Liquefied Petroleum Gas (LPG) is a versatile and widely used fuel across residential, commercial, and industrial sectors. From home heating to vehicle fueling, accurate LPG flow meter measurement is crucial not only for operational efficiency but also for regulatory compliance and billing transparency.

What Is LPG?

Liquefied Petroleum Gas (LPG) refers to propane, butane, or a mixture of both, which is stored under moderate pressure as a liquid and vaporizes upon release. It is sourced from natural gas processing and petroleum refining.

Because LPG exists in both liquid and gas phases, selecting the right flow meter depends on the phase in which it is being measured and the operating conditions of the application.

Key Characteristics of LPG for Flow Measurement

- Phase Sensitivity: LPG behaves differently in gas and liquid form. Measurement must account for phase stability to avoid errors.

- Volume vs. Mass Variability: The volume of LPG changes significantly with temperature, while its mass remains constant. This makes mass flow measurement preferable, especially in commercial transactions.

- Compressibility: As a gas, LPG is highly compressible, making volume-based readings less accurate unless compensated.

- Flammability: All equipment must meet explosion-proof standards (ATEX, IECEx).

- Variable Composition: Changes in the propane/butane ratio affect density and flow characteristics.

Recommended LPG Flow Meter

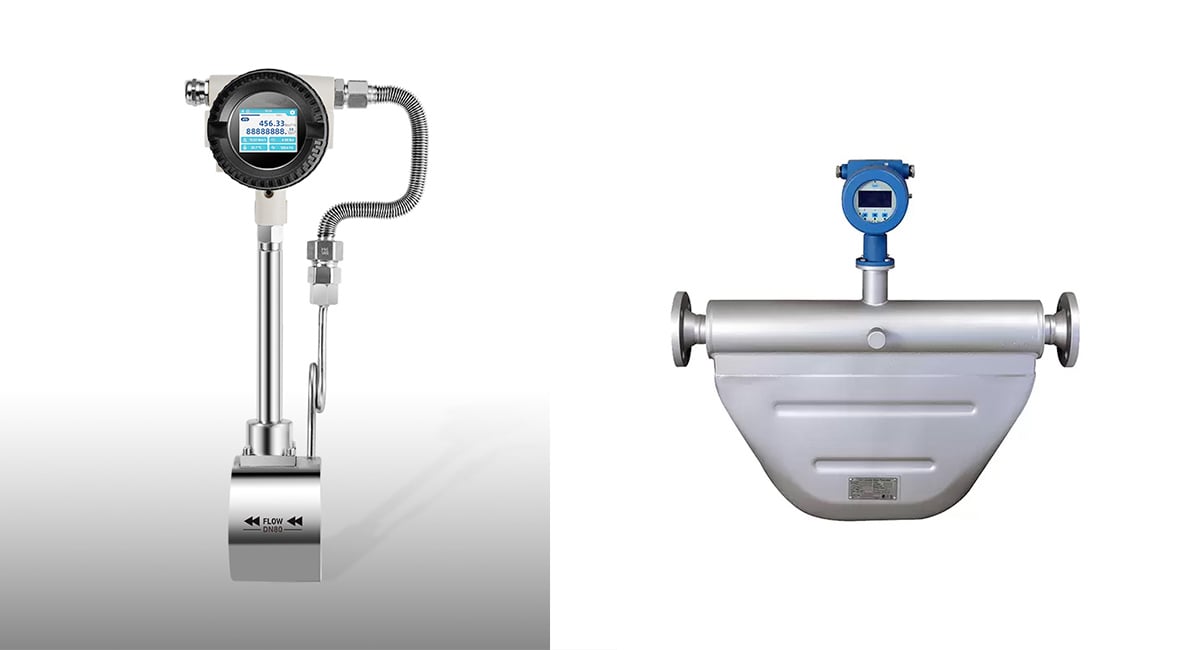

1. Coriolis Mass Flow Meters

Najlepsze dla: Liquid and gas phase LPG; custody transfer; billing applications

Zalety:

- Środki przepływ masowy bezpośrednio, unaffected by temperature or pressure.

- Provides real-time density and temperature readings.

- Odpowiedni dla OIML R117 oraz MID-certified billing systems.

- Excellent long-term stability and repeatability.

Ograniczenia:

- Higher initial cost than other technologies.

2. Przepływomierze wyporowe (PD)

Najlepsze dla: Liquid LPG in bottling or small-scale transfer systems

Zalety:

- Good accuracy and repeatability in clean, steady flow.

- Cost-effective for smaller operations.

- Doesn’t require power (mechanical models).

Ograniczenia:

- Not suitable for gas phase.

- Środki objętość, not mass — requires temperature and density compensation in billing applications.

3. Przepływomierze turbinowe

Najlepsze dla: Clean liquid LPG in process monitoring (non-billing use)

Zalety:

- Moderate cost and decent accuracy under stable flow.

Ograniczenia:

- Not ideal for custody transfer or dynamic temperature conditions.

- Środki objętość, highly sensitive to flow profile and viscosity.

- Requires long straight pipe sections before and after installation.

4. Thermal Mass Flow Meters

Najlepsze dla: Gaseous LPG; leak detection; process control

Zalety:

- Direct mass flow measurement of gases.

- No moving parts; minimal maintenance.

- Good for low-flow and precise control applications.

Ograniczenia:

- Accuracy affected by gas composition changes (e.g., propane vs. butane mix).

- Only suitable for gas phase.

Why Mass Flow Matters for LPG Transactions

A key point is that billing by mass is fairer and more accurate than billing by volume, especially in regions with large temperature swings. For example, 1 liter of LPG at 0 °C contains significantly more energy than 1 liter at 40 °C.

Mass flow meters prevent discrepancies, ensure billing transparency, and meet evolving regulations. In many regions, LPG dispensers are being retrofitted with Coriolis meters to comply with new laws and improve customer trust.

How to Choose the Right LPG Flow Meter

Step 1: Identify the LPG Phase

- Liquid phase: Coriolis, PD, or turbine meters.

- Gas phase: Coriolis or thermal mass meters.

Step 2: Know Your Accuracy Requirements

- For custody transfer lub rozliczenie, select a mass flow meter, especially Przepływomierz masowy Coriolisa.

- For internal monitoring, PD or turbine meters may suffice.

Step 3: Consider Temperature and Pressure Conditions

- Wide temperature fluctuations? Choose przepływ masowy to avoid compensation errors.

Step 4: Verify Compliance & Certification

- Look for ATEX/IECEx oraz OIML/MID marks for regulated environments.

Step 5: Account for Maintenance and Integration

- Fewer moving parts = lower maintenance (e.g., Coriolis, thermal).

- Opt for meters with Modbus, HART, or Ethernet protocols for SCADA systems.

The right LPG flow meter depends on your measurement phase, regulatory needs, and operational environment. As Krohne’s experience shows, mass flow meters like Coriolis types provide the most accurate, reliable, and regulation-ready solution—especially in custody transfer and LPG dispensing applications.

For process monitoring or internal use, PD and turbine meters still have value but come with caveats—especially where temperature variation or billing fairness is a concern.

Need Help Choosing an LPG Flow Meter?

We provide expert guidance and industrial-grade flow metering solutions, including:

- Przepływomierze masowe Coriolisa for LPG dispensers and terminals

- Mierniki PD for bottling plants

- Thermal mass meters for gas-phase monitoring

Skontaktuj się z nami today to get the right meter for your application.