Steam Flow Meters

A steam flowmeter is a device used to measure steam flow, accurately determining the volumetric or mass flow of steam through various principles. As a common thermal energy medium in industrial processes, steam flow measurement plays a vital role in energy management, production control, and billing allocation. Steam is widely used across multiple industries, including chemicals, food and beverages, pharmaceuticals, power generation, paper manufacturing, textiles, metallurgy, HVAC, oil and gas, and steelmaking. In these sectors, steam flowmeters help enhance production efficiency, optimize energy usage, reduce costs, and ensure stability and precision in production processes.

Steam Vortex Flow Meter Anti-vibration (LUGBMT-VS)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Steam/Gas: 3.5 to 20347.2 m³/h

Medium Temperature Range

Standard: –40 to +160 °C

High/low temperature (option): –180 to +350 °C

Max. Process Pressure

63 bar (913.74 psi)

Vortex Flow Meters (LUGBMT-100)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Liquid: 0.8 to 3500 m³/h

Steam, gas: 5 to 18000 m³/h

Medium Temperature Range

Standard: –40 to +260 °C (–40 to +480 °F)

High/low temperature (option): –200 to +400 °C (–328 to +750 °F)

Max. Process Pressure

100 bar (1450.38 psi)

Vortex Flow Meters with Temperature and Pressure Compensation (LUGBMT-C)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Liquid: 0.8 to 3500 m³/h

Steam, gas: 5 to 18000 m³/h

Medium Temperature Range

Standard: –40 to +260 °C (–40 to +480 °F)

High/low temperature (option): –200 to +350 °C (–328 to +660 °F)

Max. Process Pressure

100 bar (1450.38 psi)

Vortex Flow Meter for High Pressure (LUGBMT-P)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Liquid: 0.8 to 3500 m³/h

Steam, gas: 5 to 18000 m³/h

Medium Temperature Range

Standard: –40 to +260 °C (–40 to +480 °F)

High/low temperature (option): –200 to +350 °C (–328 to +660 °F)

Max. Process Pressure

250 bar (3625.95 psi)

Vortex Flow Meter for High Temperature Medium (LUGBMT-H)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Liquid: 0.8 to 3500 m³/h

Steam, gas: 5 to 18000 m³/h

Medium Temperature Range

–200 to +400 °C (–328 to +750 °F)

Max Process Pressure

100 bar (1450.38 psi)

Coriolis Mass Flow Meter W Shape (MTD-ACMW)

Accuracy

±0.1 %; ±0.15 %; ±0.2 %; ±0.5 %

Measuring Range

8-1500000 kg/h (17 – 3306930 lb/h)

Medium Temperature Range

Integrate Type: (-50~+125)℃

Split Type: (-200~+350)℃

Max. Process Pressure

250 bar (3626 psi)

Measuring tube

Austenitic stainless steel (316/316L), and others on request

Coriolis Mass Flow Meter C Shape (MTD-ACMC)

Accuracy

±0.1 %; ±0.15 %; ±0.2 %; ±0.5 %

Measuring Range

500-200000 kg/h (1100-440900 lb/h)

Medium Temperature Range

Integrate Type: (-50~+125)℃

Split Type: (-200~+350)℃

Max. Process Pressure

250 bar (3626 psi)

Measuring tube

Austenitic stainless steel (316/316L), and others on request

Orifice Plate Flowmeter (MTKB-O)

Accuracy

±0.075%

Medium Temperature Range

standard: -40 TO 850 °C (–40 to +1562 °F)

Max. Process Pressure

400 bar (5801.52 psi)

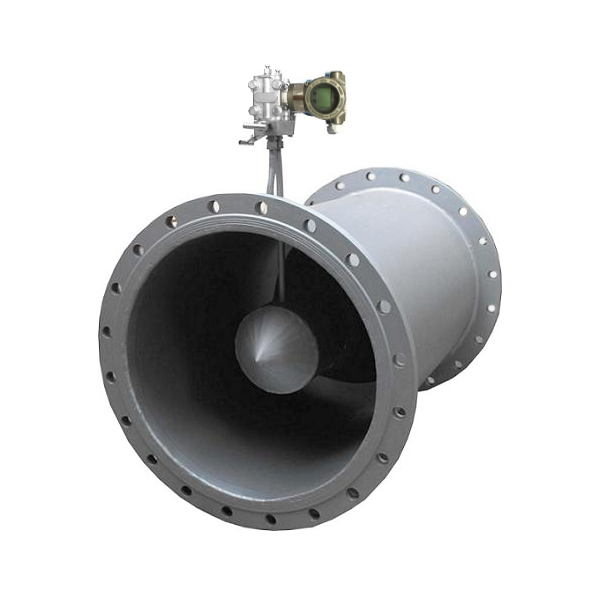

V Cone Different Pressure Flowmeter (MTKB-V)

Accuracy

±0.5%

Medium Temperature Range

standard: -40 TO 850 °C (–40 to +1562 °F)

Max. Process Pressure

420 bar (6091.6 psi)

Key Factors for Selecting a Steam Flowmeter:

1. Define Measurement Requirements:

- Type of Steam: Determine the type of steam being measured, such as saturated steam or superheated steam, as different types have varying requirements for flowmeters.

- Temperature and Pressure: Identify the temperature and pressure range of the steam to ensure the selected flowmeter can withstand these conditions.

- Flow Range: Ensure the flowmeter’s measuring range covers the actual operational needs.

2. Consider Application Scenarios:

- Different application scenarios demand different requirements, such as resistance to high temperatures, high pressures, or corrosive environments.

3. Installation and Maintenance:

- Installation Conditions: Evaluate the pipe dimensions, connection types, and installation locations to ensure easy installation and maintenance.

- Maintenance and Calibration: Steam flowmeters require regular maintenance and calibration, so choosing a device that is easy to maintain is essential.

4. Comprehensive Cost-Effectiveness:

- Select a cost-effective flowmeter based on actual needs and budget, ensuring it meets production requirements while minimizing procurement and maintenance costs.

Types of Steam Flowmeters and Their Applications:

Type | Recommended Scenarios | Advantages | Considerations |

Differential Pressure Flowmeter | Saturated steam, superheated steam, high-pressure steam | Mature technology, suitable for large diameter and high-pressure pipelines | Requires temperature and pressure compensation for accuracy, may introduce pressure loss |

Vortex Flowmeter | Industrial steam heating, power plants | No moving parts, low maintenance, handles varying flow rates and pressure/temperature | Accuracy decreases at low flow rates, sensitive to installation conditions |

Thermal Mass Flowmeter | Low-flow superheated steam, precise metering | Direct mass flow measurement without compensation, ideal for low flow rates | Sensitive to impurities, not suitable for high-pressure or large flow applications |

Swirl Vortex Flowmeter | Medium to high-pressure steam applications | Built-in temperature/pressure compensation, compact size, easy installation | Sensitive to vibrations, unsuitable for low flow or pulsating flows |

Coriolis Mass Flowmeter | High-precision energy metering, steam distribution and billing | Direct mass flow measurement, highly accurate, ideal for precise energy accounting | Sensitive to impurities, higher cost, suitable for stable flow scenarios |

Summary of Flowmeters for Different Steam Applications:

1. Boiler Steam Outlet (Saturated Steam)

Recommended Flowmeters: Vortex Flowmeter, Differential Pressure Flowmeter

- Vortex Flowmeter: Simple structure, no moving parts, suitable for long-term stable monitoring.

- Differential Pressure Flowmeter: Performs well under high-temperature and high-pressure conditions, meeting the needs of industrial boiler outlets.

2. Distributed Steam Network Monitoring

Recommended Flowmeter: Ultrasonic Flowmeter

- Ultrasonic Flowmeter: Non-invasive installation, supports remote data collection, ideal for smart monitoring of extensive pipeline networks.

3. Steam Energy Metering and Distribution

Recommended Flowmeters: Coriolis Mass Flowmeter, Thermal Mass Flowmeter

- Coriolis Mass Flowmeter: Directly measures mass flow without compensation, ideal for high-precision energy metering.

- Thermal Mass Flowmeter: Provides real-time temperature and pressure compensation, suitable for cost allocation and metering.

4. Challenging Industrial Environments (High Temperature, High Pressure, Complex Media)

Recommended Flowmeters: Differential Pressure Flowmeter, Swirl Vortex Flowmeter

- Differential Pressure Flowmeter: Stable performance under extreme conditions of high temperature and pressure.

- Swirl Vortex Flowmeter: Adapts well to steam quality variations or mixed media, offering high reliability.

5. Small Equipment or Localized Steam Flow Monitoring

Recommended Flowmeters: Coriolis Mass Flowmeter, Orifice Plate Flowmeter

- Coriolis Mass Flowmeter: High accuracy in low-flow scenarios, suitable for localized monitoring.

- Orifice Plate Flowmeter: Simple structure, low cost, ideal for small-scale setups with budget constraints.