What Is Fuel?

Fuel is any material that can store potential energy and release it through combustion or another chemical reaction to produce power. It is the essential energy source for engines, power plants, industrial furnaces, and heating systems. Fuels exist in various forms liquid, gaseous, and solid, and each type has different chemical properties, viscosity, and energy density, which influence how it is stored, transported, and measured.

Accurate fuel measurement is crucial because even a small error can lead to significant financial losses, process inefficiencies, or equipment malfunctions. That’s where Kraftstoffdurchflussmesser ins Spiel kommen.

Inhaltsübersicht

Types of Fuel

Liquid Fuels

Common liquid fuels include diesel, gasoline, kerosene, jet fuel, biodiesel, and heavy oil.

- Diesel: High viscosity, commonly used in industrial engines and generators. Measurement challenges include temperature-dependent density changes and potential air bubbles.

- Benzin: Low viscosity and volatile, requiring precise sealing and vapor management in flow measurement.

- Kerosene and Jet Fuel: Require high accuracy and cleanliness; contamination can affect performance.

- Biodiesel: More viscous and may contain impurities that affect flow meter stability and calibration.

- Heavy Fuel Oil (HFO): Very viscous and often needs to be heated before measurement. This can complicate installation and calibration.

Gaseous Fuels

Typical gaseous fuels include natural gas, propane, butane, and hydrogen.

- Erdgas: Compressible, and its density changes significantly with temperature and pressure.

- Propane and Butane: Stored under pressure as liquids and converted to gas for combustion, requiring accurate flow control during phase change.

- Hydrogen: Extremely low molecular weight and high diffusivity, which makes measurement sensitive and requires specialized equipment.

Each fuel type poses unique challenges in measurement. Factors like viscosity, temperature, compressibility, and impurities all influence flow meter selection. Therefore, understanding fuel characteristics is the first step in choosing the right Kraftstoffdurchflussmesser.

What Is a Fuel Flow Meter?

A Kraftstoffdurchflussmesser is an instrument designed to measure the rate and total quantity of fuel flowing through a pipe or system. Depending on the measurement principle, it can measure Massenstrom (the actual amount of fuel) or Volumendurchfluss (the volume the fuel occupies).

Fuel flow meters are widely used in:

- Automotive and marine engine testing

- Power generation systems

- Industrial furnaces and burners

- Fuel distribution and transfer systems

- Aerospace and laboratory testing setups

The primary goal of a fuel flow meter is to provide accurate, repeatable measurements regardless of changes in temperature, pressure, or fuel type.

Best Recommended Fuel Flow Meters

Durchflussmessgeräte mit positiver Verdrängung (PD)

Arbeitsprinzip: PD meters directly measure the fuel volume by trapping fixed quantities between internal moving parts.

Vorteile:

- Sehr hohe Genauigkeit (±0,1-0,5%)

- Ideal for measuring viscous liquids such as diesel, lubricants, and heavy oils

- Unaffected by changes in flow profile or viscosity Beschränkungen:

- Not suitable for dirty fluids with large particles

- Requires regular maintenance due to mechanical wear

Am besten geeignet für: Diesel, heavy oil, and lubricating oil applications.

Doppelrotor-Verdrängungsdurchflussmesser (MT-ABR)

- Hohe Genauigkeit bis zu ±0,1 %, hoher Prozessdruck bis zu 110 bar (1595 psi)

- Äußerst lange Lebensdauer, wirtschaftlich und wartungsarm

- Stabiler Lauf mit tiefer Stimme

- Gute Antistörungsleistung und lange Nutzungsdauer

- Starke Anwendbarkeit bei Viskositätsänderungen

Zahnrad-Durchflussmesser mit niedrigem Durchfluss und positivem Verdrängungsvolumen MT-GF

- Konzipiert für Flüssigkeiten mit geringem Durchfluss ab 0,6 l/h

- Konzipiert für die Messung von Flüssigkeiten mit hoher Viskosität, die auch schwierige Medien wie Sirup, geschmolzenen Asphalt und Honig mit zuverlässiger Genauigkeit verarbeiten

- Hochpräzise Messung mit einer Genauigkeit von bis zu ±0,5%

- 150:1 wide turndown ratio

Coriolis-Durchflussmessgeräte

Arbeitsprinzip: Measures mass flow directly by detecting the Coriolis force generated as fuel flows through vibrating tubes.

Vorteile:

- Measures true mass flow independent of temperature or pressure

- High accuracy (±0.1–0.2%)

- Can measure density and temperature simultaneously Beschränkungen:

- Höhere Anfangskosten

- Sensitive to vibration in large pipelines

Am besten geeignet für: Precision fuel dosing, engine testing, and high-value applications involving various liquid or gaseous fuels.

Coriolis-Massedurchflussmesser in W-Form (MTD-ACMW)

- Hohe Genauigkeit bis zu ±0,1 %, gute Zuverlässigkeit

- Gute Nullpunktstabilität und Antistörungsleistung

- Keine beweglichen Teile, keine Wartung erforderlich

Coriolis-Massedurchflussmesser/-regler MTL20FE

- Konzipiert für die Messung von Gasen und Flüssigkeiten mit geringem Durchfluss.

- Hohe Präzision, gute Wiederholbarkeit. Für Flüssigkeiten kann die Messgenauigkeit ± 0,25% erreichen; für Gase kann die Messgenauigkeit ± 0,5% erreichen.

- Turn Down Ratio: 50:1 für digitale Massendurchflussregler; 100:1 für digitale Massendurchflussmesser.

- Ansprechzeit: Massendurchflussregler<0,2s; Massendurchflussmesser <0,1s

- Integrierter PID-Regler zur Regelung der Durchflussmenge.

Thermische Massendurchflussmessgeräte

Arbeitsprinzip: Measures gas mass flow based on the heat dissipation rate as fuel gas passes over a heated sensor.

Vorteile:

- Ideal for measuring low-flow or clean gas fuels

- Provides direct mass flow measurement without pressure or temperature compensation Beschränkungen:

- Not suitable for liquids

- Performance can be affected by humidity or particles in the gas

Am besten geeignet für: Natural gas, propane, and hydrogen flow measurement.

Explosionsgeschützter thermischer Massedurchflussmesser (MT212x-Ex)

- Explosionsschutzklasse: Ex db IIC T6 Gb / Ex tb IIIC T80°CDb.

- Geeignet für Rohre mit Durchmessern von DN20 bis DN1000.

- Ultraweites Turndown-Verhältnis von 1:2500, der Messbereich reicht von 0,1 Nm/s bis 250 Nm/s.

- Volldigitale Signalverarbeitung, höhere Genauigkeit, Langzeitstabilität.

- Die vollständig isolierte elektrische Struktur kann Feldstörungen vollständig herausfiltern.

Thermischer Gasmassendurchflussmesser / -regler (MTL20FD)

- Konzipiert für Gasmessungen mit geringem Durchfluss.

- Turn Down Ratio: 50:1 für digitale Massendurchflussregler; 100:1 für digitale Massendurchflussmesser.

- Ansprechzeit: Massendurchflussregler<0,2s; Massendurchflussmesser <0,1s

- Integrierter PID-Regler zur Regelung der Durchflussmenge

Turbinen-Durchflussmessgeräte

Arbeitsprinzip: Uses the rotation speed of a turbine blade to determine the volumetric flow rate.

Vorteile:

- Good accuracy at medium to high flow rates

- Compact and cost-effective Beschränkungen:

- Sensitive to viscosity changes

- Requires stable, clean fuel

Am besten geeignet für: Gasoline, kerosene, or aviation fuel under clean conditions.

Hochpräziser Turbinen-Durchflussmesser für Flüssigkeiten (LWGYMT-AJWL)

- Hohe Genauigkeit bis zu ±0,2 %, mit guter Wiederholbarkeit.

- 1:20-Abschaltverhältnis.

- Platzsparende Konstruktion mit einer Mindestbohrung von DN0,5.

- Farben und Aussehen können nach Wunsch angepasst werden

Ultraschall-Durchflussmessgeräte

Arbeitsprinzip: Measures flow velocity using the time difference between transmitted and received ultrasonic pulses.

Vorteile:

- No moving parts, minimal maintenance

- Suitable for both liquid and gas fuels

- Can be installed non-intrusively (clamp-on type) Beschränkungen:

- Accuracy depends on installation and pipe conditions

- Not ideal for very viscous or aerated fuels

Am besten geeignet für: Clean liquid fuels, pipeline monitoring, and large-diameter flow measurement.

Hochpräzisions-Ultraschall-Gasdurchflussmesser (MTS-LYNSB)

- Hohe Genauigkeit für Gas bis zu ±0,5%

- Keine beweglichen Teile, kein Druckverlust, keine Verstopfung der Leitung

- Keine Schmierung oder periodische Wartung

- Die Messung wird durch die Gaseigenschaften nicht beeinflusst

- 100:1 breites Turndown-Verhältnis

- Bi-direktionale Fähigkeit

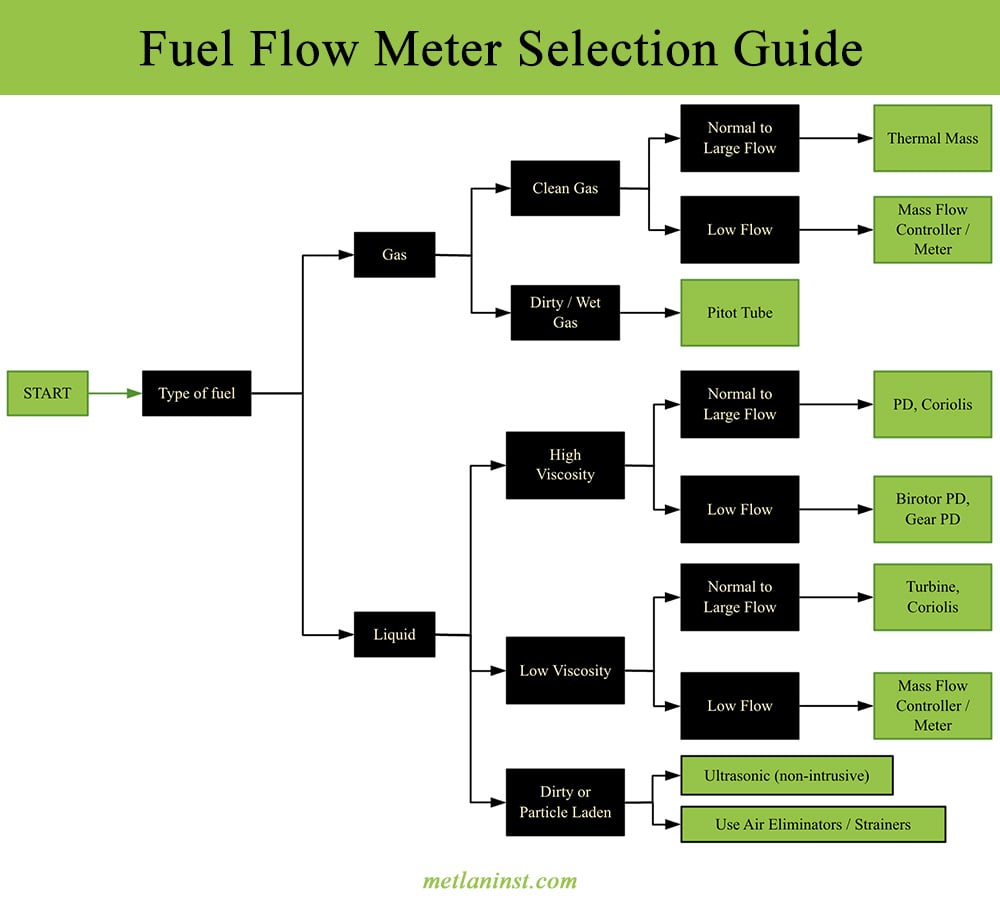

How to Choose the Right Fuel Flow Meter

Selecting the proper fuel flow meter depends on the type of fuel, flow conditions, accuracy requirements, and installation environment. Below are key factors to consider:

Fuel Type and Properties

Identify whether you are measuring liquid or gas fuel, its viscosity, density, and temperature range.

- For viscous liquids (diesel, oil) → choose Positive Verdrängung oder Coriolis meters.

- For light liquids (gasoline, kerosene) → Turbine oder Coriolis meters work well.

- For gas fuels (natural gas, hydrogen) → Thermische Masse oder Ultraschall meters are preferred.

Measurement Range and Accuracy

Define the required flow range and precision level.

- Laboratory and testing setups require ±0.2% or better accuracy (Coriolis, PD).

- Industrial transfer applications may allow ±1% accuracy (Thermal Mass, Turbine).

Pressure and Temperature Conditions

High-pressure or high-temperature systems require robust sensors and materials resistant to corrosion and thermal stress. Stainless steel or specialized alloys are typically used.

Maintenance and Installation

For remote or continuous operations, select meters with geringer Wartungsaufwand und digital output compatibility (e.g., 4–20 mA, RS485, or Modbus).

Clamp-on ultrasonic meters can be ideal when non-intrusive installation is required.

Cost and Lifecycle

Consider total ownership cost, not just the purchase price. A higher initial investment in a Coriolis or PD meter may yield long-term savings through accuracy, reduced downtime, and energy efficiency.

Fuel Flow Meter Selection Guide

| Selection Factor | Key Considerations | Recommended Flow Meter Types | Typical Fuel Examples |

|---|---|---|---|

| Fuel Phase | Determine whether the fuel is liquid oder gas. | – Liquid: Positive Displacement, Coriolis, Turbine – Gas: Thermal Mass, Ultrasonic | Liquid fuels: Diesel, Gasoline, Jet Fuel Gas fuels: Natural Gas, Propane, Hydrogen |

| Viskosität | High-viscosity fuels require meters that handle thick, slow-moving fluids. | – High viscosity: PD, Coriolis – Low viscosity: Turbine, Coriolis | Diesel, Heavy Oil → PD/Coriolis Gasoline, Kerosene → Turbine/Coriolis |

| Accuracy Requirement | Define precision needed for your process (e.g., testing vs. monitoring). | – High accuracy (±0.2%): Coriolis, PD – Medium (±0.5%–1%): Turbine | Engine testing → Coriolis, PD, Fuel transfer → PD/Turbine |

| Cleanliness / Particle Content | Dirty or particle-laden fuels can cause mechanical wear. | – Clean fuels: Turbine, Coriolis – Dirty fuels: Ultrasonic (non-intrusive) | Biodiesel (filtered) → PD Heavy oil with impurities → Ultrasonic |

| Budget / Lifecycle Cost | Consider total cost of ownership (accuracy, maintenance, calibration). | – Low-cost: Turbine – Mid-range: PD – Premium: Coriolis | Cost-sensitive sites → Turbine Long-term precision → Coriolis |

Applications of Fuel Flow Meters

Fuel flow meters are essential in multiple sectors:

- Automotive and Marine Engines: Real-time fuel consumption monitoring and efficiency analysis.

- Aviation: Precise jet fuel measurement for safety and performance.

- Power Generation: Monitoring fuel supply to turbines and boilers.

- Oil & Gas Industry: Custody transfer, blending, and leak detection.

- Laboratory and Research: Calibration, performance testing, and emission studies.

Accurate measurement not only improves operational efficiency but also helps meet environmental and safety regulations.

A Kraftstoffdurchflussmesser is more than just a measuring device—it is a critical component that ensures energy efficiency, process control, and cost management. Whether dealing with diesel, gasoline, natural gas, or hydrogen, selecting the right flow meter type can significantly impact performance and reliability.