Kategorien

- Thermische Massendurchflussmessgeräte

- Positive Verdrängungsdurchflussmesser

- Mass Flow Meter / Controller

- Coriolis-Durchflussmessgeräte

- Magnetische Durchflussmessgeräte

- Vortex-Durchflussmessgeräte

- Turbinen-Durchflussmessgeräte

- Ultraschall-Gasdurchflussmesser

- Differenzdruck-Durchflussmessgeräte

- Rotameter Durchflussmesser

Bewerbungen

- Öl-Durchflussmessgeräte

- Gasdurchflussmessgeräte

- Dampfdurchflussmessgeräte

- Wasserdurchflussmessgeräte

Others

Dew Point Meters

Excess water vapor in compressed air systems can cause serious problems, including pipeline corrosion, reduced lifespan of pneumatic components, actuator failures, and contamination of the entire system. These issues often lead to unplanned production downtime and significant cost losses. When compressed air cools, its relative humidity rises. Once the temperature drops to the point where relative humidity reaches 100%, water begins to condense into droplets. This temperature is known as the pressure dew point of compressed air.

By continuously monitoring the pressure dew point with a reliable dew point meter, operators can quickly detect drying faults in the compressed air system. This proactive approach helps extend equipment lifespan, improve maintenance efficiency, minimize operational disruptions, and ensure consistent product quality.

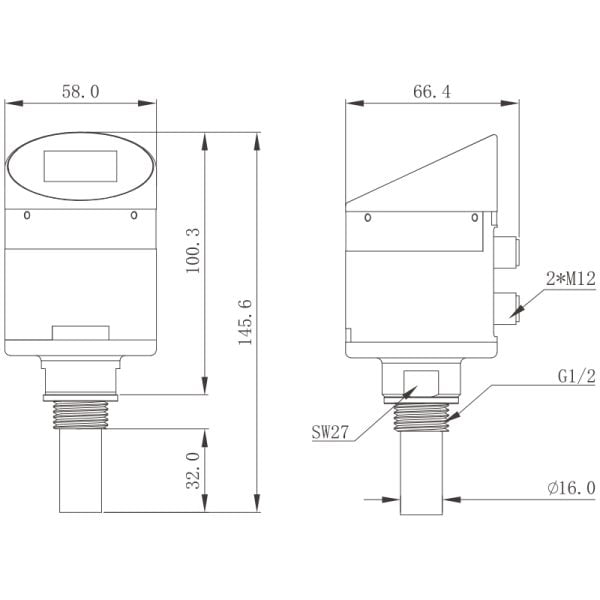

Dew point Meter with Alarm Function M191x

- Display various dew point parameters

- 110 … +60 °C Td measurement range

- Relay alarm output and information display

Accuracy (Dew Point)

± 2 °C Td (+20 … -60 °C Td)

± 3 °C Td (-60 … -100 °C Td)

Measurement Range (Dew Point)

191A: -60 … +60 °C Td

191B: -80 … +20 °C Td

191C: -110 … +20 °C Td

Measurement Range (Temperature)

-40 … +100 °C

Measurement Range (Pressure)

0 … 25 MPa(a)

Portable Dew Point Meter M305x

- Portable, easy to operate

- Display various dew point parameters with graph

- 110 … +60 °C Td measurement range

Accuracy (Dew Point)

± 2 °C Td (+20 … -60 °C Td)

± 3 °C Td (-60 … -100 °C Td)

Measurement Range (Dew Point)

305A: -60 … +60 °C Td

305B: -110 … +20 °C Td

Measurement Range (Temperature)

-40 … +100 °C

Measurement Range (Pressure)

0 … 1.7 MPa(a)

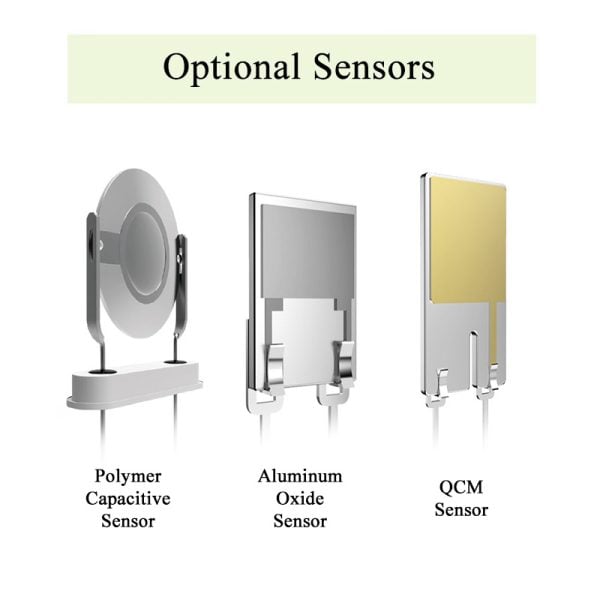

Our Dewpoint Sensor Comparison

| Sensor Model | MT-P | MT-A | MT-Q |

|---|---|---|---|

| Sensor Type | Polymer Capacitive Sensor | Aluminum Oxide Sensor | QCM Sensor |

| Applicable to > -60 °Ctd: Refrigerant Dryer, Desiccant Dryer, Industrial Gas | Yes | ||

| Applicable to -80 … -40 °Ctd: Desiccant Dryer, Nitrogen Generator, Industrial Gas | Yes | ||

| Applicable to -120 … -60 °Ctd: High-purity Industrial Gas | Yes | ||

| Containing Contaminated Particles | Yes | Yes |

What Are the Factors Influencing Dew Point?

The dew point of a gas system does not depend solely on temperature—it is affected by several key factors:

1. Moisture Content (Humidity)

- The more water vapor present in the air, the higher the dew point.

- For example, humid air in tropical climates has a higher dew point compared to dry desert air.

2. Pressure

- Increasing pressure compresses the gas, allowing it to hold less water vapor before reaching saturation.

- This is particularly relevant in compressed air systems: a dew point at 7 bar(g) is different from the same dew point at atmospheric pressure.

3. Temperature

- Although dew point itself is a temperature measurement, ambient temperature fluctuations can influence condensation and sensor performance.

4. Gas Composition

- Pure gases behave differently compared to mixed gases.

- The presence of contaminants or hydrocarbons can alter condensation characteristics and affect dew point readings.

5. System Integrity

- Leaks, inadequate drying, or malfunctioning desiccants can allow more moisture into the system, raising the dew point unexpectedly.