Oil Flow Meters

Oil flow meters are designed to handle different oil types, ranging from low-viscosity oils like diesel or gasoline to high-viscosity oils like heavy fuel oil or lubricants. The accurate measurement of oil flow is crucial in industries such as oil and gas, energy, chemical processing, and automotive sectors, where flow data is essential for process control, inventory management, billing, and regulatory compliance. We recommend the following oil flow meters according to different viscosity range, flow range, accuracy, maintenance, and upfront cost.

| Factor | PD Meter | Coriolis Meter | Turbine Meter |

|---|---|---|---|

| Viscosity Range | All | All | Low |

| Flow Range | Low to moderate | Low to moderate | High |

| Accuracy | ±0.1–0.5% | ±0.1–0.5% | ±0.5–1% |

| Maintenance | Moderate | Low | Low (clean fluids) |

| Upfront Cost | Medium | High | Low |

Positive Displacement (PD) Flow Meters

Bi-rotor Positive Displacement Flow Meter (MT-ABR)

- High accuracy up to ±0.1 %

- Strong applicability to viscosity changes.

- Good anti-interference performance and long service life.

Accuracy

Standard: ±0.5 %, Optional: ±0.2 %; ±0.1 %

Measuring Range

0.3 to 1800 m³/h

Medium Temperature Range

Standard: (-20~+100) ℃, Optional: (-20~+250) ℃

Max. Process Pressure

110 bar (1595 psi)

Low Flow Positive Displacement Gear Flow Meter MT-GF

- Designed for low flow liquids from 0.6 L/H.

- 150:1 wide turndown ratio

- Capable of measuring highly corrosive medium.

Accuracy

±0.5 %

Measuring Range

0.6 to 2000 l/h

Medium Temperature Range

Standard: (-40~+80) ℃, Optional: (-40~+200) ℃

Max. Process Pressure

Standard: 100 bar, Optional: 400 bar

M Series Mechanical Positive Displacement Flow Meter

- ±0.2 % accuracy

- Strong applicability to viscosity changes.

- Good for fuel delivery trucks and tankers.

Accuracy

±0.2 %

Measuring Range

25 to 3000 L/Min

Medium Temperature Range

-20~+250 ℃

Max. Process Pressure

25 bar (350 psi)

Check All Positive Displacement Flow Meters

Key Advantages of PD Flow Meter Measuring Oils

- Compatibility with Diverse Oil Types

- High Accuracy and Precision

- Precise Batch Control

- No straight-pipe requirements

Postive displacement flowmeter is best suited for measuring:

- High-viscosity oils (e.g., heavy fuels, lubricants)

- Clean oils (e.g., refined fuels, synthetic lubricants)

- Oils with variable viscosity (e.g., crude oil, biofuels)

- Oils in custody transfer or industrial applications

Coriolis Flow Meters

Coriolis Mass Flow Meter W Shape (MTD-ACMW)

Accuracy

±0.1 %; ±0.15 %; ±0.2 %; ±0.5 %

Measuring Range

8-1500000 kg/h (17 – 3306930 lb/h)

Medium Temperature Range

Integrate Type: (-50~+125)℃

Split Type: (-200~+350)℃

Max. Process Pressure

250 bar (3626 psi)

Measuring tube

Austenitic stainless steel (316/316L), and others on request

Coriolis Mass Flow Meter C Shape (MTD-ACMC)

Accuracy

±0.1 %; ±0.15 %; ±0.2 %; ±0.5 %

Measuring Range

500-200000 kg/h (1100-440900 lb/h)

Medium Temperature Range

Integrate Type: (-50~+125)℃

Split Type: (-200~+350)℃

Max. Process Pressure

250 bar (3626 psi)

Measuring tube

Austenitic stainless steel (316/316L), and others on request

Coriolis Mass Flow Meters for Advanced Process Applications (MASS-A)

Accuracy

Standard: ±0.5 %, Optional: ±0.2 %; ±0.15 %

Measuring Range

0-30000 kg/min (0-66138 lb/min)

Medium Temperature Range

-40 to 185°F (-40 to 85°C)

Max. Process Pressure

100 bar (1450.38 psi)

Measuring tube

Austenitic stainless steel (316L), Hastelloy C, and others on request

Check All Coriolis Flow Meters

Key Advantages of Coriolis Flow Meter Measuring Oils

- Measures mass flow directly (±0.1% accuracy) unaffected by changes in density, temperature, or pressure.

- No moving parts – low maintenance and long lifespan.

- Multi-parameter output (mass flow, density, temperature).

Coriolis flowmeter is best suited for measuring:

- Any oil type (light to heavy) requiring direct mass flow measurement.

- Custody transfer, billing, or processes needing precise density tracking.

- Oils with varying viscosity, temperature, or composition (e.g., blended fuels).

Turbine Flow Meters

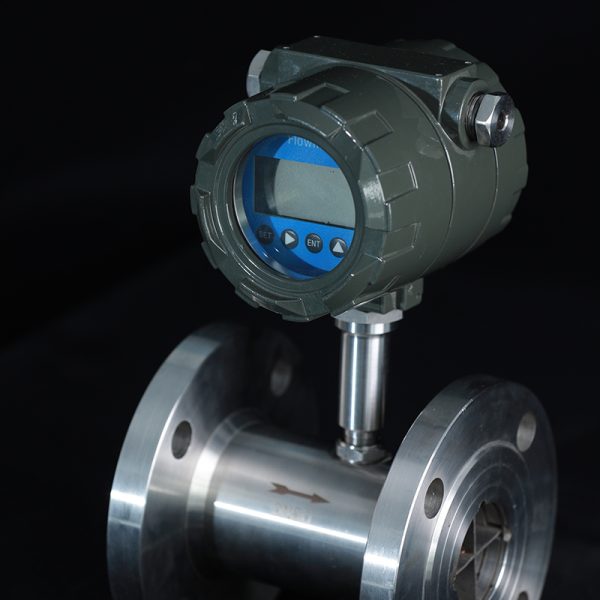

Liquid Turbine Flow Meter (LWGYMT-100)

Accuracy

Standard: ±1 %, Optional: ±0.5 %

Measuring Range

0.04 to 800 m³/h

Medium Temperature Range

standard: -20 TO 120 °C (–4 to +248 °F)

Max. Process Pressure

250 bar (3625.95 psi)

High Accuracy Liquid Turbine Flow Meter (LWGYMT-AJWL)

Accuracy

±0.2 %; ±0.5 %

Measuring Range

0.004 to 1800 m³/h

Medium Temperature Range

standard: -196 TO 180 °C (−320.8 to +356 °F)

Max. Process Pressure

350 bar

High Pressure Liquid Turbine Flow Meter (LWGYMT-P)

Accuracy

Standard: ±1 %, Optional: ±0.5 %

Measuring Range

0.4 to 800 m³/h

Medium Temperature Range

standard: -20 TO 120 °C (–4 to +248 °F)

Max. Process Pressure

250 bar (3625.95 psi)

Check All Turbine Flow Meters

Key Advantages of Turbine Flow Meter Measuring Oils

- Lower upfront cost compared to PD or mass flow meters.

- minimal maintenance in clean fluids

Turbine flowmeter is best suited for:

- High-flow, low-viscosity oils in cost-sensitive applications.

Factors to Consider When Choosing an Oil Flow Meter

Viscosity of the Oil

Oil comes in various viscosities, from light crude oil to heavy fuel oil. Some flow meters are better suited for low-viscosity oils, while others are designed to handle high-viscosity fluids. Understanding the oil’s viscosity range is essential for choosing a flow meter that will provide accurate readings.

Flow Rate Range

Flow rate can vary significantly depending on the type of oil being measured and the application. Some meters perform better at high flow rates, while others are optimized for lower flow rates. Accurately determining the expected flow rate is essential for ensuring the meter works effectively within its operating range.

Pressure and Temperature

In industrial settings, oil is often subject to high pressures and temperatures. Flow meters need to be able to withstand these conditions without compromising accuracy or longevity. Ensure the meter you select is compatible with the temperature and pressure levels of your process.

Accuracy and Calibration

Depending on the application, the required level of accuracy may vary. For example, fiscal metering for oil trading requires highly accurate meters, while general process monitoring may allow for more flexibility. Consider the accuracy ratings of each meter and any required calibration procedures to maintain long-term reliability.

Maintenance and Durability

Some flow meters are more prone to wear and tear, especially when measuring oils with high viscosity or in challenging environments. It’s important to consider the maintenance requirements and long-term durability of the flow meter, particularly in industrial settings where downtime can be costly.

Installation Requirements

The installation environment can also dictate the type of meter you choose. Some flow meters require in-line installation with straight pipe runs to ensure accurate measurement, while others, like ultrasonic meters, offer non-intrusive installation options. Make sure the meter fits into your system’s layout with minimal disruption.

Budget

Flow meters can vary greatly in price, depending on their accuracy, technology, and durability. Higher-end meters typically offer more features and better long-term performance, but they come with a higher upfront cost. Consider the total cost of ownership, including maintenance, calibration, and lifespan.

Choosing the Right Oil Flow Meter for Your Application

For high-viscosity oils or low flow rates

Choose positive displacement flow meters for their accuracy and reliability in handling thick oils.For high-precision applications

Use Coriolis flow meters, especially when mass flow measurement and varying conditions are important.For low-viscosity oils at high flow rates

Turbine flow meters are a cost-effective and accurate solution.