Selecting the correct water flow meters is crucial for optimizing efficiency, ensuring accurate billing, and maintaining system performance. With a wide variety of flow meters available, each with different technologies and specifications, it can be challenging to know which one is best suited for your needs. This guide will help you understand key factors to consider when selecting a water flow meter, the most recommended types for water applications, and why these choices are optimal for different scenarios.

Table of Contents

Case Studies:

- Troubleshooting Electromagnetic Flowmeters: Impact of Gas and Solid Contaminants

- Electromagnetic Flow Meter Troubleshooting Due to Changes in Flow Conditions

Factors to Consider When Choosing a Water Flow Meter

When selecting a water flow meter, it’s essential to evaluate several key factors. Understanding these will allow you to narrow down the right type for your specific needs:

1. Water Quality

Water quality plays a significant role in determining the most suitable flow meter. For example, clean water allows for a broader range of meters, including mechanical types. However, for dirty, corrosive, or wastewater, more specialized meters like electromagnetic or ultrasonic meters are preferable, as they can handle impurities and chemical properties without clogging or degrading.

2. Flow Rate and Range

The range of flow rates you need to measure also impacts your meter choice. Some meters perform well at low flow rates, while others are more suited for high-volume flows. Understanding the required flow range helps prevent errors and ensures consistent accuracy.

3. Installation Environment

Some flow meters are highly sensitive to installation conditions, including pipe orientation, temperature, and pressure. It’s crucial to determine whether your system can accommodate a certain type of meter without significant modifications. For instance, ultrasonic meters can be installed non-intrusively, while mechanical meters need to be placed inside the pipe.

4. Accuracy Requirements

If precision is critical—such as in billing systems, industrial processes, or water treatment—choosing a highly accurate meter is essential. Certain flow meters, like Coriolis and electromagnetic meters, offer excellent accuracy, making them ideal for applications where precision matters.

5. Maintenance and Durability

Some flow meters have moving parts that are prone to wear, requiring regular maintenance. For long-term reliability, non-mechanical meters like ultrasonic or magnetic flow meters, which have no moving parts, are preferred. Assess the maintenance needs and the durability of the meter, especially if it’s being used in harsh or remote environments.

6. Budget Considerations

Cost is always a consideration. While high-precision flow meters may offer better performance, they can come with a higher price tag. It’s important to weigh the cost against the benefits you’ll get from the meter in terms of accuracy, lifespan, and reliability.

Recommended Water Flow Meter Types

Based on the factors mentioned above, here are the most recommended flow meter types for measuring water and why they are optimal for specific applications:

| Types | Best for | Pros. | Cons. |

| Electromagnetic Water Flow Meters | Clean and dirty water, wastewater, and applications where accuracy is key. | 1. Highly accurate for both clean and dirty water applications. 2. No moving parts, which minimizes maintenance. 3. Suitable for large pipes and high flow rates. 4. Ideal for harsh environments like wastewater treatment. | 1. Higher initial cost compared to other flow meters. 2. Only works with conductive liquids, such as water |

| Ultrasonic Water Flow Meters | Clean water, potable water, and non-intrusive installations | 1. Non-intrusive installation (clamp-on models available). 2. Suitable for large pipes and provides good accuracy for potable water systems. 3. No moving parts, meaning low maintenance. 4. Can measure both clean and slightly dirty water. | 1. Less accurate for water with large amounts of air bubbles or solids. 2. Higher cost compared to mechanical flow meters. |

| Turbine Water Flow Meters | Clean water applications, low-budget systems, and steady flow rates | 1. Cost-effective and relatively easy to install. 2. Provides good accuracy for clean, steady-flow water applications. 3. Simple design with readily available parts. | 1. Not suitable for dirty water due to clogging risks and wear on the rotor. 2. Requires regular maintenance because of moving parts. 3. Less accurate for water with variable flow rates |

| Vortex Water Flow Meters | Industrial applications with fluctuating flow rates and moderate impurities | 1. No moving parts, meaning less maintenance is required. 2. Handles a wide range of temperatures and pressures. 3. Good for fluctuating flow rates and water with moderate impurities. 4. Can measure both liquids and gases. | 1. Not ideal for highly dirty water. 2. Generally less accurate than electromagnetic or ultrasonic meters. 3. May experience reduced accuracy in very low flow rates. |

| Positive Displacement (PD) Water Flow Meters | Low flow rate applications and highly accurate billing systems | 1. Highly accurate, especially for low flow rates. 2. Ideal for billing applications. 3. No external power required. | 1. Maintenance-intensive due to moving parts. 2. Not suitable for high flow rates or water with solid impurities. |

| Differential Pressure (DP) Water Flow Meters | High-pressure systems, large water distribution networks, and water treatment plants. | 1. Robust and reliable for large-scale, high-pressure water systems. 2. Cost-effective for large-scale water distribution. 3. Suitable for high flow rates. | 1. Causes pressure drop in the system. 2. Requires periodic recalibration for accurate readings. 3. Less accurate than modern technologies like ultrasonic or magnetic meters. |

1. Electromagnetic (Magnetic) Flow Meters

- How it works: These meters use electromagnetic fields to measure the flow of water. The flowing water (a conductive liquid) generates voltage as it passes through the meter’s magnetic field. This voltage is directly proportional to the flow rate.

Why recommended: Magnetic flow meters are highly accurate and reliable. They have no moving parts, which minimizes maintenance and makes them ideal for measuring both clean and dirty water. Their durability also makes them well-suited for industrial applications like wastewater management, where water quality may vary. Additionally, they handle high flow rates with ease, making them a go-to choice for large-scale municipal water supply systems.

2. Ultrasonic Flow Meters

- How it works: Ultrasonic flow meters use sound waves to measure water flow. In transit-time meters, sound waves are sent both downstream and upstream, and the time difference between the two is used to calculate the flow rate. Doppler ultrasonic meters measure the frequency shift caused by sound waves reflecting off particles in the water.

Why recommended: These meters are highly accurate, suitable for large pipelines, and provide non-intrusive installation options (clamp-on). Ultrasonic meters are also excellent for measuring flow in potable water systems, as they don’t require direct contact with the water, reducing the risk of contamination. They’re favored in industries where installation flexibility is crucial and where consistent flow measurement accuracy is required.

3. Turbine Flow Meters

- How it works: Turbine flow meters rely on a spinning rotor placed in the flow of water. The speed at which the rotor spins is proportional to the flow rate.

Why recommended: Turbine flow meters are cost-effective and relatively simple to install and operate. They are ideal for measuring clean water in steady-flow conditions, such as residential water supply systems or irrigation systems. However, because they have moving parts, they are less suited for dirty or corrosive water, which could lead to wear and tear.

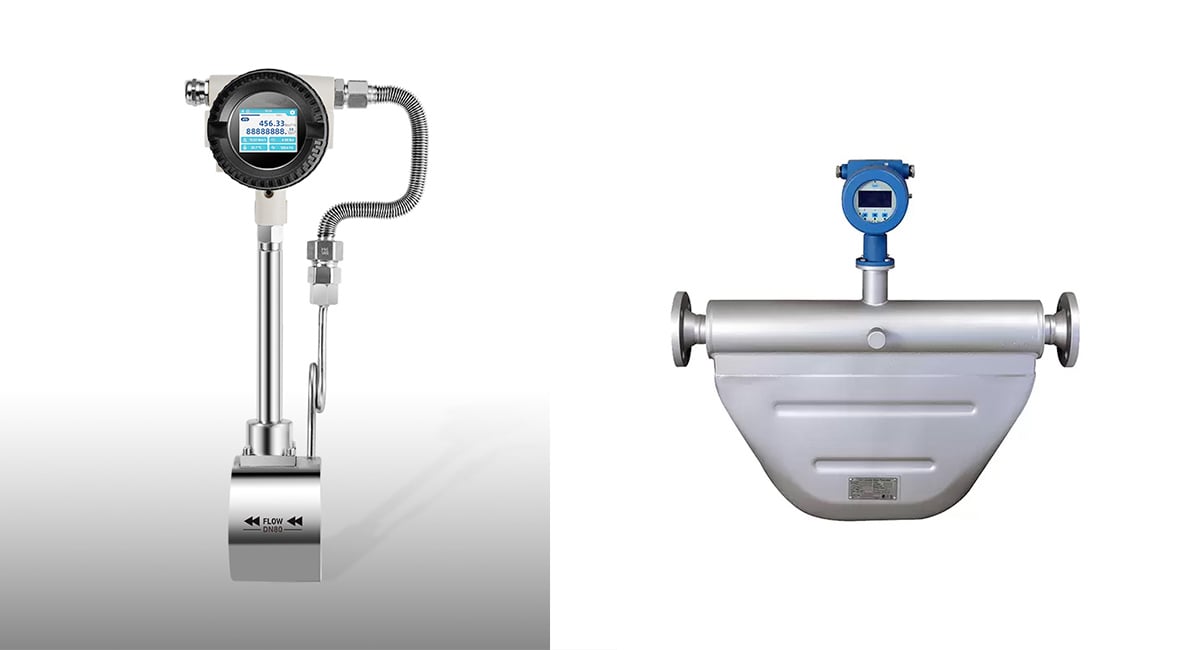

4. Vortex Flow Meters

- How it works: Vortex meters work by placing a bluff body in the flow stream. As water passes around this body, vortices are created. The frequency of these vortices is measured and directly related to the flow rate.

Why recommended: Vortex meters are durable and can handle a variety of fluids, including water with impurities. They have no moving parts, which makes them lower-maintenance than mechanical meters. Vortex meters are often used in industrial environments where water flow fluctuates or where there are mild impurities in the water. They also function well across a wide range of temperatures and pressures.

5. Positive Displacement (PD) Flow Meters

- How it works: PD meters work by capturing a fixed amount of water in compartments and then counting the number of times these compartments fill and empty to determine flow rate.

Why recommended: Positive displacement meters are highly accurate, making them ideal for billing systems where every drop of water counts. They are widely used in residential and commercial water meters, especially in smaller pipelines where low flow rates are common. Their mechanical design does require maintenance, but for small-scale applications, their precision outweighs the need for occasional upkeep.

6. Differential Pressure (DP) Flow Meters

- How it works: DP flow meters measure the pressure drop across a constriction (like an orifice plate or venturi tube) to calculate flow rate.

Why recommended: These meters are robust and can handle high flow rates and pressures. While they cause a slight pressure loss, they are reliable and commonly used in large water distribution networks or water treatment plants where long-term performance is critical. They are also cost-effective for large-scale applications.

Choosing the Right Flow Meter for Your Application

Given the different types of flow meters, selecting the right one depends on your specific application and the conditions under which you’ll be measuring water flow. Here’s a quick breakdown to guide your decision:

- For potable water systems: Consider ultrasonic or turbine flow meters. Ultrasonic is more expensive but offers non-intrusive installation, while turbine meters are more budget-friendly for clean water applications.

- For wastewater or dirty water: Electromagnetic (magmeters) or vortex meters are best. Magmeters are ideal for dirty or corrosive water, while vortex meters can handle fluids with moderate impurities.

- For precise billing: Positive displacement flow meters provide the most accuracy at low flow rates, making them perfect for residential or commercial billing applications.

- For industrial water measurement: Vortex or DP flow meters work well in industrial settings where water flow can be variable, and durability is key.

- For large-scale municipal systems: Electromagnetic or differential pressure flow meters are suited for large pipes and high flow rates typical in municipal water distribution.

Choosing the right water flow meter involves balancing the need for accuracy, installation constraints, water quality, and budget. Electromagnetic flow meters stand out as the most versatile choice for both clean and dirty water, while ultrasonic and positive displacement meters excel in specific scenarios like non-intrusive installations and highly accurate billing systems. By understanding the unique demands of your water system, you can select the best flow meter to optimize performance and ensure long-term reliability.

Leave a comment