Steam is one of the most widely used energy carriers in industries around the world. From power generation to food processing, steam provides heat, drives turbines, and supports countless industrial processes. Measuring steam accurately is vital for optimizing energy usage, improving process control, and reducing costs — and that’s where medidores de caudal de vapor play an essential role.

This article explains the characteristics of steam, why measuring it is important, the most recommended flow meter types for steam, and how to choose the right one for your application.

Índice

You may also insterested in:

Characteristics of Steam and Its Industrial Applications

What Is Steam?

Steam is water vapor produced when water boils and changes from liquid to gas at a given temperature and pressure. Depending on its state and pressure, steam can exist in three common forms in industrial use:

- Saturated steam: Steam in equilibrium with liquid water at a given pressure. It contains no superheat and is widely used in heating and sterilization.

- Superheated steam: Steam that is heated beyond the saturation temperature, with higher energy content and no moisture. It is ideal for power generation and turbine systems.

- Wet steam: A mixture of water droplets and vapor, typically undesirable in precision processes due to its variable energy content.

Steam Characteristics

Steam has several unique physical properties that make flow measurement challenging:

- High temperature and pressure — typical saturated steam ranges from 100°C at atmospheric pressure to over 300°C at higher pressures.

- High energy density — small changes in flow can represent large variations in energy transfer.

- Variable density — steam density changes significantly with pressure and temperature, requiring compensation during measurement.

Applications of Steam

Steam is a versatile medium used across numerous industries:

- Power generation: To drive turbines and generate electricity.

- Petrochemical and chemical industries: For heating reactors, distillation, and drying processes.

- Food and beverage: For sterilization, cooking, and pasteurization.

- Pharmaceutical manufacturing: To maintain sterile conditions and clean-in-place (CIP) systems.

- HVAC and building systems: For heating and humidification.

- Textile and pulp industries: For drying and process heating.

What Is a Steam Flow Meter

A steam flow meter is an instrument designed to measure the flow rate of steam within a pipeline. Unlike liquid or gas flow measurement, steam flow measurement must consider pressure, temperature, and density variations, which directly affect flow accuracy.

Why Measuring Steam Flow Is Important

- Energy Management: Steam is one of the most expensive utilities in a plant. Monitoring its flow helps identify energy losses, inefficiencies, and leaks.

- Process Control: Consistent steam supply ensures stable product quality, particularly in temperature-sensitive processes.

- Safety and Compliance: Over- or under-delivery of steam can cause system pressure imbalances, impacting safety and regulatory compliance.

- Cost Allocation: Accurate flow data allows fair distribution of energy costs among different departments or processes.

- Maintenance Planning: Tracking flow over time helps detect anomalies that could indicate blockages, leaks, or equipment wear.

In short, a precise steam flow meter is essential for efficiency, safety, and sustainability.

What types of flow meter are recommended for steam?

Steam can be difficult to measure because of its temperature, pressure, and phase changes. Not all flow meters can withstand such conditions. Below are the most commonly used and reliable types for steam flow measurement, each with its own strengths.

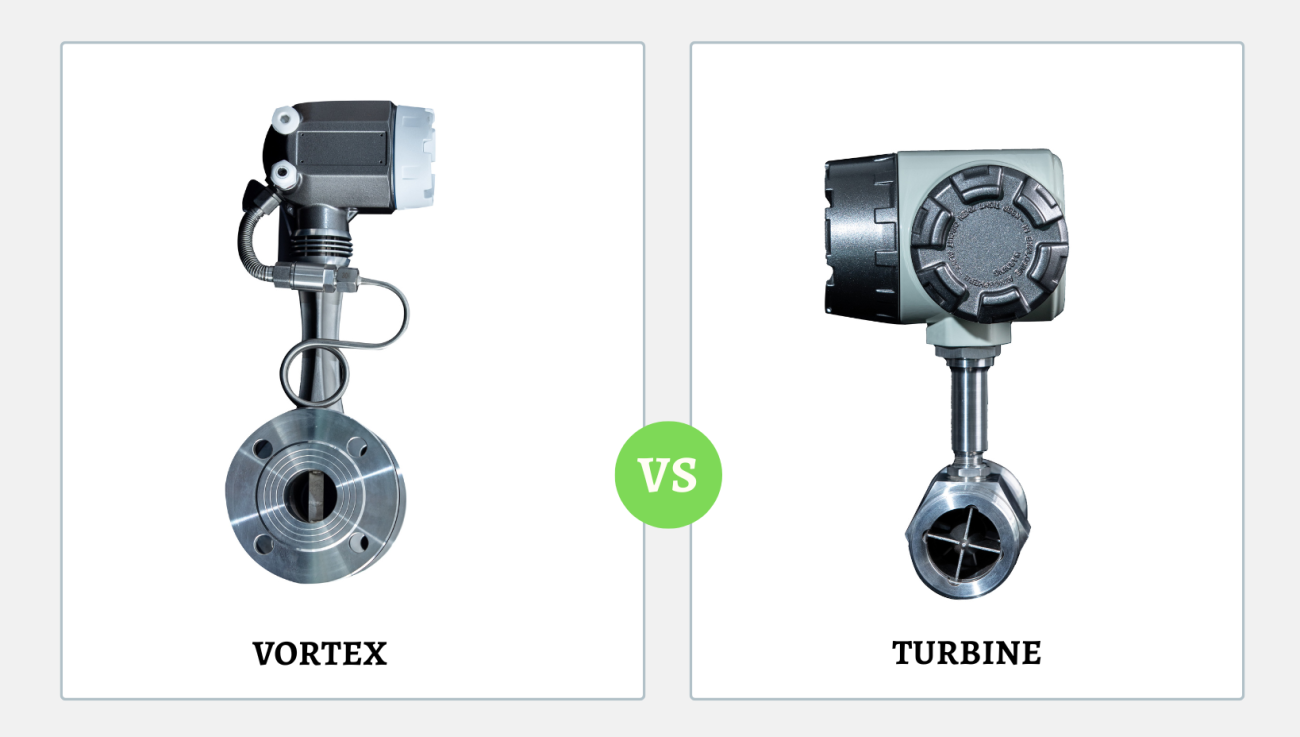

Medidores de caudal Vortex

Princípio de funcionamento:

When steam passes a bluff body (obstacle) in the flow path, vortices are alternately shed on each side. The frequency of these vortices is proportional to the flow velocity.

Vantagens:

- No moving parts → manutenção reduzida

- Funciona bem para saturated and superheated steam

- Provides good accuracy and repeatability

Desvantagens:

- Not suitable for low-flow steam due to insufficient vortex formation

Typical Applications:

General industrial steam flow measurement, utilities, and HVAC systems.

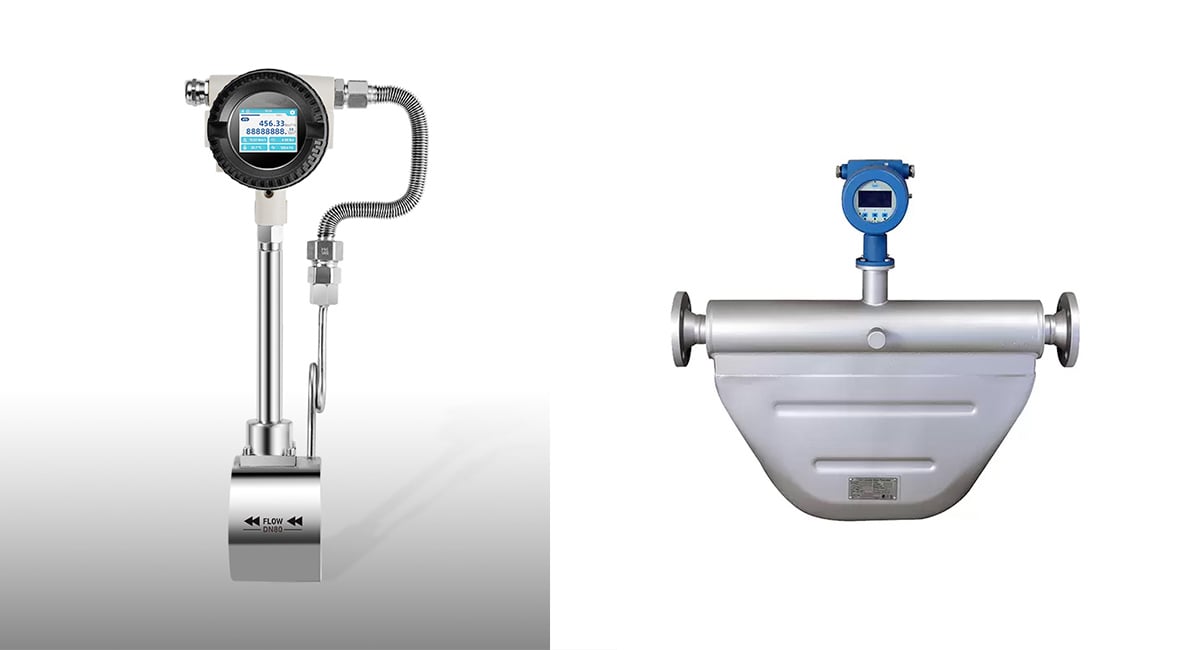

Vortex Steam Flow Meter from Metlan Instruments

- The turndown range ratio is 53:1, which exceeds the traditional vortex flow meters.

- Suitable for measuring dirty and wet compressed air, oxygen, natural gas and other industrial gases, steam, and etc.

- Wide measuring range, the low measuring limit can reach 1.5m/s.

- Integrates pressure and temperature sensors to monitor online gas pressure and temperature.

- No moving parts, low pressure drop.

Medidores de caudal mássico Coriolis

Princípio de funcionamento:

Steam (as a moving mass) passes through vibrating tubes. The Coriolis effect causes a phase shift proportional to the mass flow rate.

Vantagens:

- Medição direta do caudal mássico independent of temperature and pressure

- Extremely high accuracy

- Also provides density and temperature data

Desvantagens:

- Custo elevado

- Limited to low to medium flow rates and specific high-pressure designs

Typical Applications:

Precision measurement in chemical, pharmaceutical, and research facilities where accuracy outweighs cost.

Metlan Instruments Coriolis Flow Meter

- Elevada precisão até ±0,1 %, boa fiabilidade

- Bom desempenho de estabilidade zero e anti-interferência

- Sem partes móveis, sem necessidade de manutenção

- Comunicação digital múltipla, incluindo Hart

Medidores de caudal de pressão diferencial (DP)

Princípio de funcionamento:

DP flow meters use an orifice plate, Venturi tube, or flow nozzle to create a pressure drop proportional to the square of the steam flow rate. A differential pressure transmitter measures the pressure difference, from which the flow is calculated.

Vantagens:

- Proven and widely accepted technology

- Adequado para both saturated and superheated steam

- Can be used in large-diameter pipes and high-pressure systems

Desvantagens:

- Requer pressure and temperature compensation for accuracy

- Flow restriction causes energy loss

- Maintenance needed for orifice plate wear

Typical Applications:

Power plants, refineries, and heating networks using medium to high-pressure steam.

Pitot Tube Gas Flow Meter from Metlan Instruments

- Aplicável à medição de ar sujo e húmido

- A auto-calibração em linha reduz o desvio de dados

- alta sensibilidade, o limite inferior é de 5 Nm/s

- Rácio de abertura ampla de 1:60

- Medição de caudal bidirecional

- Integra sensores de pressão e temperatura para monitorizar a pressão e a temperatura do gás em linha

- Sem partes móveis, baixa queda de pressão

- Não é afetado pela vibração da tubagem

How to Choose the Right Steam Flow Meter

Selecting the proper flow meter depends on several key parameters. Below are essential considerations to ensure accuracy, reliability, and cost-effectiveness.

Steam Type: Saturated vs. Superheated

- Saturated steam: DP or vortex meters are usually the best choice because they can handle condensate and varying densities.

- Superheated steam: Vortex or Coriolis meters are ideal due to their ability to handle high temperature and consistent vapor conditions.

Flow Range and Pipe Size

- For large-diameter pipes e caudais elevados, DP and Pitot tube meters are economical and robust.

- For low-flow precision applications, a Medidor de caudal mássico Coriolis provides unparalleled accuracy.

Pressure and Temperature Conditions

Confirm the meter’s materials and design can withstand the maximum steam temperature and pressure in your system. For example, superheated steam at 3 MPa has a temperature of about 234°C, while at 6 MPa it can exceed 275°C.

Accuracy and Control Requirements

- If you need precise energy balance ou controlo do processo, go for Coriolis ou medidores de caudal de vórtice.

- If only general monitoring is required, DP ou Pitot tube meters provide reliable and cost-effective solutions.

nstallation and Maintenance

- Choose a meter that matches your available straight-pipe length, orientation, and maintenance capability.

- Non-intrusive options like vortex meters reduce downtime and simplify installation.

Budget and Lifecycle Cost

Enquanto Medidores Coriolis offer the best performance, they are also the most expensive. Vórtice e DP meters deliver excellent balance between cost and reliability for most steam applications. Always consider total cost of ownership, not just the purchase price.

Steam is an indispensable utility across industries, but its high temperature, variable density, and pressure make accurate flow measurement challenging. Choosing the right steam flow meter ensures energy efficiency, process stability, and operational safety. When selecting your instrument, always consider steam type, operating conditions, desired accuracy, and budget. The right steam flow meter not only improves process control but also delivers substantial energy savings and sustainability benefits.

By the way, we’re glad to announce that we just became a listed company on automationinside.com!