What Is Fuel?

Fuel is any material that can store potential energy and release it through combustion or another chemical reaction to produce power. It is the essential energy source for engines, power plants, industrial furnaces, and heating systems. Fuels exist in various forms liquid, gaseous, and solid, and each type has different chemical properties, viscosity, and energy density, which influence how it is stored, transported, and measured.

Accurate fuel measurement is crucial because even a small error can lead to significant financial losses, process inefficiencies, or equipment malfunctions. That’s where medidores de caudal de combustível entram em jogo.

Índice

Types of Fuel

Liquid Fuels

Common liquid fuels include diesel, gasoline, kerosene, jet fuel, biodiesel, and heavy oil.

- Diesel: High viscosity, commonly used in industrial engines and generators. Measurement challenges include temperature-dependent density changes and potential air bubbles.

- Gasolina: Low viscosity and volatile, requiring precise sealing and vapor management in flow measurement.

- Kerosene and Jet Fuel: Require high accuracy and cleanliness; contamination can affect performance.

- Biodiesel: More viscous and may contain impurities that affect flow meter stability and calibration.

- Heavy Fuel Oil (HFO): Very viscous and often needs to be heated before measurement. This can complicate installation and calibration.

Gaseous Fuels

Typical gaseous fuels include natural gas, propane, butane, and hydrogen.

- Gás natural: Compressible, and its density changes significantly with temperature and pressure.

- Propane and Butane: Stored under pressure as liquids and converted to gas for combustion, requiring accurate flow control during phase change.

- Hydrogen: Extremely low molecular weight and high diffusivity, which makes measurement sensitive and requires specialized equipment.

Each fuel type poses unique challenges in measurement. Factors like viscosity, temperature, compressibility, and impurities all influence flow meter selection. Therefore, understanding fuel characteristics is the first step in choosing the right medidor de caudal de combustível.

What Is a Fuel Flow Meter?

A medidor de caudal de combustível is an instrument designed to measure the rate and total quantity of fuel flowing through a pipe or system. Depending on the measurement principle, it can measure caudal mássico (the actual amount of fuel) or caudal volumétrico (the volume the fuel occupies).

Fuel flow meters are widely used in:

- Automotive and marine engine testing

- Power generation systems

- Industrial furnaces and burners

- Fuel distribution and transfer systems

- Aerospace and laboratory testing setups

The primary goal of a fuel flow meter is to provide accurate, repeatable measurements regardless of changes in temperature, pressure, or fuel type.

Best Recommended Fuel Flow Meters

Medidores de caudal de deslocamento positivo (PD)

Princípio de funcionamento: PD meters directly measure the fuel volume by trapping fixed quantities between internal moving parts.

Vantagens:

- Precisão muito elevada (±0,1-0,5%)

- Ideal for measuring viscous liquids such as diesel, lubricants, and heavy oils

- Unaffected by changes in flow profile or viscosity Limitações:

- Not suitable for dirty fluids with large particles

- Requires regular maintenance due to mechanical wear

Melhor para: Diesel, heavy oil, and lubricating oil applications.

Medidor de caudal de deslocamento positivo com dois rotores (MT-ABR)

- Alta precisão até ±0,1 %, alta pressão de processo até 110 bar (1595 psi)

- Vida útil extremamente longa, manutenção económica reduzida

- Estável em funcionamento com voz baixa

- Bom desempenho anti-interferência e longa vida útil

- Forte aplicabilidade às alterações de viscosidade

Medidor de caudal de engrenagem de deslocamento positivo de caudal reduzido MT-GF

- Concebida para líquidos de baixo caudal a partir de 0,6 L/H

- Concebida para a medição de fluidos de elevada viscosidade, manuseando meios difíceis como xarope, asfalto fundido e mel com uma precisão fiável

- Medição de alta precisão com exatidão até ±0,5%

- 150:1 wide turndown ratio

Medidores de caudal Coriolis

Princípio de funcionamento: Measures mass flow directly by detecting the Coriolis force generated as fuel flows through vibrating tubes.

Vantagens:

- Measures true mass flow independent of temperature or pressure

- High accuracy (±0.1–0.2%)

- Can measure density and temperature simultaneously Limitações:

- Custo inicial mais elevado

- Sensitive to vibration in large pipelines

Melhor para: Precision fuel dosing, engine testing, and high-value applications involving various liquid or gaseous fuels.

Medidor de caudal mássico Coriolis em forma de W (MTD-ACMW)

- Elevada precisão até ±0,1 %, boa fiabilidade

- Bom desempenho de estabilidade zero e anti-interferência

- Sem partes móveis, sem necessidade de manutenção

Medidor de caudal mássico Coriolis / Controlador MTL20FE

- Concebido para a medição de gás/líquido de baixo caudal.

- Alta precisão, boa repetibilidade. Para líquidos, a exatidão da medição pode atingir ± 0,25%; para gases, a exatidão da medição pode atingir ± 0,5%.

- Rácio de redução: 50:1 para o controlador digital de caudal mássico; 100:1 para o medidor digital de caudal mássico.

- Tempo de resposta: controlador de caudal mássico <0,2s; medidor de caudal mássico <0,1s

- Controlador PID integrado para regular o caudal.

Medidores de caudal mássico térmico

Princípio de funcionamento: Measures gas mass flow based on the heat dissipation rate as fuel gas passes over a heated sensor.

Vantagens:

- Ideal for measuring low-flow or clean gas fuels

- Provides direct mass flow measurement without pressure or temperature compensation Limitações:

- Not suitable for liquids

- Performance can be affected by humidity or particles in the gas

Melhor para: Natural gas, propane, and hydrogen flow measurement.

Medidor de caudal mássico térmico à prova de explosão (MT212x-Ex)

- Classe de proteção contra explosões: Ex db IIC T6 Gb / Ex tb IIIC T80°CDb.

- Adequado para tubos com diâmetros de DN20 a DN1000.

- Rácio de abertura ultra-amplo de 1:2500, a gama de medição é de 0,1 Nm/s a 250 Nm/s.

- Processamento de sinal totalmente digital, maior precisão, estabilidade a longo prazo.

- A estrutura eléctrica totalmente isolada pode filtrar completamente as perturbações do campo.

Medidor de caudal mássico de gás térmico / Controlador (MTL20FD)

- Concebido para a medição de gases de baixo caudal.

- Rácio de redução: 50:1 para o controlador digital de caudal mássico; 100:1 para o medidor digital de caudal mássico.

- Tempo de resposta: controlador de caudal mássico <0,2s; medidor de caudal mássico <0,1s

- Controlador PID integrado para regular o caudal

Medidores de caudal de turbina

Princípio de funcionamento: Uses the rotation speed of a turbine blade to determine the volumetric flow rate.

Vantagens:

- Good accuracy at medium to high flow rates

- Compact and cost-effective Limitações:

- Sensitive to viscosity changes

- Requires stable, clean fuel

Melhor para: Gasoline, kerosene, or aviation fuel under clean conditions.

Medidor de caudal de turbina para líquidos de alta precisão (LWGYMT-AJWL)

- Elevada exatidão até ±0,2 %, com boa repetibilidade.

- Rácio de redução de 1:20.

- Estrutura economizadora de espaço com diâmetro mínimo de furo DN0,5.

- As cores e o aspeto podem ser personalizados a pedido

Medidores de caudal ultra-sónicos

Princípio de funcionamento: Measures flow velocity using the time difference between transmitted and received ultrasonic pulses.

Vantagens:

- No moving parts, minimal maintenance

- Suitable for both liquid and gas fuels

- Can be installed non-intrusively (clamp-on type) Limitações:

- Accuracy depends on installation and pipe conditions

- Not ideal for very viscous or aerated fuels

Melhor para: Clean liquid fuels, pipeline monitoring, and large-diameter flow measurement.

Medidor de caudal de gás ultrassónico de alta precisão (MTS-LYNSB)

- Alta precisão para gás até ±0,5%

- Sem peças móveis, sem perda de pressão, sem obstruções na linha

- Sem lubrificação ou manutenção periódica

- A medição não é afetada pelas propriedades do gás

- Rácio de abertura ampla de 100:1

- Capacidade bidirecional

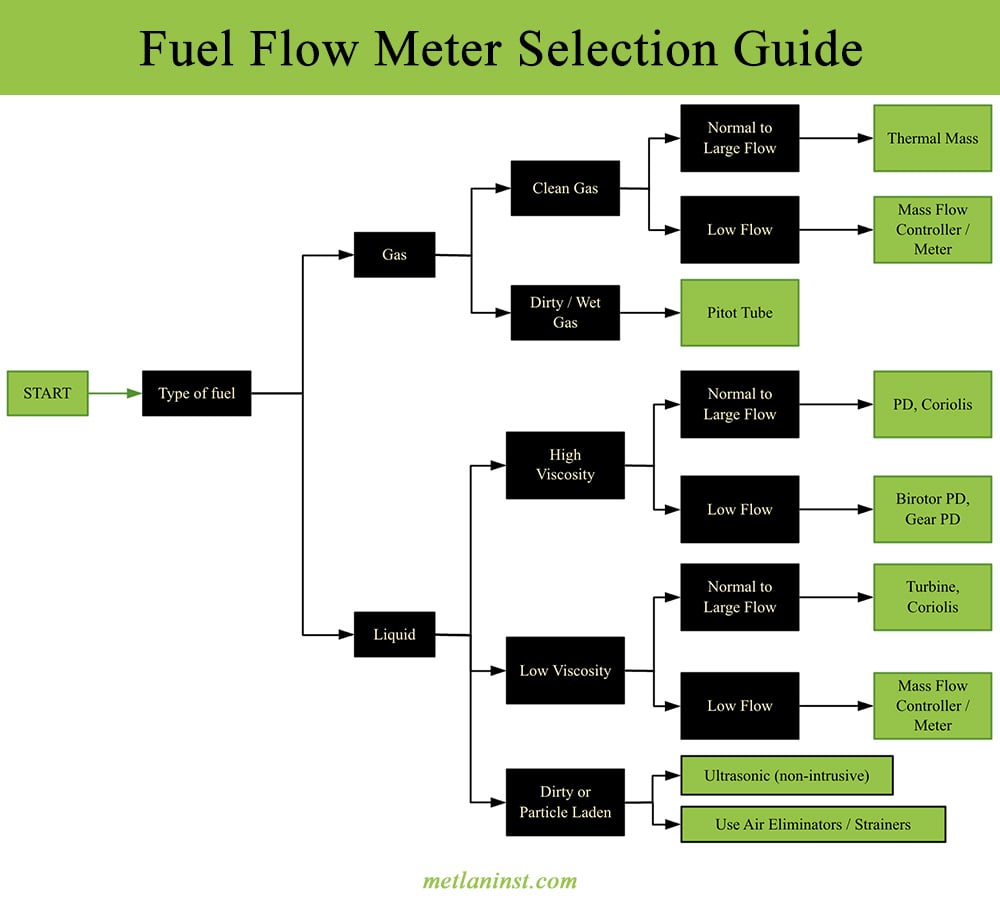

How to Choose the Right Fuel Flow Meter

Selecting the proper fuel flow meter depends on the type of fuel, flow conditions, accuracy requirements, and installation environment. Below are key factors to consider:

Fuel Type and Properties

Identify whether you are measuring liquid or gas fuel, its viscosity, density, and temperature range.

- For viscous liquids (diesel, oil) → choose Deslocamento positivo ou Coriolis meters.

- For light liquids (gasoline, kerosene) → Turbina ou Coriolis meters work well.

- For gas fuels (natural gas, hydrogen) → Massa térmica ou Ultrassónico meters are preferred.

Measurement Range and Accuracy

Define the required flow range and precision level.

- Laboratory and testing setups require ±0.2% or better accuracy (Coriolis, PD).

- Industrial transfer applications may allow ±1% accuracy (Thermal Mass, Turbine).

Pressure and Temperature Conditions

High-pressure or high-temperature systems require robust sensors and materials resistant to corrosion and thermal stress. Stainless steel or specialized alloys are typically used.

Maintenance and Installation

For remote or continuous operations, select meters with manutenção reduzida e digital output compatibility (e.g., 4–20 mA, RS485, or Modbus).

Clamp-on ultrasonic meters can be ideal when non-intrusive installation is required.

Cost and Lifecycle

Consider total ownership cost, not just the purchase price. A higher initial investment in a Coriolis or PD meter may yield long-term savings through accuracy, reduced downtime, and energy efficiency.

Fuel Flow Meter Selection Guide

| Selection Factor | Key Considerations | Recommended Flow Meter Types | Typical Fuel Examples |

|---|---|---|---|

| Fuel Phase | Determine whether the fuel is liquid ou gas. | – Liquid: Positive Displacement, Coriolis, Turbine – Gas: Thermal Mass, Ultrasonic | Liquid fuels: Diesel, Gasoline, Jet Fuel Gas fuels: Natural Gas, Propane, Hydrogen |

| Viscosidade | High-viscosity fuels require meters that handle thick, slow-moving fluids. | – High viscosity: PD, Coriolis – Low viscosity: Turbine, Coriolis | Diesel, Heavy Oil → PD/Coriolis Gasoline, Kerosene → Turbine/Coriolis |

| Accuracy Requirement | Define precision needed for your process (e.g., testing vs. monitoring). | – High accuracy (±0.2%): Coriolis, PD – Medium (±0.5%–1%): Turbine | Engine testing → Coriolis, PD, Fuel transfer → PD/Turbine |

| Cleanliness / Particle Content | Dirty or particle-laden fuels can cause mechanical wear. | – Clean fuels: Turbine, Coriolis – Dirty fuels: Ultrasonic (non-intrusive) | Biodiesel (filtered) → PD Heavy oil with impurities → Ultrasonic |

| Budget / Lifecycle Cost | Consider total cost of ownership (accuracy, maintenance, calibration). | – Low-cost: Turbine – Mid-range: PD – Premium: Coriolis | Cost-sensitive sites → Turbine Long-term precision → Coriolis |

Applications of Fuel Flow Meters

Fuel flow meters are essential in multiple sectors:

- Automotive and Marine Engines: Real-time fuel consumption monitoring and efficiency analysis.

- Aviation: Precise jet fuel measurement for safety and performance.

- Power Generation: Monitoring fuel supply to turbines and boilers.

- Oil & Gas Industry: Custody transfer, blending, and leak detection.

- Laboratory and Research: Calibration, performance testing, and emission studies.

Accurate measurement not only improves operational efficiency but also helps meet environmental and safety regulations.

A medidor de caudal de combustível is more than just a measuring device—it is a critical component that ensures energy efficiency, process control, and cost management. Whether dealing with diesel, gasoline, natural gas, or hydrogen, selecting the right flow meter type can significantly impact performance and reliability.