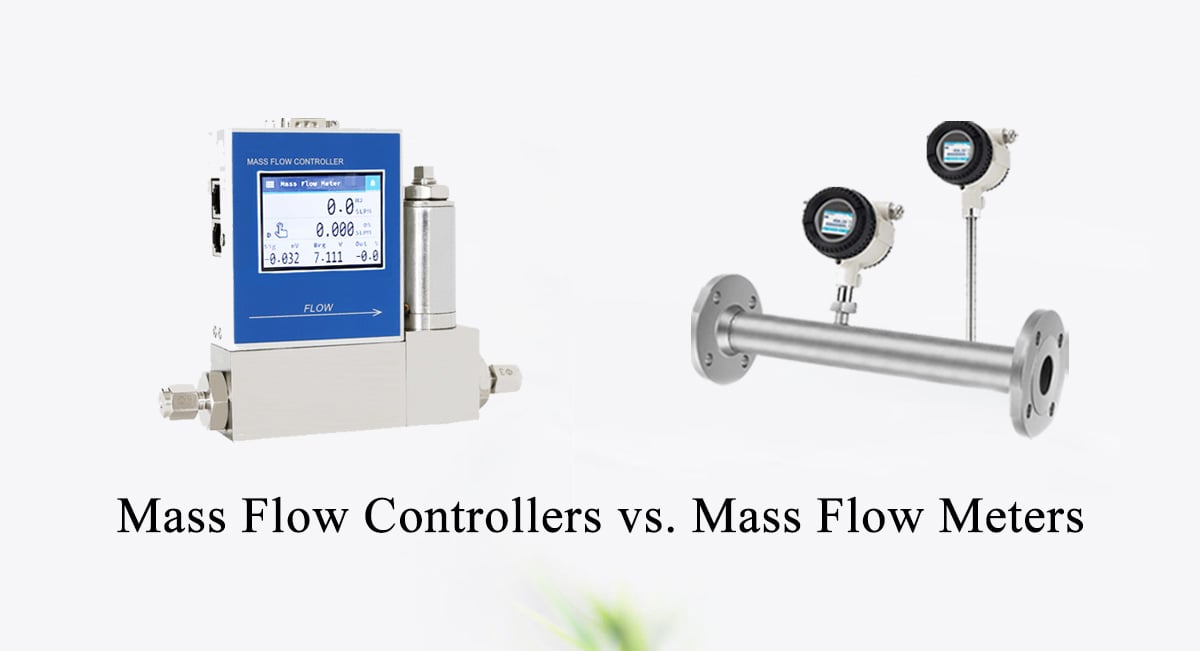

In industries where the precise measurement of gases and liquids is critical, two terms often come up: Mass Flow Controllers (MFCs) y Caudalímetros másicos (MFMs). At first glance, they may appear similar because both are designed to measure flow in terms of mass per unit time. However, there are fundamental differences in their design, purpose, and applications.

Choosing the right instrument for your process depends on whether you need measurement only o measurement with active control. In this article, we will explore what MFCs and MFMs are, how they work, the differences between them, and where each is most useful.

Índice

1. What Is a Mass Flow Controller (MFC)?

A Mass Flow Controller (MFC) is a precision device designed to measure and control the flow of gases or liquids. Unlike simple meters, which only provide measurement data, MFCs actively regulate flow to match a user-defined setpoint.

1.1 How MFCs Work

- Most MFCs use a thermal mass flow sensor. A small portion of the gas is diverted through a capillary tube containing temperature sensors. As the gas flows, it carries heat away, and the change in temperature distribution is proportional to the mass flow rate.

- The MFC compares this measured flow rate to the desired setpoint.

- An integrated control valve automatically adjusts to increase or decrease the flow, maintaining it at the target level.

Some advanced MFCs use Coriolis-based sensors, which measure the force exerted on a vibrating tube by the moving mass of the fluid. This provides even higher accuracy and is ideal for multi-gas or variable composition applications.

1.2 Key Features of MFCs

- Provide both measurement and closed-loop control

- Adecuado para aplicaciones de bajo caudal, often measured in SCCM (standard cubic centimeters per minute) to SLPM (standard liters per minute)

- Offer digital communication protocols such as RS485, Profibus, or EtherCAT for integration into automated systems

- Typically calibrated for a specific gas or liquid, although some multi-gas MFCs exist

Caudalímetro másico Coriolis / Controlador MTL20FE

The MTL20FE series Coriolis mass flow controller/flowmeter is a high-precision instrument that utilizes advanced Coriolis technology to deliver exceptionally accurate fluid measurements unaffected by fluid characteristics, making it ideal for measuring extremely small flow rates with unparalleled reliability. Through continuous technological innovations, this series not only provides direct mass flow measurement but also simultaneously measures…

Medidor / controlador de caudal másico de presión diferencial MTL20FC

Basado en el principio de presión diferencial, la serie de medidores / controladores de caudal másico MTL20FC puede mostrar y emitir simultáneamente caudal instantáneo, caudal acumulado, presión, temperatura, etc. Cuando se requieren funciones de control, también se pueden instalar válvulas electromagnéticas de control proporcional y funciones de ajuste PID incorporadas.

Medidor / Controlador de caudal másico de gas térmico (MTL20FD)

MTL20FD is a high precision series of mass flow meters / controllers, with accuracy up to ± 0.5% of full scale based on thermal principle. It can be used for various experiments in laboratories and complex industrial environments. In order to adapt tocomplex industrial environments, we also have somemodels that support IP67 dust and waterproof…

Digital Liquid Mass Flow Meter / Controller MTL10L

The MTL10L Series digital liquid flow controllers and flow meters deliver fast and precise measurement of both volumetric and mass flow rates for process liquids. Each unit features a custom-engineered high-speed proportional control valve that ensures accurate and stable flow regulation under varying operating conditions. Multi-variable measurement and a 50:1 adjustable range allow a single…

2. What Is a Mass Flow Meter (MFM)?

A Mass Flow Meter (MFM) is a device designed to measure the mass flow rate of a gas or liquid but does not control it. Its function is purely diagnostic and monitoring rather than regulatory.

2.1 How MFMs Work

MFMs can be based on several different measurement technologies:

- Caudalímetros Coriolis: Measure the deflection of a vibrating tube as fluid passes through, providing a direct mass flow reading.

- Caudalímetros másicos térmicos: Use the same heat transfer principle as MFCs but without the integrated control valve.

- Differential Pressure (DP) Mass Flow Meters: Infer mass flow from measured pressure drop across a known restriction.

2.2 Key Features of MFMs

- Provide accurate mass flow measurement only

- Cover a much wider flow range compared to MFCs

- Often used in large-scale industrial applications

- May be designed for harsh environments with high pressure and temperature

3. What’s the Differences between Mass Flow Controllers and Mass Flow Meters?

While both instruments measure mass flow, their differences are significant.

| Característica | Mass Flow Controller (MFC) | Mass Flow Meter (MFM) |

|---|---|---|

| Función principal | Measurement and active control | Measurement only |

| Válvula de control | Yes, integrated | No |

| Salida | Flow data + regulated flow stream | Flow data only |

| Aplicaciones | Low-flow, high-precision dosing | Monitoring across small and large flow ranges |

| Coste | Higher due to control capability | Lower compared to MFCs |

| Complexity | More complex, requires calibration | Simpler design, easier maintenance |

| Precisión | High accuracy at low flow | High accuracy across wider flow ranges |

Resumiendo:

- MFCs are best when you need active control of flow.

- MFMs are best when you only need to monitor flow.

4. Applications of Mass Flow Controllers (MFCs)

MFCs are widely used in precision industries where flow stability is critical:

- Semiconductor manufacturing: For delivering controlled amounts of process gases during wafer fabrication.

- Laboratories and R&D: For precise dosing of gases in experiments.

- Biotechnology & pharmaceuticals: To maintain sterile and consistent gas environments in bioreactors.

- Fuel cells: For regulating hydrogen and oxygen supply.

- Gas mixing systems: To control multiple gas inputs at defined ratios.

In these cases, an uncontrolled variation in flow could compromise safety, product quality, or experimental accuracy.

5. Applications of Mass Flow Meters (MFMs)

MFMs are used in industrial-scale applications where monitoring is essential, but active control is not required:

- Oil & Gas: Measuring natural gas, LNG, and refinery products.

- Generación de energía: Monitoring combustion gases, steam, and fuel feed.

- Chemical Processing: Measuring process gases and liquids for efficiency and compliance.

- Food & Beverage: Monitoring CO₂ in carbonated beverages.

- Environmental monitoring: Measuring emissions and exhaust gases for regulatory compliance.

These industries value MFMs because they offer high reliability over large flow ranges, even in demanding environments.

6. How to Choose Between an MFC and an MFM

When deciding whether to use an MFC or an MFM, consider the following:

- Do you need control or just measurement?

- Choose an MFC if you need to set and maintain a specific flow rate.

- Choose an MFM if you only need to monitor flow.

- What is your flow range?

- MFCs are ideal for low flow aplicaciones.

- MFMs can handle both low and very high flow rates.

- What’s your budget?

- MFCs are more expensive but save time and improve precision.

- MFMs are cost-effective if control is unnecessary.

- What’s your industry requirement?

- High-tech industries like semiconductors almost always require MFCs.

- Large-scale industries like oil & gas rely on MFMs.

Both Mass Flow Controllers y Caudalímetros másicos are indispensable tools in industrial measurement and process control. While they share a common goal of measuring flow in terms of mass, their roles are distinct:

- MFCs measure and actively regulate flow, making them the choice for low-flow, precision applications.

- MFMs provide accurate flow measurement across a wider range, making them the choice for monitoring in large-scale industrial processes.

Understanding the differences and selecting the right instrument can significantly improve process efficiency, product quality, and overall operational reliability.