Measuring and regulating gas or liquid flow with precision is fundamental in industries ranging from semiconductors to biotech. Among the most reliable instruments for this task is the Mass Flow Controller (MFC). This guide will walk you through what MFCs are, their major types and operational principles, their applications.

جدول المحتويات

What Is a Mass Flow Controller?

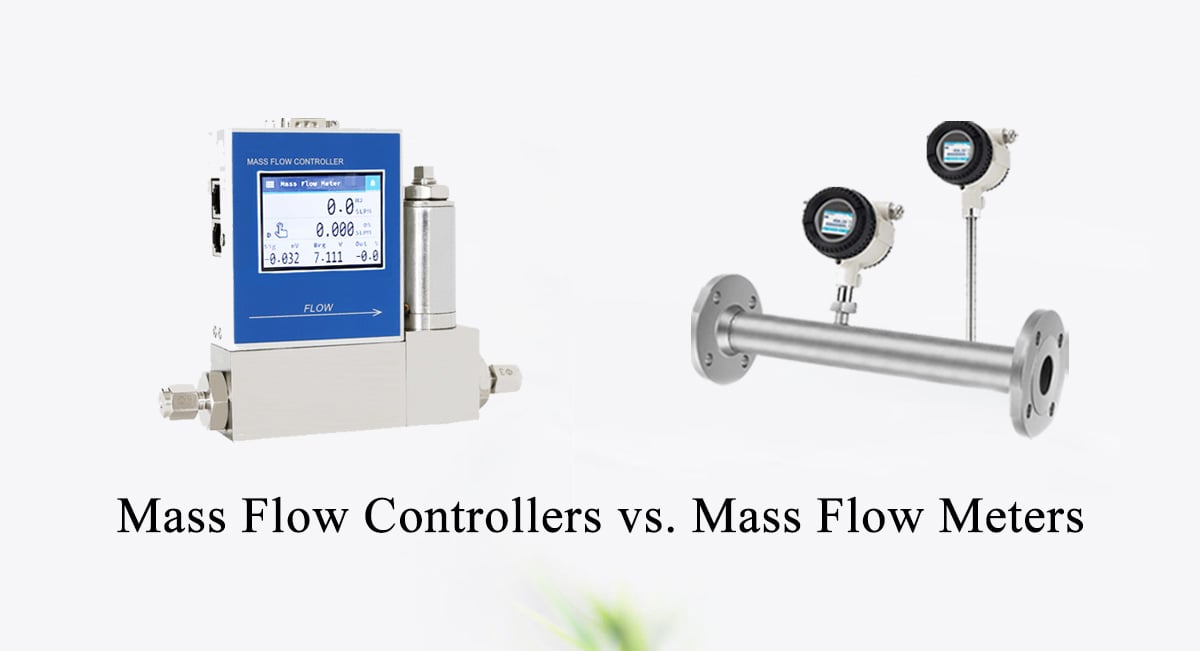

A Mass Flow Controller (MFC) is a fluid control device designed to measure and regulate flow by mass, not just volume. Unlike traditional mass flow meters, MFCs contain an internal valve mechanism and a control loop that maintains flow at a specific setpoint. This makes them ideal for systems that require precise, stable delivery of fluids under varied conditions.

Key characteristics of MFCs:

- Measures and actively controls flow

- Operates with high repeatability and accuracy

- Suitable for very low flow rates, including SCCM (standard cubic centimeters per minute)

- Offers digital and analog communication for automation integration

How Does Mass Flow Controllers Work

The main components of mass flow controllers include a flow sensor, a control valve, and an electronic controller. The flow sensor continuously measures the actual mass flow of the fluid passing through the device, often using thermal or differential pressure principles. This measurement is sent as a signal to the electronic controller, which compares it to a user-set target flow rate.

If the measured flow deviates from the target, the controller automatically adjusts the control valve to increase or decrease the flow, maintaining a stable and accurate output. This feedback loop operates in real time, allowing the MFC to respond quickly to changes in pressure, temperature, or other process conditions.

Types of Mass Flow Controllers

Thermal Mass Flow Controllers

كيف تعمل: Measure the heat transfer away from a heated sensor element; the heat loss relates directly to the mass flow. Here’s a case study of thermal mass flow controller.

الأفضل لـ Clean, dry gases at low flow.

الإيجابيات:

- Compact, highly sensitive, no moving parts

- Excellent accuracy in low-flow measurements

السلبيات:

- Sensitive to gas composition and moisture

- Requires recalibration for different gases

Thermal Gas Mass Flow Controller MTL20FD

- مصممة لقياس الغاز منخفض التدفق.

- نسبة الخفض: 50:1 لوحدة التحكم في التدفق الكتلي الرقمي؛ 100:1 لمقياس التدفق الكتلي الرقمي.

- زمن الاستجابة: وحدة التحكم في التدفق الكتلي <0.2 ثانية؛ مقياس التدفق الكتلي <0.1 ثانية

- وحدة تحكم PID مدمجة لتنظيم معدل التدفق

- قياس معدل التدفق الكتلي مباشرة، تعويض درجة الحرارة التلقائي

- شاشة عرض تعمل باللمس

- مناسبة لمختلف خطوط الأنابيب ذات الضغط العالي والمنخفض.

Differential Pressure (DP)-Based Mass Flow Controllers

كيف تعمل: Monitor pressure differences across an internal orifice or laminar flow element; modulate flow with a control valve.

الأفضل لـ Gases, steam, and sometimes liquids in applications requiring broader applicability.

الإيجابيات:

- More robust across environmental variations

- Suitable for multi-fluid applications

السلبيات:

- Less accuracy at very low flows

Differential Pressure Mass Flow Controller MTL20FC

- مصممة لقياس التدفق المنخفض للسائل/الغاز/البخار.

- نسبة الخفض: 50:1 لوحدة التحكم في التدفق الكتلي الرقمي؛ 100:1 لمقياس التدفق الكتلي الرقمي.

- زمن الاستجابة: وحدة التحكم في التدفق الكتلي <0.2 ثانية؛ مقياس التدفق الكتلي <0.1 ثانية

- وحدة تحكم PID مدمجة لتنظيم معدل التدفق

- قياس معدل التدفق الكتلي مباشرة، تعويض درجة الحرارة التلقائي

- شاشة عرض تعمل باللمس

- لا حاجة للتسخين المسبق، ولا يوجد تأخر في الاستجابة أثناء القياس.

Coriolis Mass Flow Controllers

كيف تعمل: Utilize vibrating tubes to measure mass flow directly through the Coriolis effect—a true mass measurement independent of temperature or pressure variations.

الأفضل لـ All fluids—including mixtures and viscous liquids.

الإيجابيات:

- Exceptional accuracy (±0.1–0.2%)

- Measures mass flow, density, and temperature

- Requires minimal recalibration for composition shifts

السلبيات:

- تكلفة أعلى

Coriolis Mass Flow Controller MTL20FE

- MTL20FE measures a wide range of fluids, such as lubricating oil, liquid nitrogen and other high-density fluids can also be accurately measured.

- دقة عالية وتكرار جيد. بالنسبة للسوائل، يمكن أن تصل دقة القياس إلى ± 0.25%؛ وبالنسبة للغازات، يمكن أن تصل دقة القياس إلى ± 0.5%.

- موثوقية وثبات عاليان وقادر على تحمل الظروف البيئية القاسية

Applications of Mass Flow Controllers

Semiconductor and Electronics

Precise gas control is vital in deposition and etching processes (e.g., CVD, PVD).

Laboratories and Research

Essential for exact gas delivery in chemical, physical, or biological experiments.

Biotech and Medical

Used in cell culture control, respiratory gas management, and dosing in medical devices.

Energy & Environmental Monitoring

Crucial for hydrogen fuel cell testing, emissions control, and biogas flow regulation.

Industrial Processing

Integral in welding, metal treatments, and chemical mixing where tight control of gas flow is mandatory.

Mass Flow Controllers remain essential tools across critical industries requiring precise fluid delivery. From thermal MFCs suited for cost-effective gas control, to Coriolis controllers offering top-tier accuracy across all media, and DP MFCs for industrial resilience—each technology brings unique benefits.

If your operation demands compact, ultra-low flow control with fast stabilization, Metlan Instruments’ MFCs are a compelling solution—offering multi-principle versatility, excellent accuracy, and modular designs that seamlessly integrate into high-precision applications.

Here’re some more posts about Mass Flow Controller: