Rotameters Flow Meter

A Rotameter is a type of variable area flow meter that measures the flow rate of fluids (liquids or gases) in a vertical tube. The device operates based on gravity and the fluid’s dynamic forces. The term “Rotameter” is derived from the rotation of the float, which is used to indicate the flow rate. Rotameters are commonly used because they are simple, cost-effective, and require no external power source. They provide a direct visual indication of the flow rate, making them easy to use and maintain.

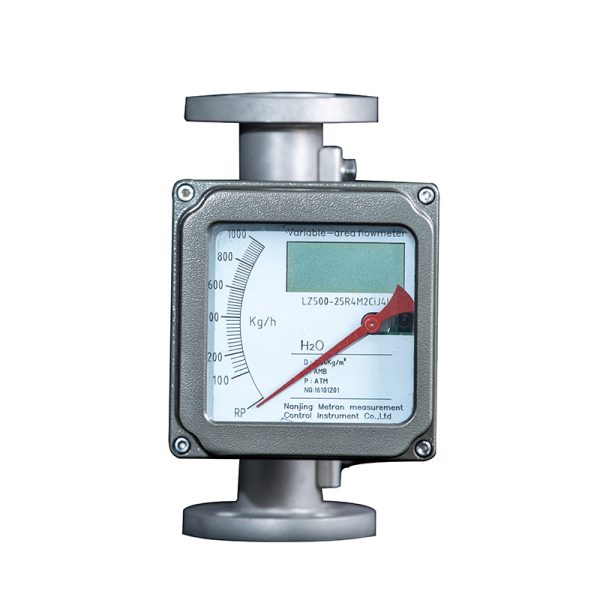

Rotameter Metal Variable Area Flow Meters (MTLZ-M)

Accuracy

Standard: ±2.5 %, Optional: ±1.5 %

Measuring Range

Liquid:1.0~150000l/h

Gas:0.05~3000m³/h

Medium Temperature Range

standard: -80 TO 350 °C (–112 to +662 °F)

Max. Process Pressure

DN15-50:200 bar (2900.76 psi)

DN80-100: 100 bar (1450.38 psi)

Working Principles of Rotameters

The working of a Rotameter is based on the principles of gravity and fluid dynamics:

- The fluid enters the Rotameter through the bottom inlet and flows upward through the tapered tube.

- The float inside the tube is lifted by the force of the fluid flow.

- As the float rises, the increasing cross-sectional area of the tube reduces the velocity of the fluid and increases the flow area.

- The float reaches a position where the upward force exerted by the fluid equals the downward gravitational force acting on the float.

- The position of the float is proportional to the flow rate and is read against the calibrated scale on the tube.

Key forces involved:

- Buoyancy: The upward force exerted by the fluid.

- Gravitational Force: The weight of the float pulling it downward.

- Drag Force: The resistance created by the flow around the float.

Construction of Rotameters

A Rotameter consists of the following primary components:

- Tapered Tube:

- Made of transparent material like glass or plastic (for visible flow) or metal (for durability in high-pressure or opaque conditions).

- The tube is vertically aligned, with the diameter increasing from bottom to top.

- Float:

- A solid object (usually metal, plastic, or ceramic) inside the tube.

- The float moves freely up and down in response to the fluid flow rate.

- The shape of the float varies depending on the application (e.g., spherical, ellipsoidal, or conical).

- Scale or Markings:

- Graduations or markings on the tube indicate the flow rate.

- Calibration is specific to the fluid being measured (considering viscosity, density, and pressure).

- Inlet and Outlet Connections:

- The tube has an inlet at the bottom and an outlet at the top, allowing the fluid to flow vertically upward.

- Flow Control Valve (Optional):

- Some Rotameters are equipped with a valve to regulate the flow rate.

Advantages of Rotameters

- Simple Design:

- Easy to install, operate, and maintain.

- Requires no external power supply.

- Cost-Effective:

- Economical compared to other flow measurement devices.

- Direct Visual Indication:

- Provides an immediate and intuitive reading of the flow rate.

- Versatile:

- Suitable for a wide range of fluids, including liquids and gases.

- Durability:

- Metal and armored Rotameters are designed to withstand harsh industrial conditions.

Gas Flow Meters | Oil Flow Meters | Pitot Tube Flow Meters | Flow Meter Controllers | Coriolis Flow Meters | Vortex Flow Meters | Ultrasonic Gas Flow Meters | Thermal Mass Flow Meters | Turbine Flow Meters | Magnetic Flow Meters | Differential Pressure Flow Meters