Accurate control of gas flow is essential in modern industrial processes, laboratory systems, and advanced manufacturing. From semiconductor fabrication and analytical instruments to chemical processing and energy applications, gas flow must be not only measured but precisely regulated in real time. This is where the controlador térmico de caudal mássico (MFC) plays a critical role.

Unlike conventional flow control devices that rely on pressure or volumetric flow, a thermal mass flow controller directly measures and controls caudal mássico, making it particularly suitable for gas applications where density and temperature may vary. This article explains what a thermal mass flow controller is, how it works, how it differs from a thermal mass flow meter, and why it offers significant advantages for gas flow control.

Índice

What Is a Thermal Mass Flow Controller?

A controlador térmico de caudal mássico is an integrated instrument that measures, regulates, and maintains a set gas mass flow rate regardless of changes in pressure or temperature within a defined operating range.

A typical thermal mass flow controller consists of:

- A thermal mass flow sensor

- A control valve (proportional or solenoid-based)

- An electronic control circuit

- A setpoint input and feedback loop

The controller continuously compares the measured mass flow with the desired setpoint and automatically adjusts the valve position to maintain stable flow.

What Makes It “Mass” Flow Control?

Unlike volumetric devices, thermal MFCs measure fluxo de massa diretamente, usually expressed in:

- sccm (standard cubic centimeters per minute)

- slm (standard liters per minute)

- kg/h or g/h (in industrial systems)

This eliminates the need for external temperature or pressure compensation, which is especially important for gases.

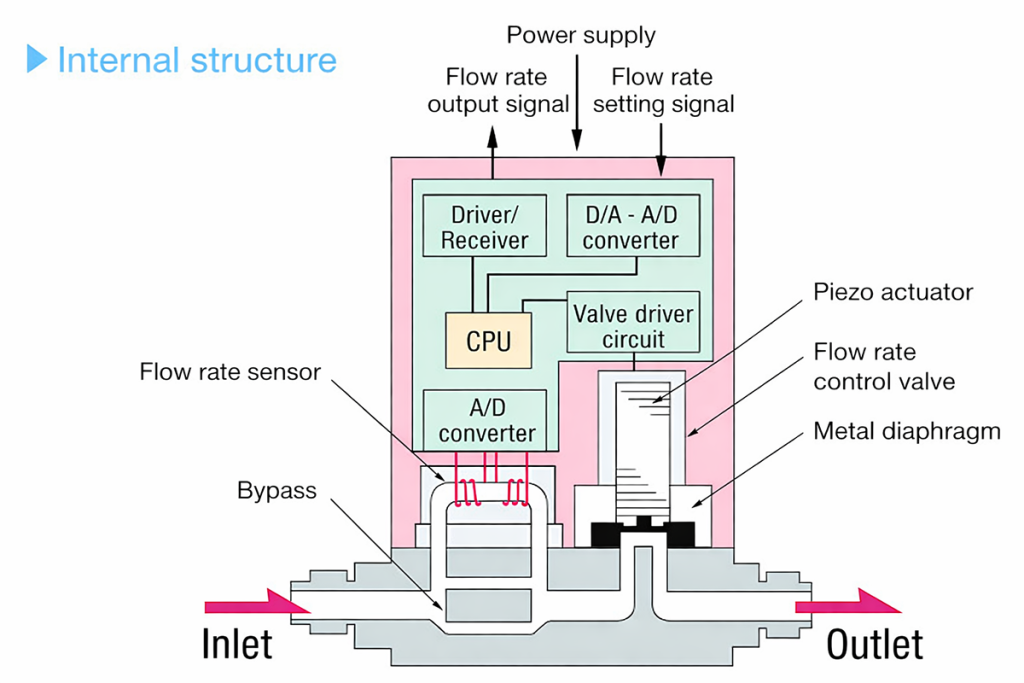

Working Principle of a Thermal Mass Flow Controller

The working principle of a thermal mass flow controller is based on transferência de calor.

Step-by-Step Operating Principle

- Gas Flow Through the Sensor The gas passes through a flow channel where two temperature sensors and a small heater are installed.

- Heat Transfer to the Gas The heater introduces a known amount of heat into the gas stream.

- Temperature Difference Measurement As gas flows, it carries heat downstream. The temperature difference between the upstream and downstream sensors is proportional to the caudal mássico of the gas.

- Mass Flow Signal Generation The sensor electronics convert this temperature difference into a precise mass flow signal.

- Closed-Loop Control The controller compares the measured flow with the user-defined setpoint.

- Valve Adjustment If the flow deviates from the setpoint, the control valve automatically opens or closes to correct it.

This closed-loop feedback control allows the thermal MFC to maintain highly stable and repeatable gas flow.

Thermal Mass Flow Controller vs Thermal Mass Flow Meter

Thermal mass flow controllers and medidores de caudal mássico térmico share similar sensing principles, but their functions and applications are fundamentally different.

Functional Difference

| Aspect | Medidor de caudal mássico térmico | Thermal Mass Flow Controller |

|---|---|---|

| Função principal | Measurement only | Measurement + control |

| Válvula de controlo | Not included | Integrated |

| Setpoint Input | Não | Yes |

| Flow Regulation | External device required | Automatic |

| Feedback Control | Não | Yes |

A thermal mass flow meter answers the question:

“How much gas is flowing?”

A thermal mass flow controller answers:

“How much gas is flowing, and how do I keep it exactly at the desired value?”

Application Difference

- Medidores de caudal mássico térmico

- Monitoring gas consumption

- Energy management

- Process diagnostics

- Deteção de fugas

- Thermal Mass Flow Controllers

- Precise gas dosing

- Process control

- Gas mixing and blending

- Automated production systems

In short, if your process requires active regulation, a flow meter alone is not sufficient.

Why Thermal Mass Flow Controllers Are Ideal for Gas Flow

Gas flow control presents unique challenges compared to liquids:

- Gas density changes with temperature and pressure

- Low flow rates are common

- High precision is often required

- Flow instability can affect product quality

Thermal mass flow controllers are specifically designed to address these challenges.

Medição direta do caudal mássico

Because thermal MFCs measure fluxo de massa diretamente, they are not affected by:

- Pressure fluctuations

- Temperature variations (within design limits)

This makes them far more reliable than volumetric flow controllers for gases.

High Accuracy at Low Flow Rates

Many gas applications require extremely small and stable flows:

- Semiconductor processes

- Laboratory experiments

- Calibration systems

Thermal mass flow controllers excel at low-flow measurement and control, where other technologies struggle.

Fast Dynamic Response

Because thermal MFCs measure mass flow direThe thermal sensing principle and electronic control allow:

- Rapid detection of flow changes

- Quick valve adjustments

- Stable control during transient conditions

This is critical for batch processes and gas switching applications.

Compact, Integrated Design

A single thermal MFC replaces:

- A flow meter

- A control valve

- A pressure regulator (in many cases)

- External control logic

This reduces system complexity, installation time, and potential leak points.

Wide Range of Gas Compatibility

Thermal mass flow controllers can be calibrated for:

- Ar

- Azoto (N₂)

- Oxigénio (O₂)

- Hidrogénio (H₂)

- Argon, helium, CO₂

- Specialty and mixed gases

Gas-specific calibration ensures optimal accuracy.

Digital Communication and Automation Ready

Modern thermal mass flow controllers support:

- Analog signals (0–5 V, 4–20 mA)

- Digital protocols (RS485, Modbus, DeviceNet)

- PLC and SCADA integration

This makes them ideal for automated and Industry 4.0 environments.

Metlan’s Thermal Mass Flow Controller

- Concebido para a medição de gases de baixo caudal.

- Rácio de redução: 50:1 para o controlador digital de caudal mássico; 100:1 para o medidor digital de caudal mássico.

- Tempo de resposta: controlador de caudal mássico <0,2s; medidor de caudal mássico <0,1s

- Controlador PID integrado para regular o caudal

- Medição direta do caudal mássico, compensação automática da temperatura

- Ecrã tátil

- Adequado para várias condutas de alta e baixa pressão.

Case Study of Metlan’s Thermal Mass Flow Controller

In chlorine production and chemical processing, precise chlorine gas flow measurement and control is essential for process stability, product quality, and plant safety. Chlorine (Cl₂) is a highly corrosive and toxic gas that requires specialized instrumentation to manage both accuracy and durability.

This case study highlights how our MTL20FD Thermal Mass Flow Controller was applied in a chlorine plant, providing accurate measurement in grams per hour (g/h) and enabling closed-loop control to optimize dosing and minimize risks.

Customer Challenges

The chlorine plant faced several operational challenges:

- Stable dosing required: Chlorine flow must be precisely controlled for chemical reactions to avoid overdosing or underdosing.

- Corrosion resistance: Standard flow meters failed quickly due to chlorine’s oxidizing nature.

- Process integration: The customer needed a device with 4–20 mA control signal for automatic regulation via DCS.

- Direct mass unit (g/h): Operators required g/h display for simplified process monitoring and reporting.

- Durability and safety: Equipment needed to perform reliably under 2–3 bar pressure without frequent maintenance.

Our Solution:

Key Technical Configuration of MTL20FD Thermal Mass Flow Controller

- Medium: Chlorine gas (Cl₂)

- Flow rate: 200 g/h

- Precisão: ±0,5%

- Display: Digital display, direct g/h readout

- Sensor: PTFE-type for chemical resistance

- Seal: FFKM (perfluoroether rubber) for long-term sealing in corrosive service

- Maximum Pressure: 3Mpa

- Connections: Ferrule type, ID 10 mm

- Control signal: 4–20 mA for DCS integration

- Power supply: 24 V DC

Calibration and Shipping Assurance

Every MTL20FD is factory-calibrated before delivery. The chlorine gas controller undergoes:

- Calibration on precision gas standards to ensure ±0.5% accuracy,

- Leak testing with FFKM seals, ensuring reliable sealing under corrosive gas,

- Final inspection and packaging for safe shipment.