Vortex Flow Meters

Working Principles of Vortex Flow Meters

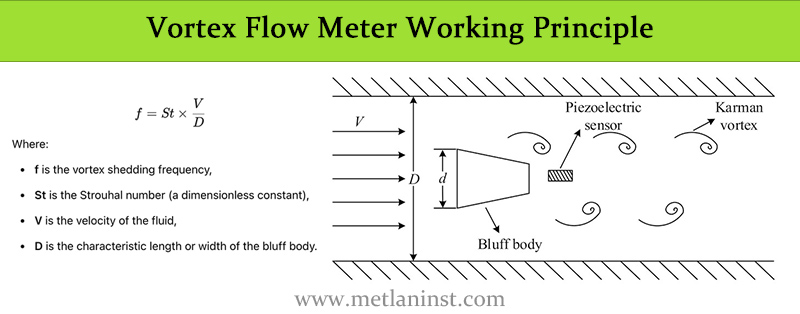

A vortex flow meter is a type of flow measurement instrument that measures the volumetric flow rate of fluids, such as liquids, gases, and steam, by detecting vortices shed from a bluff body inserted into the flow stream. The operation of a vortex flow meter is based on the phenomenon known as the von Kármán effect. When a fluid flows past a bluff body—a non-streamlined object—vortices are generated alternately on either side of the body. These vortices form a repeating pattern known as a Kármán vortex street. The frequency at which these vortices are shed is directly proportional to the velocity of the fluid flow.

Steam Vortex Flow Meter Anti-vibration (LUGBMT-VS)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Steam/Gas: 3.5 to 20347.2 m³/h

Medium Temperature Range

Standard: –40 to +160 °C

High/low temperature (option): –180 to +350 °C

Max. Process Pressure

63 bar (913.74 psi)

Vortex Flow Meters (LUGBMT-100)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Liquid: 0.8 to 3500 m³/h

Steam, gas: 5 to 18000 m³/h

Medium Temperature Range

Standard: –40 to +260 °C (–40 to +480 °F)

High/low temperature (option): –200 to +400 °C (–328 to +750 °F)

Max. Process Pressure

100 bar (1450.38 psi)

Vortex Flow Meters with Temperature and Pressure Compensation (LUGBMT-C)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Liquid: 0.8 to 3500 m³/h

Steam, gas: 5 to 18000 m³/h

Medium Temperature Range

Standard: –40 to +260 °C (–40 to +480 °F)

High/low temperature (option): –200 to +350 °C (–328 to +660 °F)

Max. Process Pressure

100 bar (1450.38 psi)

Vortex Flow Meter for High Pressure (LUGBMT-P)

Accuracy

Liquid/Gas/Steam: ±1 %

Measuring Range

Liquid: 0.8 to 3500 m³/h

Steam, gas: 5 to 18000 m³/h

Medium Temperature Range

Standard: –40 to +260 °C (–40 to +480 °F)

High/low temperature (option): –200 to +350 °C (–328 to +660 °F)

Max. Process Pressure

250 bar (3625.95 psi)

Benefits of Vortex Flow Meters

Versatility

Vortex flow meters can measure the flow of liquids, gases, and steam, making them versatile for various applications.High Accuracy and Repeatability

These meters provide accurate and repeatable flow measurements with minimal drift over time, making them reliable for critical processes.Low Maintenance

With no moving parts, vortex flow meters require less maintenance compared to other flow meters like turbine or positive displacement meters. This also reduces the risk of wear and tear, increasing their lifespan.Wide Range of Flow Rates

Vortex flow meters are capable of measuring a wide range of flow rates, from low to high velocities, which makes them suitable for different industrial requirements.Unaffected by Fluid Properties

The measurement accuracy of vortex flow meters is not significantly affected by changes in fluid properties such as viscosity, density, or temperature, making them robust for varying process conditions.Suitable for High-Temperature and High-Pressure Applications

Many vortex flow meters are designed to withstand high temperatures and pressures, making them ideal for applications involving steam and hot fluids.

Types of Vortex Flow Meters

Inline Vortex Flow Meters

These are the most common type of vortex flow meters, where the meter is installed directly into the pipeline. The bluff body and sensors are integrated into the flow meter body, which is sized to fit a specific pipeline diameter. They are suitable for precise flow measurements in both small and large pipes.Insertion Vortex Flow Meters

Insertion vortex flow meters have a probe design, where the bluff body and sensor are inserted into the pipeline through a small opening. These meters are typically used for large pipelines where installing an inline meter would be impractical or expensive. They are cost-effective and suitable for measuring flow in large pipes with a wide range of diameters.Clamp-on Vortex Flow Meters

These are non-intrusive vortex flow meters that are clamped onto the outside of the pipe. They use ultrasonic sensors to detect vortex shedding and are ideal for applications where the flow cannot be interrupted or where the pipe material cannot be penetrated. They are commonly used in temporary flow measurement setups or when retrofitting existing systems.

Applications of Vortex Flow Meters

- Oil and Gas Industry

- Chemical and Petrochemical Industry

- Water and Wastewater Management

- HVAC and Building Automation

- Power Generation

- Pharmaceutical Industry

Gas Flow Meters | Pitot Tube Flow Meters | Flow Meter Controllers | Coriolis Flow Meters | Ultrasonic Gas Flow Meters | Magnetic Flow Meters | Turbine Flow Meters | Thermal Mass Flow Meters | Differential Pressure Flow Meters