As the world transitions toward cleaner energy sources, hydrogen has emerged as a key player in sustainable development. From fuel cells and industrial manufacturing to the chemical and energy sectors, hydrogen’s versatility makes it an increasingly valuable commodity. However, measuring hydrogen flow accurately presents unique technical challenges due to its physical properties and the demanding environments in which it is used.

Índice

Understanding Hydrogen and Its Industrial Applications

Characteristics of Hydrogen

Hydrogen (H₂) is the lightest and smallest molecule in the universe, with unique physical characteristics that both enable and complicate its use in industry.

| Property | Descrição |

|---|---|

| Molecular Weight | 2.016 g/mol (the lightest gas) |

| Densidade | 0.0899 kg/m³ at 0°C and 1 atm |

| Flammability Range | 4–75% in air (highly flammable) |

| Diffusivity | Extremely high; leaks easily through small gaps |

| Thermal Conductivity | Very high compared to other gases |

| Typical State | Gas at standard temperature and pressure; can be liquefied at -253°C |

Because hydrogen molecules are so small and light, leakage, diffusion, and compression issues are common in pipelines and storage systems. These unique traits make flow measurement of hydrogen far more complex than other gas flow measurement.

Main Industrial Applications of Hydrogen

Hydrogen plays a critical role across multiple industries, including:

- Hydrogen fuel cells – Used in electric vehicles (FCEVs), backup power systems, and portable energy solutions.

- Oil refining – Hydrogen is essential for desulfurization and hydrocracking processes.

- Ammonia and fertilizer production – Hydrogen combines with nitrogen to form ammonia (NH₃).

- Chemical manufacturing – Used as a reducing agent in metal refining and in producing methanol or other chemicals.

- Semiconductor and electronics industries – Employed as a carrier or process gas in controlled environments.

- Hydrogen energy infrastructure – Flow measurement in storage, transport, and refueling systems.

In all these cases, accurate and reliable hydrogen flow measurement is crucial for process efficiency, safety, and regulatory compliance.

What Is a Hydrogen Flow Meter?

A hydrogen flow meter is an instrument used to measure the flow rate or total quantity of hydrogen gas (or liquid hydrogen) passing through a pipeline or process system. Depending on the application, the flow meter may measure:

- Caudal mássico (e.g., in kg/h or g/s)

- Volumetric flow rate (e.g., in m³/h or L/min)

- Standardized flow rate (e.g., in Nm³/h, under specific temperature and pressure conditions)

Hydrogen flow meters are used in both industrial processes (for dosing, reaction control, or leak detection) and energy applications (such as hydrogen fueling stations).

Why Accurate Hydrogen Flow Measurement Matters

- Process Safety Hydrogen is highly flammable and explosive in air. Accurate measurement ensures controlled supply and minimizes leak or overpressure risks.

- Efficiency and Cost Control In hydrogen production, distribution, or utilization systems, flow measurement is essential to manage efficiency, energy consumption, and material costs.

- Regulatory Compliance and Custody Transfer For commercial hydrogen transactions (e.g., hydrogen refueling stations), precise metering ensures fair trade and regulatory compliance.

- System Optimization Flow data helps optimize production, purification, and consumption processes in hydrogen systems.

Challenges in Measuring Hydrogen Flow

Measuring hydrogen is technically challenging due to its unique molecular and thermal properties:

| Desafio | Explanation |

|---|---|

| Low Density | Hydrogen’s very low density makes it difficult for volumetric meters to detect flow accurately. |

| High Velocity and Compressibility | Hydrogen flows quickly even at low mass rates, requiring high-speed sensing technology. |

| Leakage Tendency | Hydrogen easily escapes through seals and joints, which can affect measurement and safety. |

| Wide Range of Conditions | Hydrogen systems may operate under very high pressures (up to 700 bar in refueling stations) or cryogenic temperatures (for liquid H₂). |

| Explosion Risk | Hydrogen’s flammability requires intrinsically safe and explosion-proof equipment. |

These challenges mean that not every flow meter type is suitable for hydrogen. Selection must consider sensitivity, accuracy, pressure rating, materials, and safety certifications.

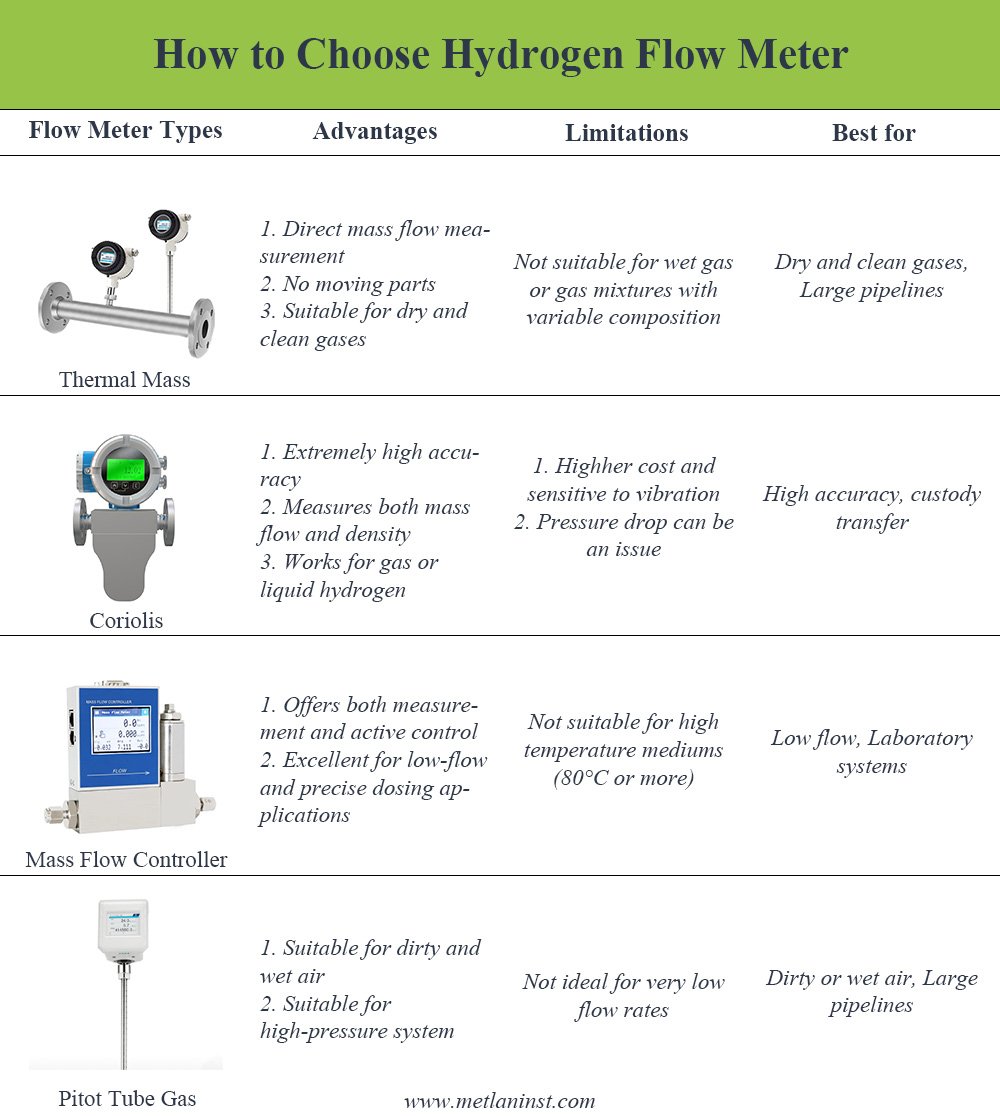

Recommended Types of Hydrogen Flow Meter

Several flow meter technologies can be used for hydrogen, but each has specific advantages and limitations depending on the phase (gas or liquid), flow rangee operating environment.

1. Medidores de caudal mássico térmico

Princípio de funcionamento:

Thermal mass flow meters measure hydrogen gas flow by detecting the amount of heat carried away from a heated sensor element as the gas passes through it.

Vantagens:

- Direct mass flow measurement (no need for temperature or pressure compensation)

- No moving parts → minimal maintenance

- Adequado para dry and clean gases

Limitações:

- Não adequado para wet gas or gas mixtures with variable composition

- Accuracy can be affected by changes in gas thermal conductivity

Best Applications:

- Hydrogen leak detection systems

- Gas blending and purity monitoring

- Laboratory and process control for hydrogen gas

Metlan Instruments Thermal Mass Flow Meters

- Classe de proteção contra explosões: Ex db IIC T6 Gb / Ex tb IIIC T80°CDb.

- Ultra-wide 1:2500 turndown ratio, the measuring range is from 0.1 Nm/s to 250 Nm/s.

- Processamento de sinal totalmente digital, maior precisão, estabilidade a longo prazo.

2. Medidores de caudal mássico Coriolis

Princípio de funcionamento:

Coriolis flow meters measure fluxo de massa diretamente by detecting the phase shift in vibrating tubes as hydrogen flows through them.

Vantagens:

- Extremely high accuracy (±0.1–0.2%)

- Measures both mass flow and density

- Works for gas or liquid hydrogen

- Immune to changes in pressure, temperature, or gas composition

Limitações:

- Higher cost and sensitive to vibration

- Pressure drop can be an issue in gas systems

- Requires careful installation and calibration

Best Applications:

- Hydrogen fueling stations (custody transfer)

- Hydrogen production and pipeline monitoring

- Chemical and refinery hydrogen systems

Coriolis flow meters are often the preferred choice for high-accuracy hydrogen measurement due to their direct mass flow capability.

3. Gas Mass Flow Controllers (MFCs)

Princípio de funcionamento:

MFCs integrate a thermal mass flow sensor, control valve, and electronic feedback loop to measure and regulate hydrogen gas flow precisely.

Vantagens:

- Offers both measurement and active control

- Excellent for low-flow and precise dosing applications

- Fast response and easy integration into process systems

Limitações:

- Typically limited to low-pressure and low-flow laboratory or pilot systems

- Sensitive to contamination or moisture

Best Applications:

- Laboratory hydrogen experiments

- Semiconductor and fuel cell research

- Controlled gas delivery systems

Metlan Instruments Mass Flow Controllers

- Designed for low flow applications with laboratory level measurement accuracy.

- Avaialable to measure high viscosity fluid and high density gas.

- Rácio de redução: 50:1 para o controlador de caudal mássico; 100:1 para o medidor de caudal mássico.

- Alta estabilidade, derivação tubular para evitar bloqueios.

MFCs are ideal when precision control is required, such as in hydrogen blending or coating processes.

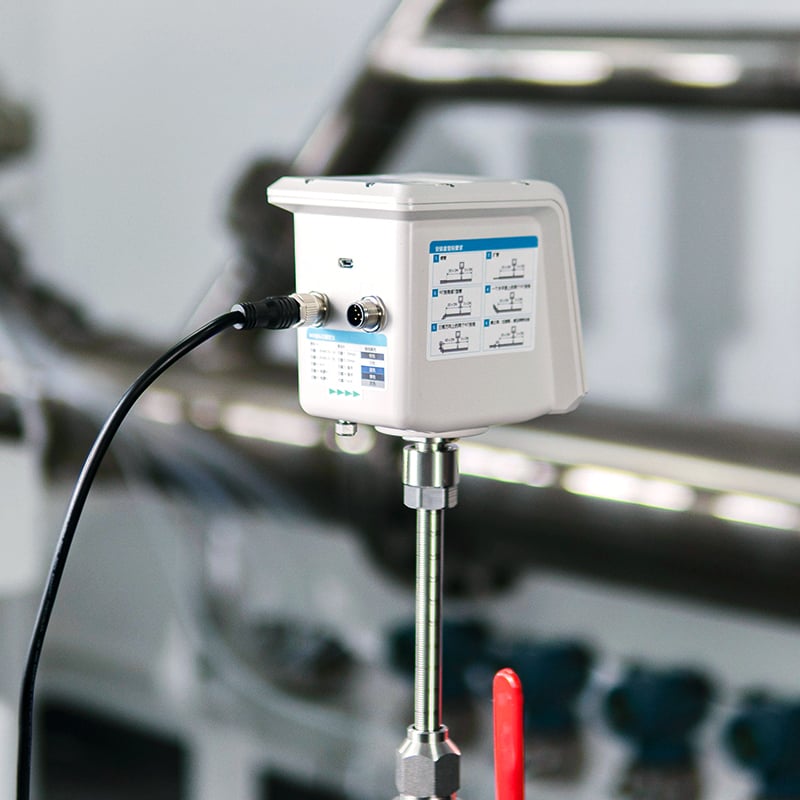

4. Pitot Tube Gas Flow Meters

Princípio de funcionamento:

Pitot tube meters measure the velocity pressure of hydrogen gas in a pipeline using differential pressure sensors.

Vantagens:

- Suitable for dirty and wet air

- Works well in large pipelines with steady flow

- Adequado para high-pressure hydrogen systems

Limitações:

- Not ideal for very low flow rates or pulsating flow

Best Applications:

- Industrial gas supply lines

- Large hydrogen distribution systems

Medidor de caudal de gás com tubo Pitot da Metlan Instruments

- Aplicável à medição de ar sujo e húmido

- A auto-calibração em linha reduz o desvio de dados

- alta sensibilidade, o limite inferior é de 5 Nm/s

- Rácio de abertura ampla de 1:60

- Medição de caudal bidirecional

While not as precise as Coriolis or thermal types, Pitot tubes are useful for high-flow, high-pressure industrial pipelines.

How to Choose the Right Hydrogen Flow Meter

Selecting the right hydrogen flow meter depends on several technical and environmental factors. Below are the key criteria to consider:

Define the Hydrogen Form and Flow Range

- For low-flow, low-pressure gas, use a mass flow controller (controlador térmico de caudal mássico).

- For alta pressão applications (e.g., fueling stations), use a Thermal Mass flow meter.

- For grandes condutas with stable flow, Pitot tubes may be cost-effective.

- For cryogenic or liquid hydrogen, choose a Coriolis flow meter rated for low temperatures.

Hydrogen systems can range from ambient to over 700 bar, and temperatures from -253°C (liquid) para 400°C (industrial gas).

Make sure the flow meter:

- Has suitable pressure and temperature ratings

- Utilizações leak-tight seals and compatible materials (e.g., stainless steel, Hastelloy)

Material Compatibility and Safety

Hydrogen can cause hydrogen embrittlement in certain metals, leading to cracks or leaks. Choose meters with:

- 316L stainless steel or nickel alloys for high-pressure gas

- PTFE or PFA linings for corrosive gas mixtures

- ATEX or IECEx certifications for explosive environments

Measurement Accuracy and Range

Accuracy requirements vary by application:

- Fueling and custody transfer → ±0.5% or better (Coriolis recommended)

- Process monitoring → ±1–2% (Thermal or Pitot acceptable)

- Laboratory control → ±0.5% (MFC ideal)

Integration and Output Options

Modern hydrogen flow meters should support digital communication protocols like:

- 4–20 mA analog output

- RS485 / Modbus RTU

- HART / Profibus / EtherNet/IP

This ensures easy integration into SCADA or PLC systems for process automation.

Hydrogen, as one of the most promising clean energy carriers, presents both opportunities and challenges for accurate flow measurement. Due to its low density, high velocity, and flammability, not every flow meter can handle hydrogen safely or accurately.

When choosing a hydrogen flow meter, always consider the flow range, pressure, temperature, material compatibility, and safety certification to ensure long-term reliability and accuracy.

About Metlan Instruments Hydrogen Flow Meters

Em Metlan Instruments, we specialize in advanced flow measurement technologies for gases and liquids — including hydrogen. Our product range features Medidores de caudal mássico térmico, Medidores de caudal Coriolise Gas Mass Flow Controllers, all engineered for precision, safety, and stability under demanding industrial conditions.

Metlan’s hydrogen flow meters are built with high-grade stainless steel, leak-proof designe intrinsically safe certifications, making them ideal for hydrogen production, storage, and fuel applications. Whether you need low-flow laboratory control ou high-pressure industrial measurement, Metlan Instruments provides reliable and accurate hydrogen flow solutions to power the clean energy future.