Slurries are a mixture of solids suspended in a liquid. They are commonly found in many industrial processes, and measuring the flow of slurries accurately is crucial for efficiency, safety, and cost management. However, due to the complex nature of slurries, selecting the right flow meter can be challenging.

Table of Contents

Case Study:

What is slurry?

A slurry is a mixture of solid particles suspended in a liquid. The solid particles can vary widely in size, from small, fine particles to large, coarse ones. The liquid component of the slurry acts as a carrier fluid that helps transport the solid particles. Slurries can be highly viscous, abrasive, and often cause wear and tear on equipment due to the solid content.

The proportion of solids in slurries can vary greatly depending on the application, ranging from a few percent solids to more than 50% in some cases. These mixtures are often pumped through pipelines for transport, making accurate flow measurement critical for efficient processing and cost control.

Examples and Industries Where Slurries Are Common

Slurries are used in various industries, each with its own specific type of slurry:

- Mining and Minerals Processing:

- Ore Slurries: Mixtures of finely crushed ore and water used in mineral extraction processes.

- Tailings: Residual slurries left over after the extraction of minerals from ore, often containing sand, clay, and other materials.

- Food and Beverage Industry:

- Fruit Pulp and Juice Concentrates: Slurries of fruit solids and juices used in the production of beverages and food products.

- Starch Slurries: Used in food processing to create products like sauces and gravies.

- Construction:

- Concrete and Cement Slurries: Mixtures of cement, sand, and water used in building construction.

- Drilling Mud: A slurry of water, clay, and other additives used in drilling operations to lubricate and cool the drill bit and to carry out drill cuttings.

- Water and Wastewater Treatment:

- Sludge: Semi-solid slurry composed of water and waste solids that is treated to extract usable water or safely dispose of the waste.

- Lime Slurry: Used in water treatment plants to adjust pH levels.

- Paper and Pulp Industry:

- Pulp Slurry: A mixture of wood fibers and water used in the paper-making process.

- Recycled Paper Slurry: Mixture of shredded recycled paper and water for creating new paper products.

Why Do We Need Slurry Flow Meters?

Accurate measurement of slurry flow is essential for several reasons:

- Process Control and Efficiency

Slurry measurement helps ensure that the right amount of solids and liquid is being transported through the process. Whether it’s mixing, separation, or pumping, knowing the precise flow rate allows for better control over the process, reducing waste and improving efficiency.

- Cost Management

Measuring slurry flow accurately can help manage costs by ensuring that resources are used efficiently. For example, in mining, accurate measurement of ore slurries can help optimize the extraction process, reducing energy usage and improving overall productivity.

- Equipment Protection

Slurries can be abrasive and cause significant wear and tear on equipment, especially pumps and pipelines. Monitoring flow rates can help detect issues such as clogs or excessive wear early, allowing for preventive maintenance and avoiding costly repairs.

- Safety and Environmental Compliance

Improper handling and measurement of slurries can lead to safety hazards and environmental issues. Accurate flow measurement ensures that slurries are transported and treated safely, minimizing risks of spills, leaks, and overflows.

- Regulatory Compliance

In industries such as mining and wastewater treatment, regulatory bodies often require precise measurements and reporting of slurry handling to ensure safe and responsible environmental practices. Accurate flow meters help industries meet these compliance requirements.

Recommended Slurry Flow Meters

Measuring the flow of slurries can be challenging due to their unique characteristics, such as high viscosity, solid content, and abrasiveness. Here are some of the most recommended types of flow meters for slurry applications, along with their pros and cons:

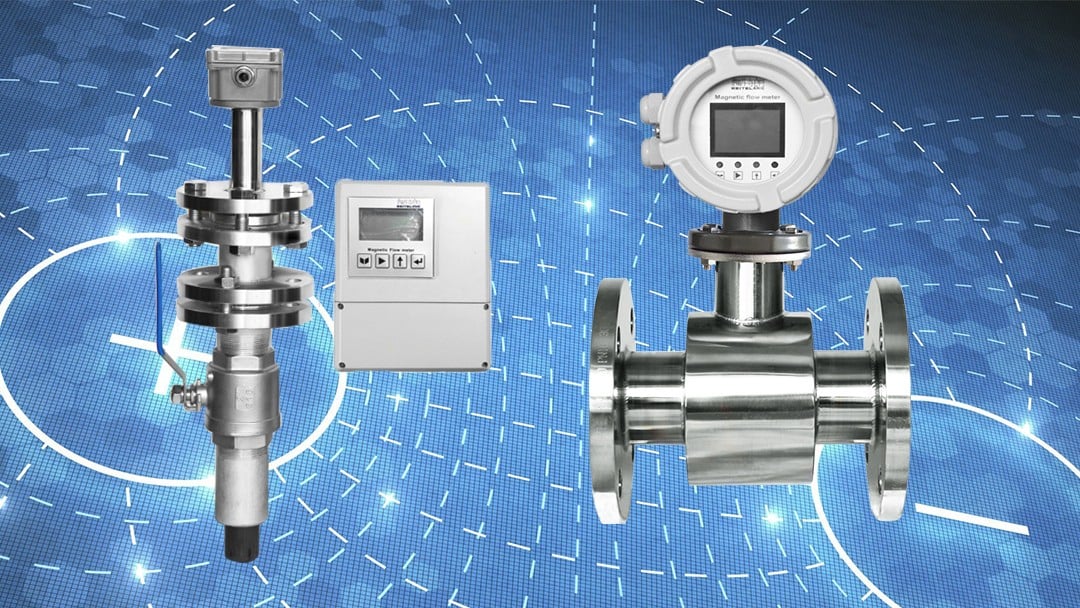

1. Electromagnetic Flow Meters (Mag Meters)

Best for: High-viscosity slurries, mining, wastewater, and other industrial applications.

How it Works: Electromagnetic flow meters operate using Faraday’s law of electromagnetic induction. They measure the flow rate by generating a magnetic field and detecting the voltage produced as the conductive slurry passes through it. If you’re intereted in mag meters, check how to choose electromagnetic flow meters here.

Pros:

- Highly accurate for conductive slurries.

- No moving parts, which reduces maintenance and minimizes wear.

- Handles high solid content without clogging or affecting accuracy.

- Works well with large pipeline diameters.

Cons:

- Only works with conductive liquids, which may limit its application for non-conductive slurries.

Why Recommended: Electromagnetic slurry flow meters are highly accurate and reliable, making them ideal for handling slurries in mining, wastewater, and other industries. Their ability to measure slurries with high solid content without clogging is one of their key advantages. It’s also one of the best chemical flow meters.

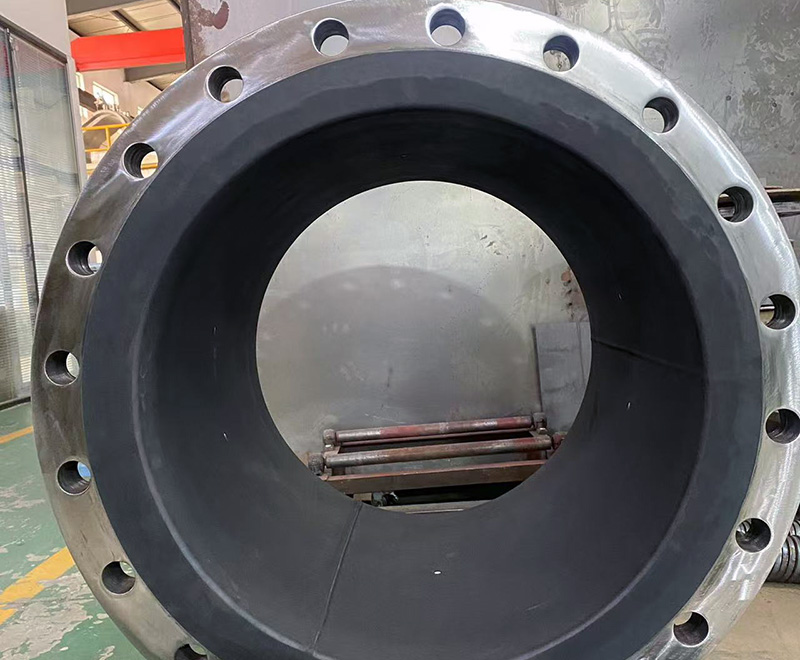

Case Study of Slurry Flow Meter

Here’s a case of DN600 electromagnetic flow meter with 6 electrodes. Please click the photos below to check the details.

2. Coriolis Flow Meters

Best for: High-viscosity, high-density slurries, and critical process control applications.

How it Works: Coriolis flow meters measure the mass flow rate of slurries by detecting the phase shift caused by the Coriolis effect as the slurry flows through vibrating tubes.

Pros:

- Measures mass flow directly, independent of temperature, pressure, or viscosity changes.

- Extremely accurate and ideal for precision applications.

- Can handle a wide range of viscosities and densities.

Cons:

- Requires specific installation conditions, including support for the vibrating tubes.

- Expensive, with high initial costs and maintenance requirements.

- Not suitable for large pipe diameters or high solid content slurries, as the vibrating tubes may become clogged.

Why Recommended: Coriolis slurry flow meters are highly accurate and suitable for critical process control, such as in chemical and food processing industries. They are best used for slurries and where precision measurement is essential, despite their higher costs and specific installation requirements.

3. Ultrasonic Flow Meters

Best for: Non-invasive measurements, clean to moderately dirty slurries, and applications where installation flexibility is required.

How it Works: Ultrasonic flow meters use sound waves to measure the velocity of the slurry. They are available in two main types: transit-time (for clean or slightly dirty slurries) and Doppler (for slurries with high solid content).

Pros:

- Non-intrusive options (clamp-on models) are available, meaning no need to cut the pipe or interrupt the flow.

- No moving parts, leading to lower maintenance needs.

- Suitable for large pipe sizes and applications where installation flexibility is important.

Cons:

- Can be more expensive than some mechanical flow meters.

- Less accurate for slurries with high solid content, especially with transit-time meters.

- Sensitive to temperature and pressure changes, which can affect performance.

Why Recommended: Ultrasonic flow meters are favored for their non-intrusive installation, making them ideal for retrofitting existing systems or in applications where downtime must be minimized. Their flexibility and ability to handle moderately dirty slurries make them a versatile choice.

4. Differential Pressure (DP) Flow Meters

Best for: Slurries with moderate viscosity, cost-effective general-purpose applications.

How it Works: DP flow meters measure the pressure drop across a restriction (e.g., orifice plate, venturi tube) to determine the flow rate of the slurry.

Pros:

- Cost-effective compared to other types of flow meters.

- Can be used with a wide range of slurries and pipe sizes.

- Simple design and easy to install.

Cons:

- Less accurate compared to more advanced meters like Coriolis or electromagnetic meters.

- reates a pressure drop, which may affect system efficiency.

- Requires regular maintenance, as the restriction can wear out or clog.

Why Recommended: Differential pressure flow meters are popular for their cost-effectiveness and versatility. They are suitable for general-purpose applications where high precision is not the primary concern, but consistent flow measurement is still needed.

Choosing the Right Slurry Flow Meters

Selecting the best flow meter for slurry applications depends on understanding the slurry’s characteristics, including viscosity, solid content, and abrasiveness, as well as the specific requirements of your process. Each flow meter type offers distinct advantages and disadvantages, making it crucial to choose the right one for your application.

Here’s a quick summary:

- For high-solid content slurries: Electromagnetic flow meters are ideal due to their ability to handle abrasive conditions without clogging.

- For precision measurements in high-density, high-viscosity slurries: Coriolis flow meters offer unmatched accuracy.

- For non-invasive and flexible installation: Ultrasonic flow meters are recommended, especially for retrofitting and applications with minimal downtime.

- For general-purpose, cost-effective solutions: Differential pressure flow meters are a versatile option, although they may require regular maintenance.

Understanding the nature of your slurry and the operational environment is essential for making an informed decision. By aligning your needs with the capabilities of different flow meters, you can achieve accurate measurements, efficient processing, and cost savings.

Leave a comment