Wastewater is a critical byproduct of both residential and industrial activities, and measuring its flow accurately is essential for efficient treatment, environmental compliance, and resource management. To ensure the proper treatment and disposal of wastewater, specialized flow meters are used to monitor flow rates, allowing for optimization of treatment processes, regulatory reporting, and cost management.

Table of Contents

Case Studies:

- Custom DN600 Electromagnetic Flow Meter for Wastewater Treatment

- Wastewater Zero Discharge Process in Power Plants

What is Wastewater?

Wastewater refers to any water that has been affected by human use. It includes water from residential, industrial, commercial, or agricultural activities that carries various contaminants. Once used, this water needs to be treated before being released back into the environment to avoid harming ecosystems and public health.

Wastewater can be broadly classified into two main categories:

- Municipal Wastewater (Sewage): This includes water from homes, schools, hospitals, and businesses. It contains human waste, food scraps, chemicals, and other organic and inorganic materials.

- Industrial Wastewater: This comes from industrial and manufacturing processes. Depending on the industry, it may contain harmful chemicals, metals, and other pollutants that require special treatment.

Examples of Wastewater

- Domestic Sewage: Wastewater from households, including water from sinks, toilets, washing machines, and dishwashers. This type of wastewater typically contains organic materials, soap, grease, and small amounts of chemicals.

- Stormwater Runoff: Water that originates from rain and is directed into storm drains. It often carries pollutants like oil, chemicals, and debris from streets and highways.

- Agricultural Runoff: This includes water from irrigation and livestock operations. It may contain pesticides, fertilizers, animal waste, and sediments.

- Industrial Effluent: Wastewater from factories, power plants, and refineries. It can contain toxic chemicals, heavy metals, oils, and solvents that are hazardous to the environment and require extensive treatment.

- Process Water: Water used in industrial processes, such as cooling, heating, or as part of the manufacturing process, that becomes contaminated during use.

Recommended Wastewater Flow Meters

Given the complex and varying nature of wastewater, it’s essential to choose the right flow meter that suits the specific conditions of your wastewater system. Here are the most recommended flow meters for wastewater applications, including why they’re suited for the task, as well as their pros and cons.

1. Electromagnetic (Magnetic) Flow Meters

Best for: Municipal wastewater, industrial wastewater, slurries, and conductive liquids.

Pros:

- Highly accurate for measuring conductive liquids, such as wastewater and slurries.

- No moving parts, which reduces maintenance and increases reliability in harsh conditions.

- Can handle high-solid content without clogging or losing accuracy.

- Suitable for large pipelines with varying flow rates.

Cons:

- Only works with conductive liquids, which may limit its application with certain types of industrial wastewater.

How it Works: Electromagnetic flow meters (mag meters) use the principle of electromagnetic induction to measure the flow rate of conductive liquids, like wastewater. As the wastewater passes through a magnetic field, it generates a voltage that is proportional to the flow rate. Check how to choose electromagnetic flow meters here.

Why Recommended: Electromagnetic flow meters are widely used in wastewater treatment plants because of their accuracy and ability to handle liquids with high levels of suspended solids. Their durability and low maintenance needs make them ideal for both municipal and industrial wastewater applications, where flow conditions can be unpredictable.

2. Ultrasonic Flow Meters

Best for: Non-intrusive installations, clean and dirty wastewater, and large pipelines.

Pros:

- Non-intrusive installation (with clamp-on models) means no need to cut the pipe or disrupt the flow.

- No moving parts, so they require little maintenance.

- Suitable for both clean and dirty wastewater, depending on the type of ultrasonic meter used.

- Works well with large pipes and in hard-to-reach areas.

Cons:

- Accuracy can be affected by changes in temperature and pressure.

- Less accurate when used with wastewater containing a high concentration of air bubbles or particles (for transit-time meters).

How it Works: Ultrasonic flow meters use sound waves to measure the velocity of the wastewater. They can be either transit-time meters (for clean or partially clean wastewater) or Doppler meters (for dirty wastewater with particles or air bubbles). These meters are available in both clamp-on and inline configurations.

Why Recommended: Ultrasonic flow meters are ideal for wastewater applications that require non-invasive measurement. Their flexibility and ability to measure a wide range of wastewater types make them a popular choice in both municipal and industrial settings, particularly for larger pipelines or temporary installations.

3. Open Channel Flow Meters

Best for: Measuring flow in open channels, including streams, rivers, and wastewater treatment plants.

Pros:

- Ideal for open environments, such as rivers, stormwater drains, and wastewater treatment plants.

- Can measure both low and high flow rates with good accuracy.

- No moving parts, meaning lower maintenance requirements.

Cons:

- Can be affected by debris or blockages in the open channel.

- Requires specific channel design (like weirs or flumes) for accurate measurements.

How it Works: Open channel flow meters are designed to measure the flow of wastewater in open systems where water flows without being fully enclosed in pipes. These meters typically use weirs or flumes combined with sensors to determine flow rates.

Why Recommended: Open channel flow meters are the best choice for applications where wastewater flows in open channels or systems, such as stormwater runoff or certain sections of wastewater treatment plants. Their ability to measure flow in non-enclosed environments makes them crucial for these applications.

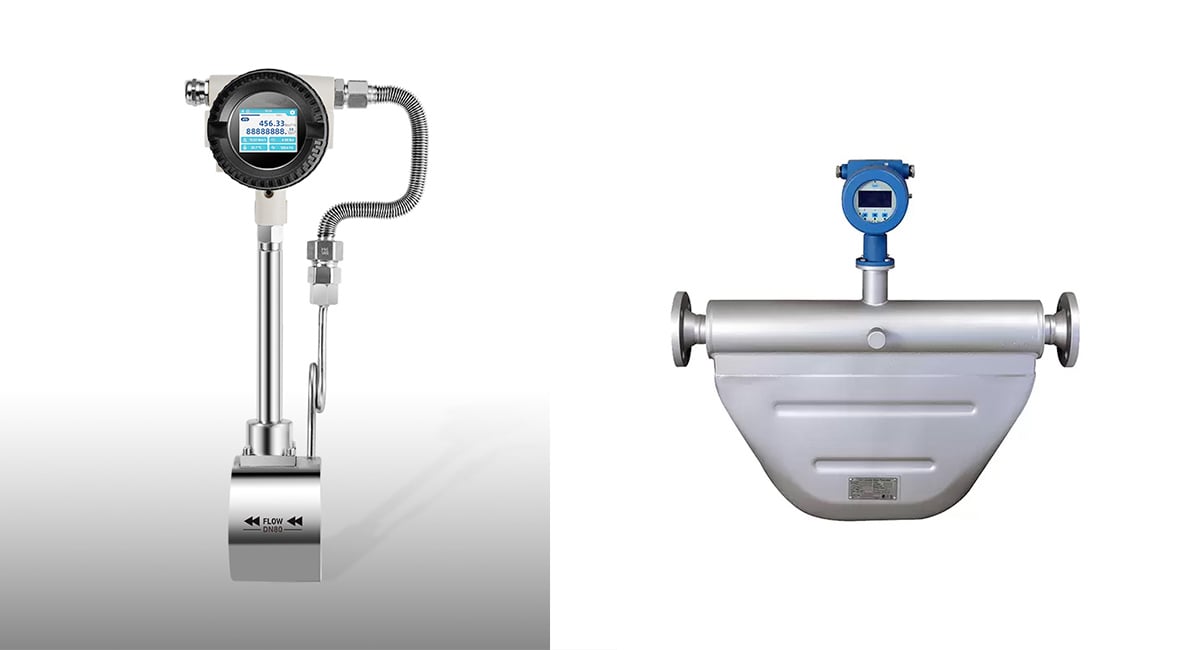

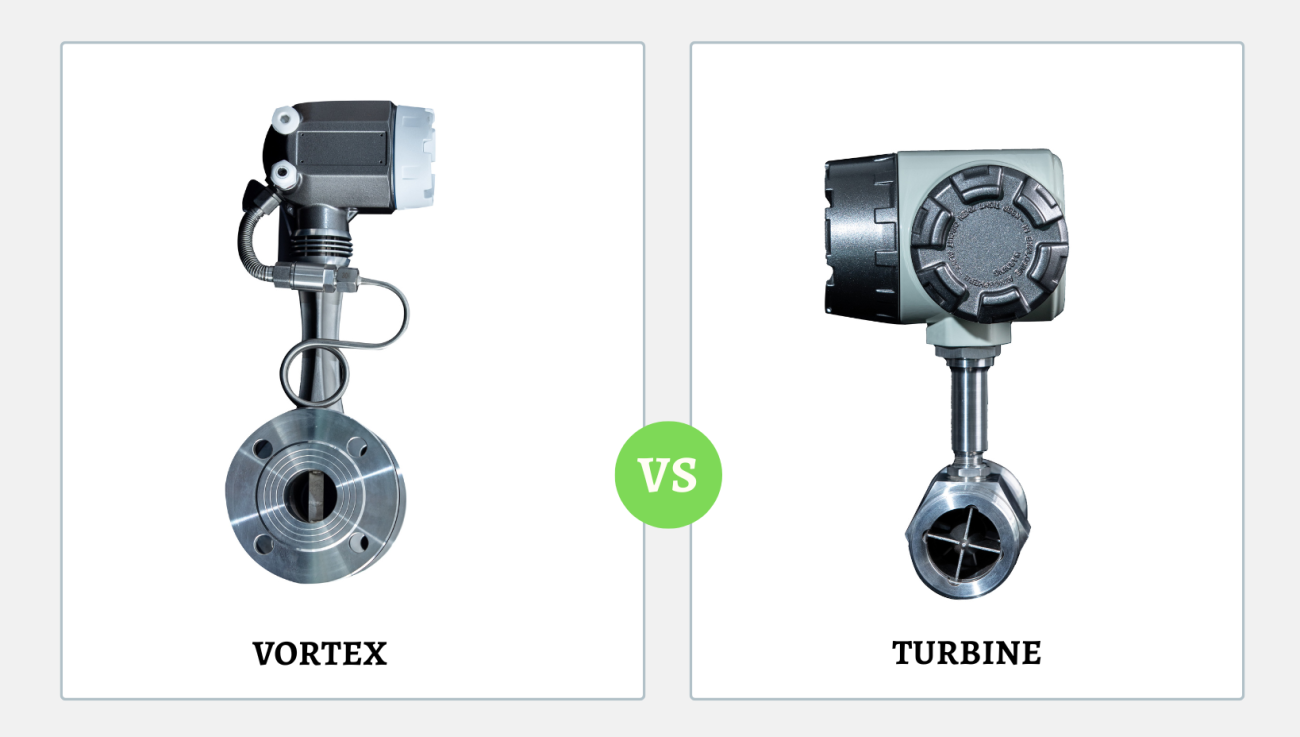

4. Vortex Flow Meters

Best for: Industrial wastewater with high temperatures or fluctuating flow rates.

Pros:

- No moving parts, resulting in minimal maintenance.

- Can handle high-temperature and high-pressure wastewater.

- Suitable for measuring gases and steam in wastewater treatment plants.

- Durable and resistant to harsh environmental conditions.

Cons:

- Sensitive to vibration and flow disturbances, which can affect accuracy.

- Not ideal for low flow rates or fluids with large particulates, as these can interfere with vortex shedding.

- Less accurate for viscous or high-solid-content wastewater.

How it Works: Vortex flow meters measure the flow of wastewater by detecting the frequency of vortices shed by a bluff body placed in the flow stream. The frequency of these vortices is proportional to the flow rate.

Why Recommended: Vortex flow meters are often used in industrial wastewater applications where the liquid may be at high temperature or pressure. Their durability and resistance to challenging conditions make them suitable for wastewater that contains gases or steam.

5. Differential Pressure (DP) Flow Meters

Best for: Low-cost, general wastewater applications, and moderate flow rates.

Pros:

- Low cost compared to other types of flow meters.

- Can handle a wide range of flow rates and pipe sizes.

- Widely available and easy to install.

Cons:

- Less accurate than more advanced flow meters like Coriolis or electromagnetic meters.

- Creates a pressure drop in the system, which may reduce efficiency.

- Requires frequent maintenance, as the orifice or nozzle can wear out over time.

- Not suitable for wastewater with high solids content or slurries, as these can clog or damage the meter.

How it Works: Differential pressure flow meters measure the flow rate of wastewater by determining the pressure drop across a restriction (such as an orifice plate, venturi tube, or nozzle) in the pipeline.

Why Recommended: Differential pressure flow meters are commonly used in wastewater applications where budget constraints are a consideration. They are cost-effective and suitable for many general wastewater flow measurement applications, particularly where moderate accuracy is acceptable and the wastewater does not contain high levels of solids or particulates. However, their tendency to clog and require frequent maintenance makes them less suitable for more challenging wastewater environments.

Comparison of Wastewater Flow Meters: Pros and Cons

To summarize, let’s compare the recommended flow meters for wastewater:

| Flow Meter Type | Best For | Pros | Cons | Why Recommended |

|---|---|---|---|---|

| Electromagnetic (Mag) | Municipal and industrial wastewater, slurries | – Highly accurate – No moving parts – Handles high solids | – Only works with conductive liquids | Ideal for wastewater with high solids and varying flow rates |

| Ultrasonic | Non-intrusive installations, clean/dirty wastewater | – Non-intrusive – No moving parts – Works for large pipes | – Less accurate with air bubbles or particulates | Great for large pipelines and hard-to-reach areas without cutting the pipe |

| Open Channel | Open wastewater channels (e.g., stormwater) | – Ideal for open environments – No moving parts | – Not suitable for closed-pipe systems – Prone to debris blockages | Best for open channels and wastewater treatment plants |

| Vortex | High-temperature/pressure industrial wastewater | – No moving parts – Can handle steam/gases – Durable | – Not ideal for low flow or high solids – Sensitive to vibrations | Ideal for wastewater containing gases, steam, or high-pressure flows |

| Differential Pressure | Low-cost, general wastewater applications | – Low cost – Easy to install – Wide flow range | – Creates pressure drop – Clogs with high solids – Maintenance | Cost-effective option for general applications with low to moderate accuracy |

How to Choose the Best Flow Meter for Wastewater Applications

Selecting the right wastewater flow meters require a clear understanding of the wastewater’s characteristics, the operational environment, and the accuracy needed. Here are the key factors to consider:

1. Type of Wastewater

Different flow meters are better suited for different types of wastewater. For example, municipal sewage with high solids content is best measured with an electromagnetic meter, while clean industrial effluent may be suitable for an ultrasonic meter.

2. Flow Rate

Understanding the expected flow rate in your system is critical. For high flow rates in large pipes, electromagnetic or ultrasonic meters may be ideal, while low flow rates might require more specialized meters like vortex or differential pressure meters.

3. Solids Content

Wastewater often contains particulates, which can clog or interfere with certain types of flow meters. Electromagnetic and ultrasonic meters are well-suited for wastewater with high solids content, while differential pressure and vortex meters may struggle in these conditions.

4. Installation Environment

Consider the physical installation environment. In some cases, non-intrusive meters like clamp-on ultrasonic meters are ideal because they don’t require cutting into the pipe or stopping the flow. In other cases, inline meters might be more appropriate.

5. Accuracy Requirements

The required level of accuracy depends on the application. Regulatory compliance, billing, and pollution control require highly accurate flow meters, such as electromagnetic or Coriolis meters. General process monitoring may allow for less accuracy, in which case differential pressure or vortex meters could be a cost-effective solution.

6. Budget

Flow meters come in a wide range of price points. Electromagnetic and ultrasonic meters tend to be more expensive due to their advanced technology and accuracy, while differential pressure meters are more affordable but may require more frequent maintenance.

Here’s a quick recap of the recommended flow meters for wastewater applications:

- Electromagnetic Flow Meters (Mag Meters): Ideal for both municipal and industrial wastewater with high solids content. They offer high accuracy, low maintenance, and are suitable for large pipelines.

- Ultrasonic Flow Meters: Best for non-intrusive installations and large pipelines, and are capable of handling both clean and dirty wastewater. These meters offer flexibility and are suitable for difficult-to-reach installations.

- Open Channel Flow Meters: The go-to choice for open wastewater channels, such as stormwater drains and treatment plant overflow channels, where no closed pipes are present.

- Vortex Flow Meters: Recommended for industrial applications where wastewater contains gases, steam, or is subjected to high temperatures and pressures. These meters are durable and low-maintenance.

- Differential Pressure Flow Meters: A cost-effective solution for general wastewater applications where moderate accuracy is sufficient. However, they require frequent maintenance and are less suitable for high solids content.

By understanding the specific characteristics of your wastewater and aligning those with the capabilities of different flow meters, you can choose the most effective and efficient solution for your system. Whether you’re managing a municipal wastewater treatment facility, an industrial process, or an open channel system, selecting the right flow meter is key to ensuring reliable operation and compliance.

Leave a comment