No mundo diversificado da medição de caudal, a precisão e a fiabilidade são fundamentais, especialmente quando se lida com fluidos viscosos ou difíceis. Entre a gama de tecnologias de caudalímetros, a caudalímetro de engrenagem oval stands out as a stalwart in industries requiring precise volumetric measurement. Known for their robust design and exceptional accuracy, these meters are a cornerstone in sectors ranging from petroleum to food production, espeically for oil flow measurement.

Índice

O que é um medidor de caudal de engrenagem oval?

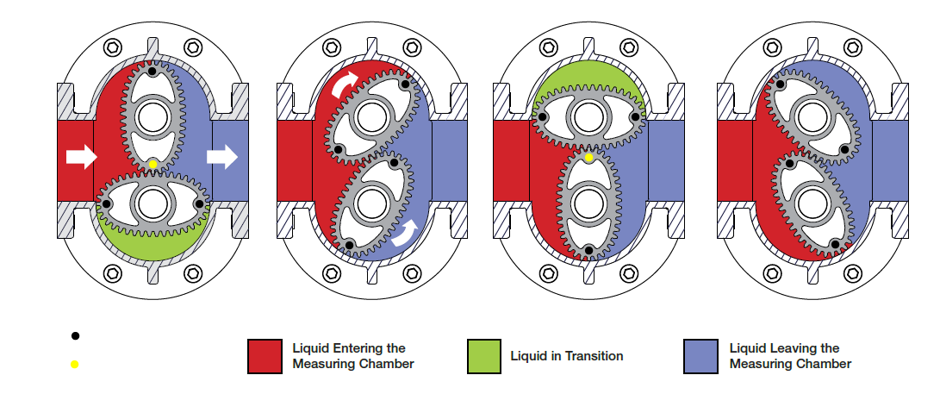

Um medidor de caudal de engrenagem oval é um caudalímetro de deslocamento positivo (PD) que mede o caudal volumétrico de líquidos através do aprisionamento e transferência de volumes fixos de fluido entre engrenagens ovais rotativas. À medida que o fluido passa pelo medidor, as engrenagens rodam em direcções opostas, criando câmaras seladas que isolam quantidades específicas de fluido. O número de rotações corresponde diretamente ao volume total de fluido que passa, garantindo uma elevada precisão mesmo com caudais ou viscosidades flutuantes.

Componentes principais:

- Engrenagens ovais: Duas engrenagens de precisão com perfis ovais que se engrenam sem contacto.

- Câmara de medição: A caixa onde as engrenagens rodam, criando bolsas estanques de fluido.

- Sensores: Detetar a rotação das engrenagens para calcular o caudal (por exemplo, captadores magnéticos ou codificadores ópticos).

- Ecrã de saída: Mostra dados de fluxo em tempo real, volume totalizado e outras métricas.

Princípio de funcionamento dos medidores de caudal de engrenagem oval

O funcionamento de um medidor de caudal de engrenagem oval depende da interação mecânica entre as suas engrenagens e o fluido. Aqui está uma descrição passo a passo:

- Entrada de fluidos: O líquido entra no orifício de entrada do medidor, preenchendo o espaço entre as engrenagens e as paredes da câmara.

- Rotação da engrenagem: A pressão do fluido força as engrenagens ovais a rodar. Ao rodarem, as engrenagens formam bolsas estanques de fluido entre os seus lóbulos e a câmara.

- Captura de volume: Cada rotação retém um volume fixo de fluido. Por exemplo, se cada bolsa contiver 10 mL e as engrenagens completarem 100 rotações, o volume total medido é de 1.000 mL.

- Deslocamento e saída: O fluido retido é transportado para a porta de saída e os sensores traduzem as rotações da engrenagem em sinais eléctricos. Estes sinais são processados para indicar o caudal (por exemplo, litros por minuto) e o volume acumulado.

Porquê engrenagens ovais?

A forma oval assegura uma rotação suave e contínua com o mínimo de fricção. Ao contrário das engrenagens circulares, o design oval cria câmaras grandes e pequenas alternadas, permitindo uma medição volumétrica precisa sem pulsação.

Meios adequados para medidores de caudal de engrenagem oval

Os medidores de caudal de engrenagem oval são excelentes com tipos específicos de fluidos, particularmente os de viscosidade mais elevada. Segue-se uma análise da sua compatibilidade:

Fluidos ideais:

- Líquidos de alta viscosidade:

- Óleos (hidráulicos, lubrificantes, alimentares), combustíveis, xaropes, melaços e resinas.

- Viscosidades que variam de 1 cP a 100.000 cP.

- Fluidos limpos e não abrasivos:

- Produtos químicos, solventes e produtos farmacêuticos.

- Fluidos isentos de partículas para evitar o encravamento das engrenagens.

- Fluidos estáveis à temperatura:

- A maioria dos modelos funciona entre 20°C a 150°C (-4°F a 302°F), embora as versões especializadas suportem extremos.

Fluidos inadequados:

- Meios abrasivos ou corrosivos: As partículas ou os produtos químicos agressivos podem desgastar as engrenagens (exceto se forem fabricadas com materiais endurecidos, como o aço inoxidável ou a cerâmica).

- Fluidos multifásicos: As misturas de gás e líquido (por exemplo, bebidas gaseificadas) perturbam a vedação e a precisão.

- Fluidos de baixa viscosidade: Os fluidos semelhantes à água podem passar pelas engrenagens, reduzindo a precisão.

Aplicações dos medidores de caudal de engrenagem oval

Os medidores de engrenagem oval prosperam em indústrias onde a medição volumétrica precisa é crítica. Abaixo estão os principais sectores e casos de utilização:

1. Petróleo e indústria petrolífera

- Distribuição de combustível: Accurately measures diesel, gasoline, and aviation fuel flow at refineries or gas stations.

- Mistura de lubrificantes: Assegura rácios precisos de aditivos nos óleos lubrificantes.

2. Alimentação e bebidas

- Xarope e óleos alimentares: Mede ingredientes como o xarope de milho ou o azeite durante a produção.

- Processamento de produtos lácteos: Rastreia leite, natas ou chocolate líquido em ambientes de elevada pureza.

3. Fabrico de produtos químicos

- Dosagem de solventes: Controla a adição de produtos químicos em reacções ou formulações.

- Transferência de resina: Monitorização de resinas viscosas em revestimentos ou adesivos.

4. Produtos farmacêuticos

- Processamento em lote: Assegura volumes exactos de ingredientes farmacêuticos activos (API).

- Aplicações sanitárias: Em conformidade com as normas FDA/USP para o manuseamento higiénico de líquidos.

5. Marinha e transportes

- Medição de combustível de bancas: Monitoriza o consumo de combustível dos navios.

- Sistemas hidráulicos: Controlo do fluxo de óleo em máquinas pesadas.

Vantagens dos medidores de caudal de engrenagem oval

- Elevada precisão: ±0,2% a ±1% de leitura, mesmo com caudais viscosos ou variáveis.

- Queda de pressão mínima: A conceção eficiente evita perdas de energia significativas.

- Ampla gama de viscosidade: Funciona bem com fluidos espessos ou pegajosos.

- Simplicidade mecânica: Não é necessária alimentação externa para os modelos básicos (contadores mecânicos).

Limitações e considerações

- Requisitos de manutenção: As peças móveis (engrenagens, rolamentos) devem ser inspeccionadas e lubrificadas periodicamente.

- Pureza do fluido: As partículas ou detritos podem danificar as engrenagens; instale filtros, se necessário.

- Sensibilidade à temperatura: A expansão térmica pode afetar a calibração em condições extremas.

Como escolher um medidor de caudal de engrenagem oval

- Compatibilidade de fluidos: Adaptar a engrenagem/material (por exemplo, latão, aço inoxidável) às propriedades químicas do fluido.

- Gama de caudal: Selecione um medidor dimensionado para os seus caudais mínimo e máximo (por exemplo, 0,1-100 LPM).

- Viscosidade: Confirme se a gama de viscosidade do medidor está de acordo com o seu fluido.

- Necessidades de produção: Escolha entre contadores mecânicos, sinais de 4-20 mA ou interfaces digitais (por exemplo, Modbus).

- Certificações: Assegurar a conformidade com as normas do sector (por exemplo, ATEX para ambientes explosivos).

Os medidores de caudal de engrenagem oval são um testemunho do valor duradouro do engenho mecânico num mundo cada vez mais digital. A sua capacidade de fornecer medições precisas e fiáveis para fluidos viscosos e difíceis torna-os indispensáveis em indústrias onde a precisão tem um impacto direto na qualidade, segurança e rentabilidade.

Ao compreender os seus princípios de funcionamento, fluidos compatíveis e aplicações ideais, os engenheiros e operadores podem aproveitar estes medidores para otimizar os processos, reduzir o desperdício e cumprir as rigorosas normas regulamentares.