Water Flow Meters

Magnetic Flow Meter for Water and Wastewater (MTF-W)

Accuracy

Standard: ±0.5 %, Optional: ±0.2 %

Measuring Range

1 m³/h to 125000 m³/h

Medium Temperature Range

PU:0 to 140°F (-18 to 60°C)

Neoprene:-13°F to 176°F (-25°C to +80°C)

PTFE:-13 to 300°F (-25 to 150°C)

Max. Process Pressure

100 bar (1450.38 psi)

Remote Electromagnetic Flow Meter (MTF-F-200)

Accuracy

Standard: ±0.5 %, Optional: ±0.2 %

Measuring Range

0.3 m³/h to 125000 m³/h

Medium Temperature Range

PU:0 to 140°F (-18 to 60°C)

Neoprene:-13°F to 176°F (-25°C to +80°C)

IR:-13°F to 176°F (-25°C to +80°C)

FEP:-13 to 300°F (-25 to 150°C)

PTFE:-13 to 300°F (-25 to 150°C)

ETFE:-40 to 356°F (-40 to 180°C)

PFA:-40 to 356°F (-40 to 180°C)

Max. Process Pressure

100 bar (1450.38 psi)

Flanged Electromagnetic Flow Meter (MTF-F-100)

Accuracy

Standard: ±0.5 %, Optional: ±0.2 %

Measuring Range

0.3 m³/h to 125000 m³/h

Medium Temperature Range

PU:0 to 140°F (-18 to 60°C)

Neoprene:-13°F to 176°F (-25°C to +80°C)

IR:-13°F to 176°F (-25°C to +80°C)

FEP:-13 to 300°F (-25 to 150°C)

PTFE:-13 to 300°F (-25 to 150°C)

ETFE:-40 to 356°F (-40 to 180°C)

PFA:-40 to 356°F (-40 to 180°C)

Max. Process Pressure

100 bar (1450.38 psi)

Insertion Magnetic Flow Meters (MTF-I)

Accuracy

Standard: ±1.5 %

Measuring Range

16 m³/h to 125000 m³/h

Medium Temperature Range

< 80°C (176°F)

Max. Process Pressure

25 bar (362.6 psi)

Steam Vortex Flow Meter Anti-vibration (LUGBMT-VS)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Steam/Gas: 3.5 to 20347.2 m³/h

Medium Temperature Range

Standard: –40 to +160 °C

High/low temperature (option): –180 to +350 °C

Max. Process Pressure

63 bar (913.74 psi)

Vortex Flow Meters (LUGBMT-100)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Liquid: 0.8 to 3500 m³/h

Steam, gas: 5 to 18000 m³/h

Medium Temperature Range

Standard: –40 to +260 °C (–40 to +480 °F)

High/low temperature (option): –200 to +400 °C (–328 to +750 °F)

Max. Process Pressure

100 bar (1450.38 psi)

Vortex Flow Meters with Temperature and Pressure Compensation (LUGBMT-C)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Liquid: 0.8 to 3500 m³/h

Steam, gas: 5 to 18000 m³/h

Medium Temperature Range

Standard: –40 to +260 °C (–40 to +480 °F)

High/low temperature (option): –200 to +350 °C (–328 to +660 °F)

Max. Process Pressure

100 bar (1450.38 psi)

Liquid Turbine Flow Meter (LWGYMT-100)

Accuracy

Standard: ±1 %, Optional: ±0.5 %

Measuring Range

0.04 to 800 m³/h

Medium Temperature Range

standard: -20 TO 120 °C (–4 to +248 °F)

Max. Process Pressure

250 bar (3625.95 psi)

Battery Powered Magnetic Flowmeter (MTF-B)

Accuracy

Standard: ±0.5 %

Measuring Range

0.15 m³/h to 9000 m³/h

Medium Temperature Range

PU:0 to 140°F (-18 to 60°C)

Neoprene:-13°F to 176°F (-25°C to +80°C)

PTFE:-13 to 300°F (-25 to 150°C)

Max. Process Pressure

100 bar (1450.38 psi)

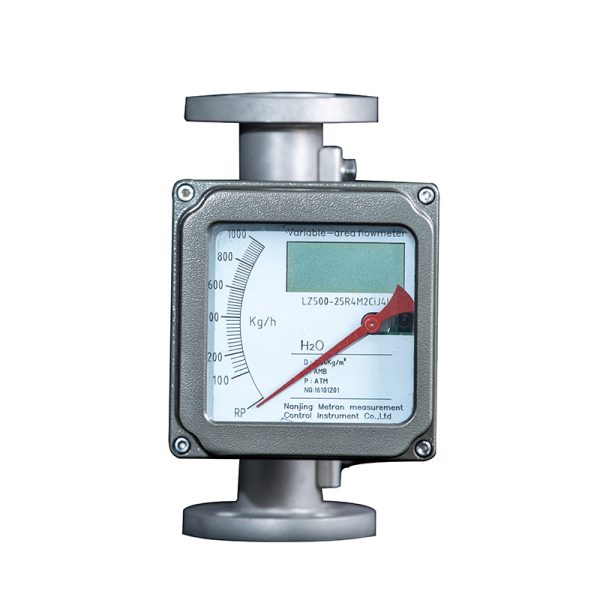

Rotameter Metal Variable Area Flow Meters (MTLZ-M)

Accuracy

Standard: ±2.5 %, Optional: ±1.5 %

Measuring Range

Liquid:1.0~150000l/h

Gas:0.05~3000m³/h

Medium Temperature Range

standard: -80 TO 350 °C (–112 to +662 °F)

Max. Process Pressure

DN15-50:200 bar (2900.76 psi)

DN80-100: 100 bar (1450.38 psi)

Factors to Consider When Choosing a Water Flow Meter

-

Water Quality

Water quality plays a significant role in determining the most suitable flow meter. For example, clean water allows for a broader range of meters, including mechanical types. However, for dirty, corrosive, or wastewater, more specialized meters like electromagnetic or ultrasonic meters are preferable, as they can handle impurities and chemical properties without clogging or degrading. -

Flow Rate and Range

The range of flow rates you need to measure also impacts your meter choice. Some meters perform well at low flow rates, while others are more suited for high-volume flows. Understanding the required flow range helps prevent errors and ensures consistent accuracy. -

Installation Environment

Some flow meters are highly sensitive to installation conditions, including pipe orientation, temperature, and pressure. It’s crucial to determine whether your system can accommodate a certain type of meter without significant modifications. For instance, ultrasonic meters can be installed non-intrusively, while mechanical meters need to be placed inside the pipe. -

Accuracy Requirements

If precision is critical—such as in billing systems, industrial processes, or water treatment—choosing a highly accurate meter is essential. Certain flow meters, like Coriolis and electromagnetic meters, offer excellent accuracy, making them ideal for applications where precision matters. -

Maintenance and Durability

Some flow meters have moving parts that are prone to wear, requiring regular maintenance. For long-term reliability, non-mechanical meters like ultrasonic or magnetic flow meters, which have no moving parts, are preferred. Assess the maintenance needs and the durability of the meter, especially if it’s being used in harsh or remote environments. -

Budget

Cost is always a consideration. While high-precision flow meters may offer better performance, they can come with a higher price tag. It’s important to weigh the cost against the benefits you’ll get from the meter in terms of accuracy, lifespan, and reliability.

Recommended Water Flow Meter Types and Reasons

| Types | Best for | Pros. | Cons. |

|---|---|---|---|

| Electromagnetic Water Flow Meters | Clean and dirty water, wastewater, and applications where accuracy is key. |

|

|

| Turbine Water Flow Meters | Clean water applications, low-budget systems, and steady flow rates |

|

|

| Vortex Water Flow Meters | Industrial applications with fluctuating flow rates and moderate impurities |

|

|

| Differential Pressure (DP) Water Flow Meters | High-pressure systems, large water distribution networks, and water treatment plants. |

|

|

Choosing the Right Flow Meter for Your Application

-

For potable water systems

Consider ultrasonic or turbine flow meters. Ultrasonic is more expensive but offers non-intrusive installation, while turbine meters are more budget-friendly for clean water applications. -

For wastewater or dirty water

Electromagnetic (magmeters) or vortex meters are best. Magmeters are ideal for dirty or corrosive water, while vortex meters can handle fluids with moderate impurities. -

For precise billing

Positive displacement flow meters provide the most accuracy at low flow rates, making them perfect for residential or commercial billing applications. -

For industrial water measurement

Vortex or DP flow meters work well in industrial settings where water flow can be variable, and durability is key. -

For large-scale municipal systems

Electromagnetic or differential pressure flow meters are suited for large pipes and high flow rates typical in municipal water distribution.