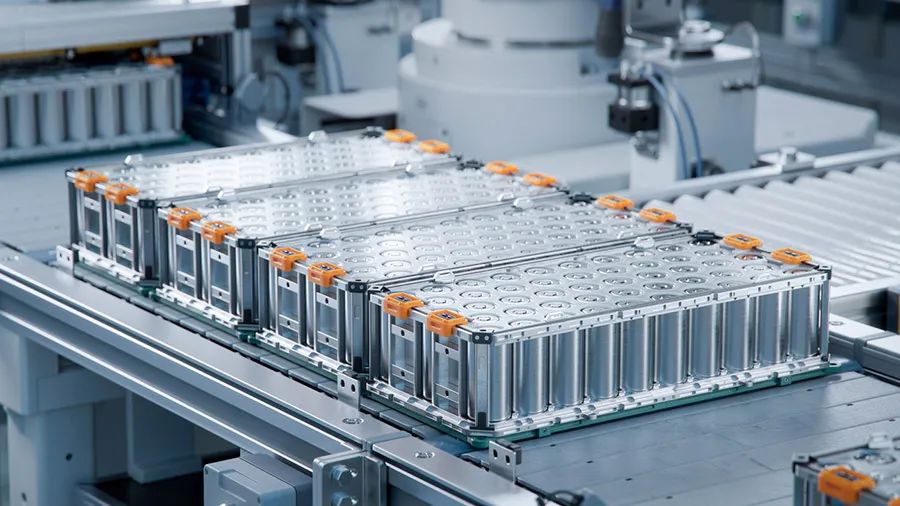

Con el continuo crecimiento del mercado de vehículos de nueva energía, las industrias de la cadena de suministro relacionadas también han experimentado un aumento. Como uno de los componentes más críticos, las baterías de litio suponen 40%-50% del coste. En la producción de baterías de litio, el material del cátodo representa aproximadamente 36% del coste total. Como consecuencia, la demanda de materiales de cátodo ha crecido exponencialmente, y el funcionamiento eficaz de las líneas de producción de materiales de cátodo depende en gran medida de diversos instrumentos de medición de caudal.

Índice

Nueva industria energética

Tomemos como ejemplo el proceso de producción de materiales catódicos precursores ternarios para baterías de litio:

Preparación de soluciones de materias primas a partir del tratamiento de pilas usadas

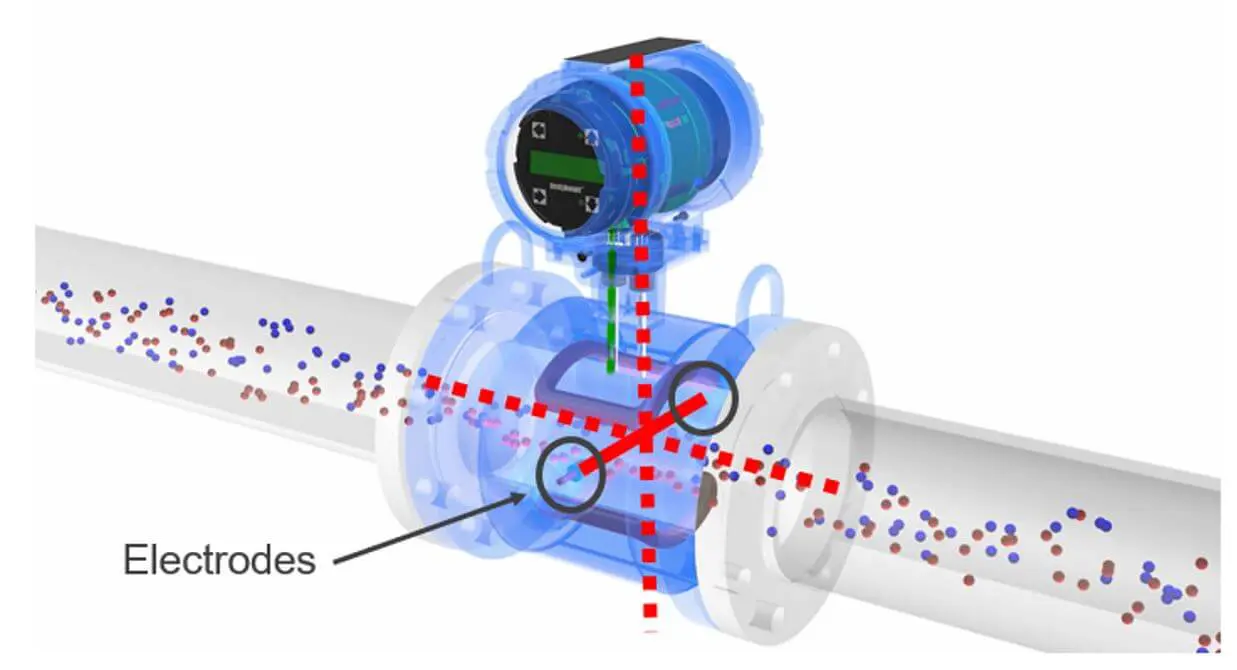

- Taller de lixiviación: Los caudalímetros electromagnéticos se utilizan para medir con precisión el caudal de la solución de sulfato, el ácido sulfúrico concentrado, la alimentación del tanque ácido-base, la descarga del tanque de reacción de lixiviación y el lodo, garantizando la precisión de todo el proceso de reacción y la calidad del producto final.

- Taller de extracción: Los caudalímetros electromagnéticos son necesarios para el control preciso del flujo en el tanque de circulación ácido-base, el tanque de clarificación, el tanque de almacenamiento de extractante y el eluato de agua purificada, con el fin de generar la solución final de materia prima de acuerdo con los requisitos del proceso.

Preparación de la solución de materia prima a partir de cristales de sulfato comprados

- En esta etapa del proceso, los caudalímetros electromagnéticos supervisan la dosificación de materiales en tanques de disolución de metales (dosificación), tanques de almacenamiento de líquido de cobalto, tanques de almacenamiento de disoluciones metálicas, tanques de almacenamiento de agua amoniacal, tanques de almacenamiento de sosa cáustica líquida y tanques intermedios concentrados. Los caudalímetros desempeñan un papel fundamental a la hora de garantizar la exactitud de las proporciones de material, algo esencial para la correcta formulación de las materias primas.

Aplicación:

Caudalímetros en la producción de baterías de litio

Requisitos:

Alta precisión / Resistencia a la corrosión

Resistencia a las interferencias / Fiabilidad

Aplicaciones

En el proceso de producción de materiales catódicos para baterías de litio hierro fosfato, los caudalímetros electromagnéticos desempeñan un papel crucial:

- Medición del caudal de entrada de materias primas

Para garantizar una mezcla y un control precisos de las materias primas, los caudalímetros electromagnéticos miden con exactitud el caudal de diversas materias primas y proporcionan información al sistema de control automático para su ajuste.

- Control del flujo del fluido de reacción

En procesos como la sinterización y la molienda por bolas, los caudalímetros electromagnéticos controlan el caudal de los fluidos de reacción en tiempo real, lo que garantiza una mezcla suficiente de los reactivos y mejora la calidad del producto y la eficacia del proceso.

- Control del vertido de aguas residuales

Los caudalímetros electromagnéticos desempeñan un papel importante en el vertido de aguas residuales, supervisando el volumen de vertido en tiempo real y utilizando sistemas de control automático para racionalizar el vertido de aguas residuales y reducir el impacto ambiental.

Requisitos

A medida que los procesos de producción se vuelven más complejos, la industria de las baterías de litio tiene mayores requisitos para los caudalímetros electromagnéticos, entre los que se incluyen los siguientes:

- Alta precisión: Los caudalímetros electromagnéticos deben ofrecer una gran precisión y estabilidad para asegurar una medición exacta del caudal de líquido de reacción, garantizando así unos procesos de producción eficaces y precisos.

- Resistencia a la corrosión: Dado que en la producción intervienen sustancias muy corrosivas, como ácidos y álcalis, los sensores y las tuberías de los caudalímetros electromagnéticos deben estar fabricados con materiales resistentes a la corrosión para garantizar un funcionamiento estable a largo plazo.

- Resistencia a las interferencias: Debido a la presencia de ruido, interferencias electromagnéticas y otros factores en el entorno de producción, los caudalímetros electromagnéticos deben estar equipados con tecnología antiinterferencias para eliminar el impacto de las perturbaciones externas en la precisión de la medición.

- Fiabilidad: Los caudalímetros electromagnéticos deben ser altamente fiables y duraderos, capaces de funcionar de forma estable durante periodos prolongados en los procesos de producción, garantizando la estabilidad a largo plazo y la alta eficiencia del equipo.

Producto utilizado

Caudalímetro electromagnéticos con bridas (MTF-F-100)

- Gama de diámetros nominales: DN 15 a 3000 (½" a 120″)

- Precisión: Estándar ±0,5 %, Opcional ±0,2 %

- Rango de medición: 0,3 m³/h a 125000 m³/h

- Máx. Presión de proceso: 100 bar (1450,38 psi)

- Temperatura ambiente: -25ºC ~ 60ºC

- Temperatura ambiente: -25ºC ~ 60ºC

- Salidas: 4-20 mA, Frecuencia, Pulso

- Comunicación digital: RS485 (HART y otras bajo pedido)

- Fuente de alimentación: DC 24 V / AC 100 a 240 V

- Conducitvidad eléctrica media: ≥5µS/cm

Beneficios

- Mayor precisión: Los caudalímetros electromagnéticos Metlan tienen una precisión de 0,5%, mientras que los caudalímetros del mercado suelen tener una precisión de entre 3-5%. En función de los requisitos del cliente, podemos alcanzar una precisión de 0,2%. Cada caudalímetro se calibra y se le asigna un número de serie único que corresponde a todos los datos de calibración. El equipo de calibración cumple la norma nacional JJG 164-2000.

- Ahorro de costes: Medición precisa, reducción de errores, mejora de la exactitud de la facturación y evitación de pérdidas de ingresos.

- Personalización: Los caudalímetros se pueden personalizar según las condiciones de trabajo reales y los requisitos medioambientales, como el revestimiento y los electrodos, lo que garantiza que el caudalímetro sea adecuado para entornos específicos y funcione de forma estable a largo plazo.

Más caudalímetros recomendados

Además, Metlan Instruments ofrece instrumentos de medición de caudal más profesionales para la industria de las baterías de litio:

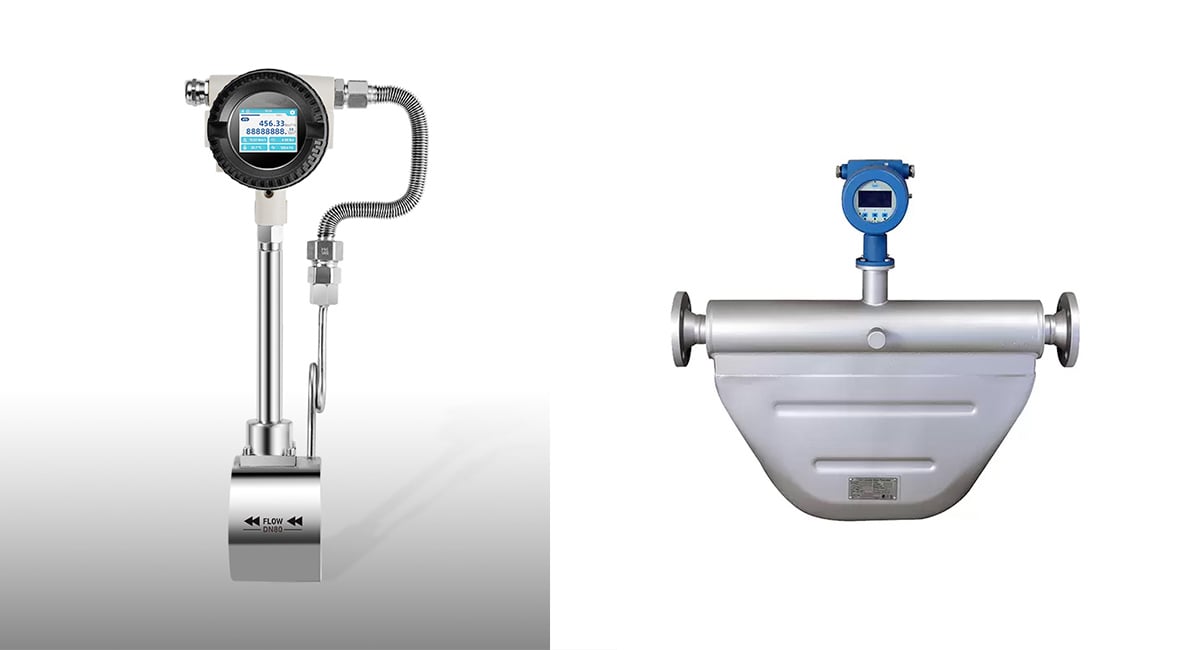

Caudalímetros de vortex

- Ayuda a supervisar los cambios en el flujo de líquido durante la preparación de materiales catódicos, lo que permite controlar parámetros clave como la velocidad de alimentación y la velocidad de reacción, gestionando así el proceso de preparación de materiales y garantizando la estabilidad y consistencia de la calidad del producto.

- Además, el caudalímetro vortex también puede utilizarse para controlar el caudal y la proporción, lo que garantiza un control preciso de los componentes líquidos durante la preparación de los materiales catódicos, mejorando así la eficacia de la producción y la calidad del producto.

Caudalímetros Coriolis

- El caudalímetro másico se utiliza para medir el caudal másico de líquidos, ofreciendo una gran precisión de medición que no se ve afectada por los cambios de densidad o temperatura del medio. Además, puede proporcionar mediciones multiparámetro. En la fase de molienda de la pasta de la línea de producción de material catódico de fosfato de hierro y litio, se suelen emplear caudalímetros másicos para medir el caudal másico de la pasta.

- Estos medidores garantizan un control preciso del caudal másico de la pasta, que es crucial para mantener la consistencia del proceso de molienda. Controlando con precisión el caudal de la pasta, se puede optimizar el proceso de producción, garantizando la uniformidad de las propiedades del material y mejorando la calidad general del producto. La alta precisión de los caudalímetros másicos en este tipo de aplicaciones es vital para conseguir las características de rendimiento deseadas en el material catódico final.

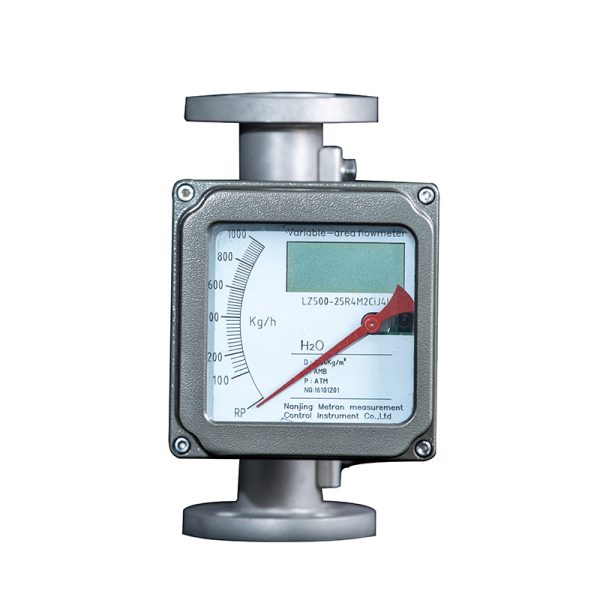

Rotámetros

- El caudalímetro de rotor metálico puede ayudar a supervisar los cambios en el flujo de líquido durante la producción de materiales catódicos, lo que permite un control preciso de parámetros clave como la velocidad de alimentación del material y la velocidad de reacción. Esto garantiza la estabilidad y consistencia de la calidad del producto durante todo el proceso de preparación.

- Además, los caudalímetros de rotor metálico también se utilizan para el control y la dosificación del caudal, lo que garantiza el control preciso de los componentes líquidos durante el proceso de producción de material catódico, mejorando así la eficacia de la producción y la calidad del producto.

Conclusión:

A medida que la industria de las baterías de litio sigue creciendo en respuesta a la creciente demanda de vehículos de nueva energía, la necesidad de una medición precisa y fiable del flujo en la producción de materiales catódicos se hace cada vez más crítica. Instrumentos MetlanLos caudalímetros, con su alta precisión, resistencia a la corrosión y capacidad para gestionar requisitos de procesos complejos, desempeñan un papel clave a la hora de garantizar el funcionamiento eficaz y uniforme de las líneas de producción. Desde la medición precisa de ingredientes hasta la supervisión en tiempo real de fluidos de reacción y vertidos de aguas residuales, estos instrumentos son indispensables para controlar parámetros críticos que repercuten directamente en la calidad del producto, la eficacia del proceso y la sostenibilidad medioambiental. A medida que evolucione la industria, seguirá aumentando la demanda de tecnologías avanzadas de medición de caudal, que requieren equipos que cumplan las normas más estrictas de precisión, durabilidad y resistencia a las interferencias.

Deja un comentario