Argon is one of the most widely used noble gases in both industrial and laboratory applications. From shielding gas in welding processes to protective atmospheres in the semiconductor and pharmaceutical industries, argon plays a crucial role in ensuring quality, efficiency, and safety. However, to use argon effectively and avoid unnecessary costs, precise monitoring and control of its flow are essential. This is where argon flow meters ins Spiel kommen.

Inhaltsübersicht

Characteristics of Argon and Its Applications

Key Properties of Argon

- Trägheit: Argon is a chemically inert noble gas. It does not readily react with other elements or compounds under normal conditions.

- Non-flammable: Argon is non-flammable and provides a stable atmosphere that reduces oxidation and other unwanted chemical reactions.

- Dichte: Argon is denser than air, which makes it an effective shielding gas that can displace oxygen in localized areas.

- Colorless and odorless: Like other noble gases, argon has no color, odor, or taste, making it difficult to detect without proper instrumentation.

Applications of Argon

Argon’s unique properties make it indispensable across a wide range of industries:

- Welding and Metal Fabrication

- Used as a shielding gas in gas tungsten arc welding (GTAW/TIG) and gas metal arc welding (GMAW/MIG).

- Prevents oxidation and contamination of the weld zone.

- Semiconductor Manufacturing

- Provides an ultra-pure, inert atmosphere during the production of semiconductors and microelectronics.

- Pharmaceutical and Food Industry

- Used to displace oxygen in packaging, thereby extending product shelf life and preventing degradation.

- Lighting and Electronics

- Fills incandescent and fluorescent light bulbs to protect filaments from oxidation.

- Used in plasma globes and other electronic devices.

- Laboratory and Research Applications

- Provides inert atmospheres for sensitive experiments and analytical instruments like mass spectrometers and gas chromatographs.

What Is an Argon Flow Meter?

An argon flow meter is an instrument designed to measure and monitor the flow rate of argon gas through a system. Flow rates are typically expressed in standard liters per minute (SLPM) or cubic feet per hour (CFH), depending on the industry standard.

Why Measuring Argon Is Important

- Process Quality: In welding, incorrect argon flow can lead to porous welds, contamination, or wasted shielding gas.

- Kosteneffizienz: Argon is relatively expensive. Accurate flow measurement helps minimize waste and reduce operating costs.

- Sicherheit: Since argon is colorless and odorless, leaks or excessive discharges may pose asphyxiation risks in enclosed environments. Monitoring ensures safe operation.

- Compliance: Many industries require precise control of gas flow to meet quality and safety standards.

Recommended Argon Flow Meters

When it comes to argon measurement, not all flow meter technologies are equally effective. The following four types are the most suitable for handling argon gas across different industries and applications:

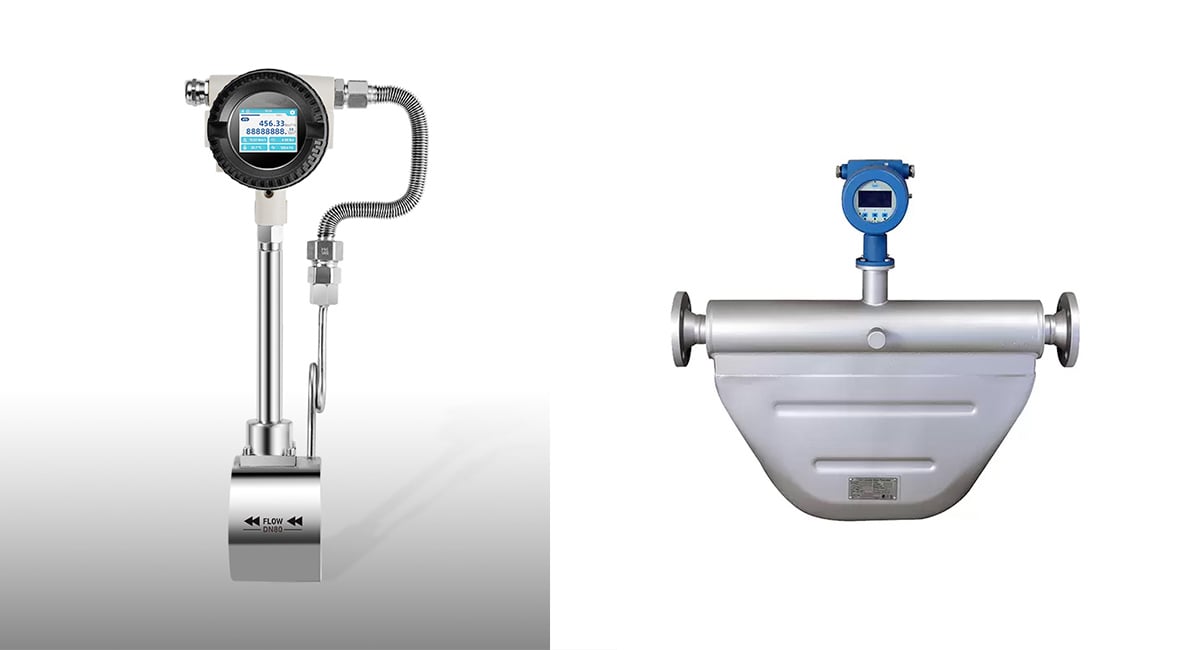

Thermische Massendurchflussmessgeräte

- How they work: Measure the heat transfer between a heated sensor and the argon gas flow.

- Why they’re suitable: They provide direkte Massendurchflussmessung without the need for temperature or pressure compensation, making them highly accurate and reliable for argon.

- Anwendungen: Laboratories, semiconductor manufacturing, and industrial processes where precise argon consumption must be monitored and controlled.

- Explosionsschutzklasse: Ex db IIC T6 Gb / Ex tb IIIC T80°CDb.

- Geeignet für Rohre mit Durchmessern von DN20 bis DN1000.

- Ultraweites Turndown-Verhältnis von 1:2500, der Messbereich reicht von 0,1 Nm/s bis 250 Nm/s.

- Volldigitale Signalverarbeitung, höhere Genauigkeit, Langzeitstabilität.

Staurohr-Gasdurchflussmessgeräte

- How they work: Measure the difference between static and dynamic pressure of argon flowing past the probe.

- Why they’re suitable: Simple and durable solution for large pipeline applications with steady, high flow rates.

- Anwendungen: Industrial gas distribution, HVAC systems, and large-scale argon supply pipelines.

- Anwendbar für die Messung von verschmutzter und feuchter Luft

- Online-Autokalibrierung reduziert Datenabweichung

- hohe Empfindlichkeit, die untere Grenze liegt bei 5 Nm/s

- 1:60 breites Turndown-Verhältnis

- Bidirektionale Durchflussmessung

- Integrierte Druck- und Temperatursensoren zur Online-Überwachung von Gasdruck und -temperatur

- Keine beweglichen Teile, geringer Druckabfall

- Es wird nicht durch Vibrationen der Pipeline beeinträchtigt.

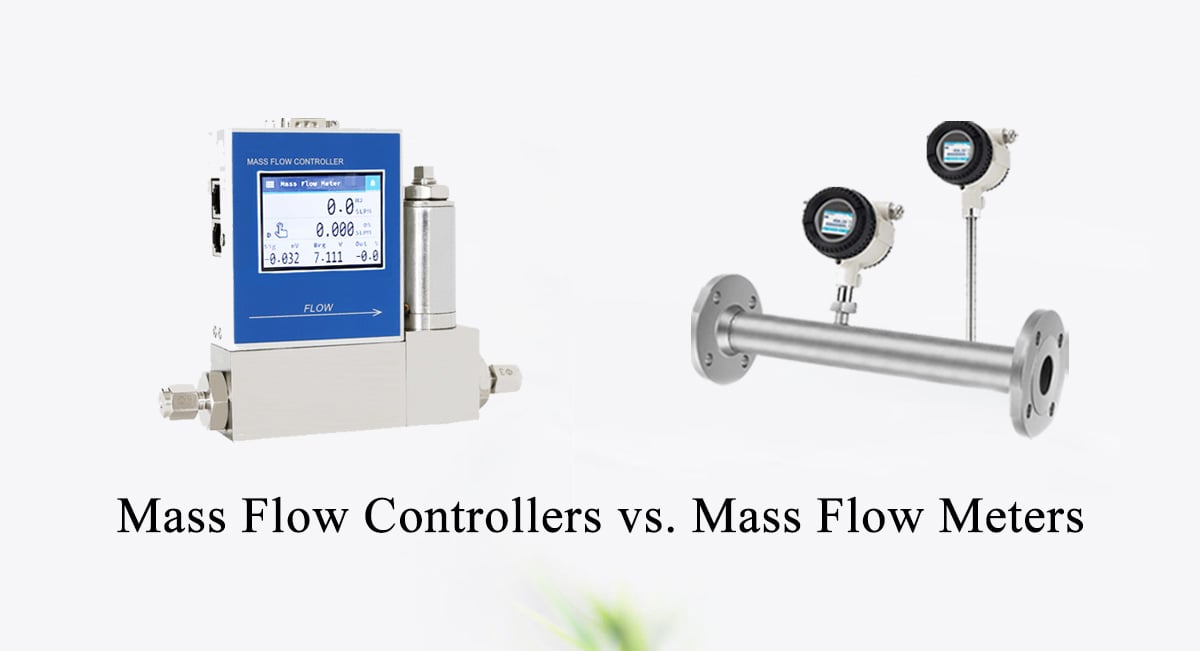

Gas Mass Flow Controllers (MFCs)

- How they work: Not only measure but also actively regulate the flow of argon by combining a thermal sensor with a control valve.

- Why they’re suitable: Provide precise, automated control of argon flow, which is essential for sensitive applications.

- Anwendungen: Semiconductor fabrication, pharmaceutical manufacturing, laboratory experiments, and any process requiring stable and repeatable flow control.

- Ultra-Low Flow Detection with High Accuracy from as low as 0.1 sccm

- Multi-Fluid, Multi-Range, and Multi-Principle Flexibility

- Fast Response and Stable Control with a control response time under 1 second

- Compact Design for Easy Integration

Coriolis-Durchflussmessgeräte

- How they work: Detect the mass flow of argon by measuring the deflection of vibrating tubes as gas passes through.

- Why they’re suitable: Offer the highest accuracy of all flow measurement technologies and provide direct mass flow readings independent of temperature or pressure changes.

- Anwendungen: High-purity industries such as electronics, specialty gas supply, and advanced R&D environments where absolute precision is non-negotiable.

- Hohe Genauigkeit bis zu ±0,1 %, gute Zuverlässigkeit

- Gute Nullpunktstabilität und Antistörungsleistung

- Keine beweglichen Teile, keine Wartung erforderlich

- Mehrfache digitale Kommunikation einschließlich Hart

How to Choose the Right Argon Flow Meter

Selecting the correct argon flow meter depends on several factors. Here are the main considerations:

4.1 Flow Rate Range

- For low-flow precision (e.g., lab research, semiconductor processes), mass flow controllers are ideal.

- For medium to high-flow ranges (e.g., welding, industrial use), thermal mass or pitot tube Gasdurchflussmesser may suffice.

4.2 Accuracy Requirements

- If process quality is critical (e.g., semiconductor production, pharmaceutical manufacturing), choose Coriolis flow meters.

- For general monitoring where approximate flow is sufficient, a pitot tube flow meter is cost-effective.

4.3 Cost and Budget

- Coriolis meters are the most accurate but come with high investment costs.

- Thermal mass meters strike a balance between cost and accuracy.

4.4 Pressure and Temperature Conditions

- High-pressure or varying temperature systems require meters with proper compensation (e.g., thermal mass or Coriolis).

- Low-pressure systems, such as welding setups, often use simple rotameters.

4.5 Application Environment

- Industrial welding: Pitot tube gas meters or digital thermal mass meters.

- Semiconductors and high-purity processes: Coriolis or high-precision thermal mass meters.

- Laboratory: Thermal mass meters or mass flow controllers depending on accuracy needs.

Argon plays a vital role in welding, electronics, pharmaceuticals, food packaging, and laboratory research. To maximize its efficiency and minimize costs, accurate flow measurement is essential. Among the available technologies, thermische Massendurchflussmesser, Pitot tube gas flow meters, gas mass flow controllers, and Coriolis-Durchflussmesser represent the most reliable solutions for different applications.

Choosing the right argon flow meter depends on your accuracy requirements, flow range, and process environment. For general monitoring, a Pitot tube may suffice, while high-precision applications in semiconductors or pharmaceuticals benefit from Coriolis or mass flow controllers. Thermal mass flow meters, meanwhile, strike an excellent balance for most laboratory and industrial applications.

By carefully matching the technology to the application, industries can ensure efficient use of argon, reduce costs, and maintain the highest process quality standards.