Mechanical flow meters are one of the oldest yet most reliable flow measurement technologies, widely used across oil & gas, chemical, water, and industrial applications. Unlike electronic flow meters that rely on sensors and digital signal processing, mechanical flow meters use physical moving components—gears, rotors, floats, or turbines—to directly measure volumetric flow.

Índice

What Are Mechanical Flow Meters?

A mechanical flow meter is a device that measures flow by converting fluid motion into mechanical movement. As fluid moves through the meter, it drives internal mechanical components, and the movement is translated into volumetric flow.

- Proven, durable, and cost-efficient

- No external power required

- Direct volumetric measurement

- Excellent for viscous liquids

Core Principle:

Mechanical meters directly measure caudal volumétrico by counting physical movement generated by the fluid.

Main Types of Mechanical Flow Meters

Below are the major mechanical flow meter categories—focusing on your requested types with expanded working principles.

Caudalímetros de desplazamiento positivo (PD)

PD flow meters physically trap a known volume of liquid and release it repeatedly. Each cycle corresponds to a fixed volume, allowing extremely accurate volumetric measurement.

PD meters are the most accurate mechanical flow meters and are ideal for viscous fluids such as oil, lubricants, hydraulic fluid, chemicalsy fuel.

Común PD Flow Meter Types

Caudalímetro de engranajes ovalados

Principio de funcionamiento

Two interlocking oval gears rotate inside a precisely machined chamber. As fluid flows through, it forces the gears to rotate. Each rotation displaces a fixed, known volume of liquid. A magnetic or mechanical pickup counts gear rotations → converting displacement into flow rate.

Ventajas

- Extremely high accuracy (±0.2–0.5%)

- Excellent for fluidos de alta viscosidad

- Maintains accuracy despite viscosity changes

- Low sensitivity to flow profile or turbulence

- Caída de presión mínima

- Simple, robust internal structure

Widely used in oil measurement, lubrication systems, and chemical dosing.

Bi-Rotor / Helical Gear PD Flow Meter

Principio de funcionamiento

Two precision-machined helical rotors rotate in opposite directions. As the rotors move, they create sealed cavities that trap fluid and move it axially. Each rotor revolution corresponds to a predictable displaced volume.

Ventajas

- High accuracy (±0.1%–0.5%)

- Very low pulsation

- Wide range of viscosities (fuel → heavy oils)

- High pressure capability

- Smooth flow, minimal vibration

- Excellent long-term stability due to no metal-to-metal contact

Gear Flow Meter

Principio de funcionamiento

Two spur gears mounted in a tight chamber rotate as the liquid flows through. The volume trapped between the gear teeth and meter body is transported around the outer diameter of the gears—each gear rotation equals a known displacement.

Ventajas

- Outstanding low-flow sensitivity

- Ideal for very small flow rates (e.g., MT-GF Low-Flow PD Meter)

- Suitable for thick or thin liquids

- Excellent repeatability

- Compact design

Common in small dosing systems, lubricating oil circuits, and high-precision chemical delivery.

Nutating Disc Flow Meter

The nutating disc is one of the oldest and most widely used PD designs, especially in water metering.

Principio de funcionamiento

- A disc mounted on a central ball or pivot “nutates” (wobbles) inside a chamber.

- As fluid flows, the disc’s wobbling motion displaces fixed fluid volumes through separate compartments.

- Each wobble cycle corresponds to a known volume.

- A mechanical linkage or magnet counts the cycles.

In simple terms:

The disc rocks rather than spins, and each rocking cycle displaces a specific amount of fluid.

Ventajas

- Very robust & proven technology

- Widely used in municipal water meters

- Bajo coste

- Accurate for clean, low- to medium-viscosity liquids

- Works well in domestic and industrial water distribution

Reciprocating Piston Flow Meter

Widely used in fuel dispensing, chemical batching, and lubrication systems.

Principio de funcionamiento

- A piston moves back and forth (reciprocates) inside a cylinder.

- Fluid enters the chamber, pushing the piston in one direction.

- A check valve directs flow during each stroke.

- Every piston stroke displaces a fixed volume.

- Flow is measured by counting the number of strokes.

Ventajas

- Very accurate (±0.2–0.5%)

- Excellent for very high-viscosity liquids (grease, wax, tar)

- Self-priming ability

- Can handle very low flow rates

- High resistance to viscosity swings

Rotary Piston Flow Meter

Rotary piston meters are common in oil meters, LPG dispensers, and industrial batching systems.

Principio de funcionamiento

- A crescent-shaped piston rotates inside an oval or circular chamber.

- As the piston rotates, it traps and transfers fixed liquid volumes.

- Rotary movement is transmitted to a mechanical register or pulse output.

This design is also called a rotary vane o rotary lobe piston depending on geometry.

Ventajas

- Very high accuracy for oils and fuels

- Strong low-flow performance

- Smooth, continuous displacement

- Works for both thin and thick liquids

- Compact and durable design

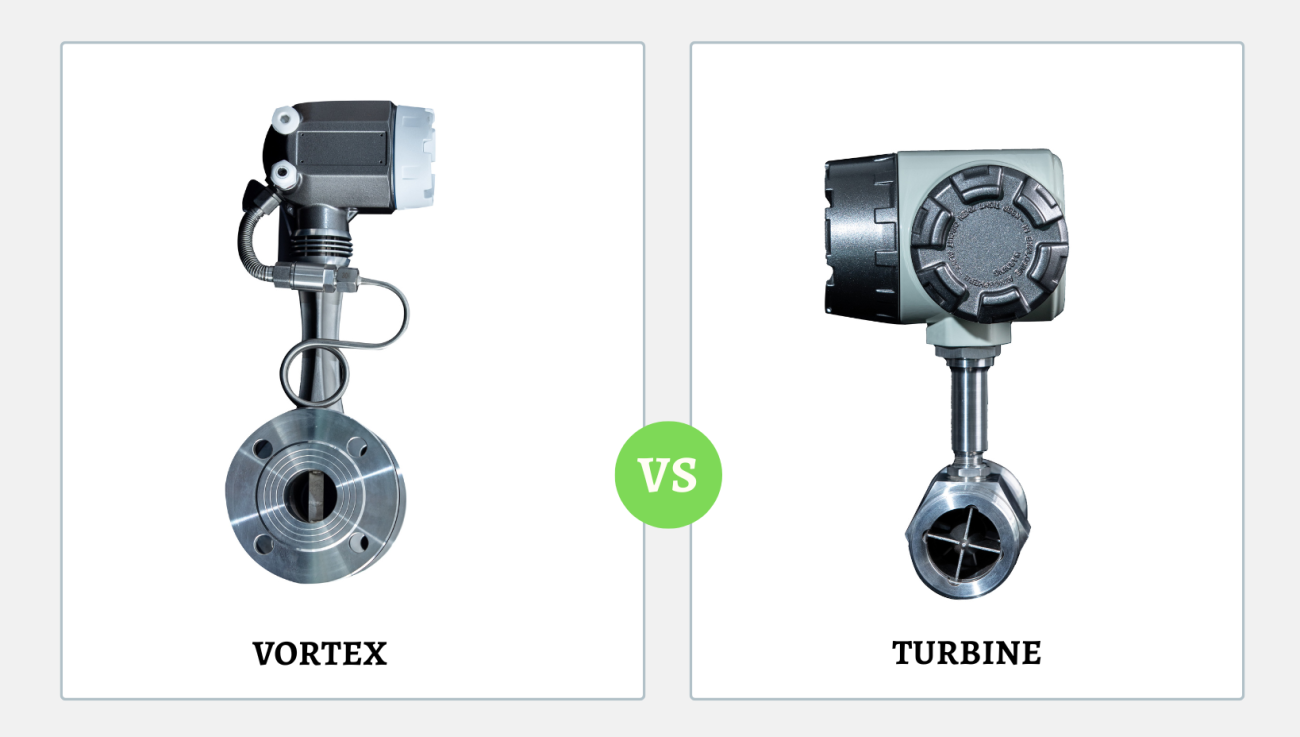

Caudalímetros de turbina

Turbine flow meters are technically mechanical meters because they use a rotating turbine wheel para medir la velocidad del flujo.

Principio de funcionamiento

- Fluid enters the meter and strikes the turbine blades.

- The turbine rotor begins to spin.

- The rotational speed is proportional to fluid velocity.

- Sensors (magnetic, optical, or mechanical) detect each blade passing.

- Pulse frequency → flow rate

- Integration → total flow

This method works best when flow is clean, steady, and has moderate viscosity.

Ventajas

- Alta precisión para light oils and clean liquids

- Tiempo de respuesta rápido

- Suitable for high flow rates

- Good for fuel, water-like liquids, and clean gases

- Lower cost than Coriolis or PD meters

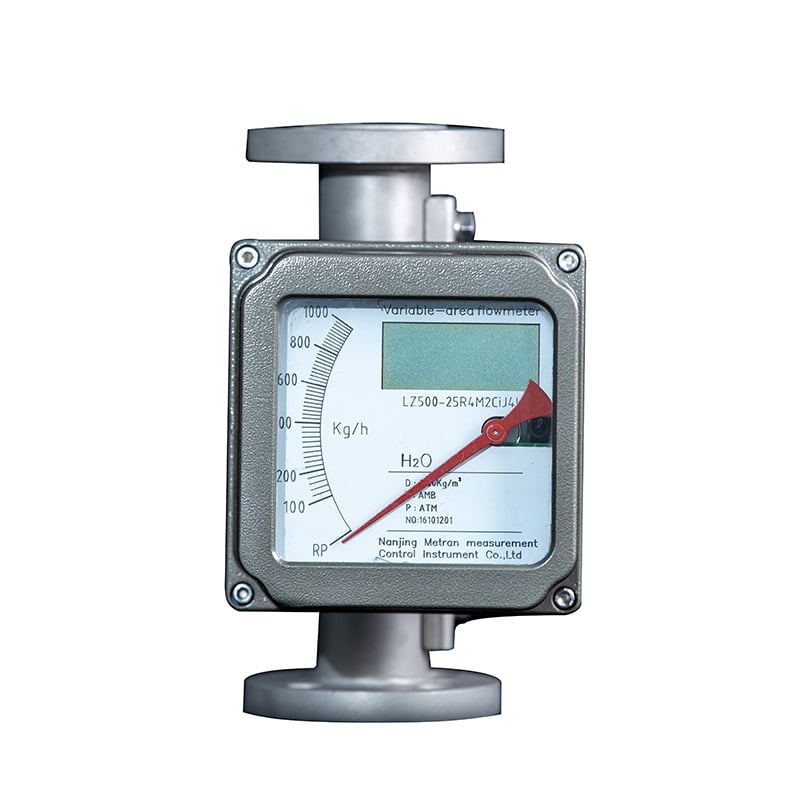

Variable Area (VA) Flow Meters – Rotameters

A variable area meter (commonly a Rotameter) uses a float inside a tapered vertical tube.

Principio de funcionamiento

- The tube widens from bottom to top.

- Flow enters at the bottom, lifting the float.

- Float rises until: upward fluid force = weight of the float

- The float’s height corresponds to a specific flow rate.

- Operators read the flow value from the scale on the tube.

This is a purely mechanical balancing system between gravity and fluid force.

Ventajas

- Ideal for low-pressure and moderate-accuracy applications

- Simple & low-cost

- No power required

- Adecuado para líquidos y gases

- Visual indication, easy to read

Mechanical Flow Meter Mediums

Mechanical meters, especially PD designs, excel in:

High-viscosity liquids

- Hydraulic oil

- Lubrication oils

- Heavy fuel oils (HFO)

- Petróleo

- Resin, grease, syrup

Medium-viscosity liquids

Low-viscosity clean liquids

(Turbine meters perform well here)

- Light fuels

- Clean water

- Disolventes

Mechanical Flow Meters vs Digital Flow Meters

Mechanical Flow Meter Advantages

1. No power needed

Ideal for remote or hazardous areas.

2. Best for viscous fluids

PD meters outperform digital meters on oils and high-viscosity media.

3. High accuracy (especially PD meters)

Up to ±0.1% for premium bi-rotor PD designs.

4. Simple, rugged, long-life design

No electronics → fewer failure points.

5. Cost-effective

Much cheaper than Coriolis or ultrasonic technologies.

6. Less installation sensitivity

PD meters don’t require long straight pipe runs.

7. Excellent low-flow measurement (gear & PD designs)

Where Digital Flow Meters Are Better

- Mass flow measurement

- Gas applications

- Corrosive fluids

- Large pipe sizes

- Extreme precision requirements

- Situations requiring remote monitoring & automation

Mechanical flow meters remain indispensable in oil, fuel, lubrication, and industrial liquid measurement due to their reliability, simplicity, and strong performance with viscous fluids. Each technology offers unique strengths across viscosity, accuracy, cost, and installation requirements.