A combined heat and power plant in Jiangsu, with an older boiler design, initiated a comprehensive optimization and smart power plant construction project to improve boiler combustion efficiency. Due to the complex and variable composition of the coal used, the company optimized its desulfurization equipment and process flow to meet the requirements of the “Water Pollution Prevention and Control Action Plan” and the “Implementation Plan for Pollutant Discharge Permit System,” aiming to achieve zero discharge of wastewater.

Application:

Monitoring the flow of desulfurization wastewater in the zero discharge process of a power plant.

Requirements:

The flow meter was required to monitor the discharge of desulfurization wastewater, with a need for corrosion resistance, accuracy, and stable performance to ensure precise measurement.

Solution:

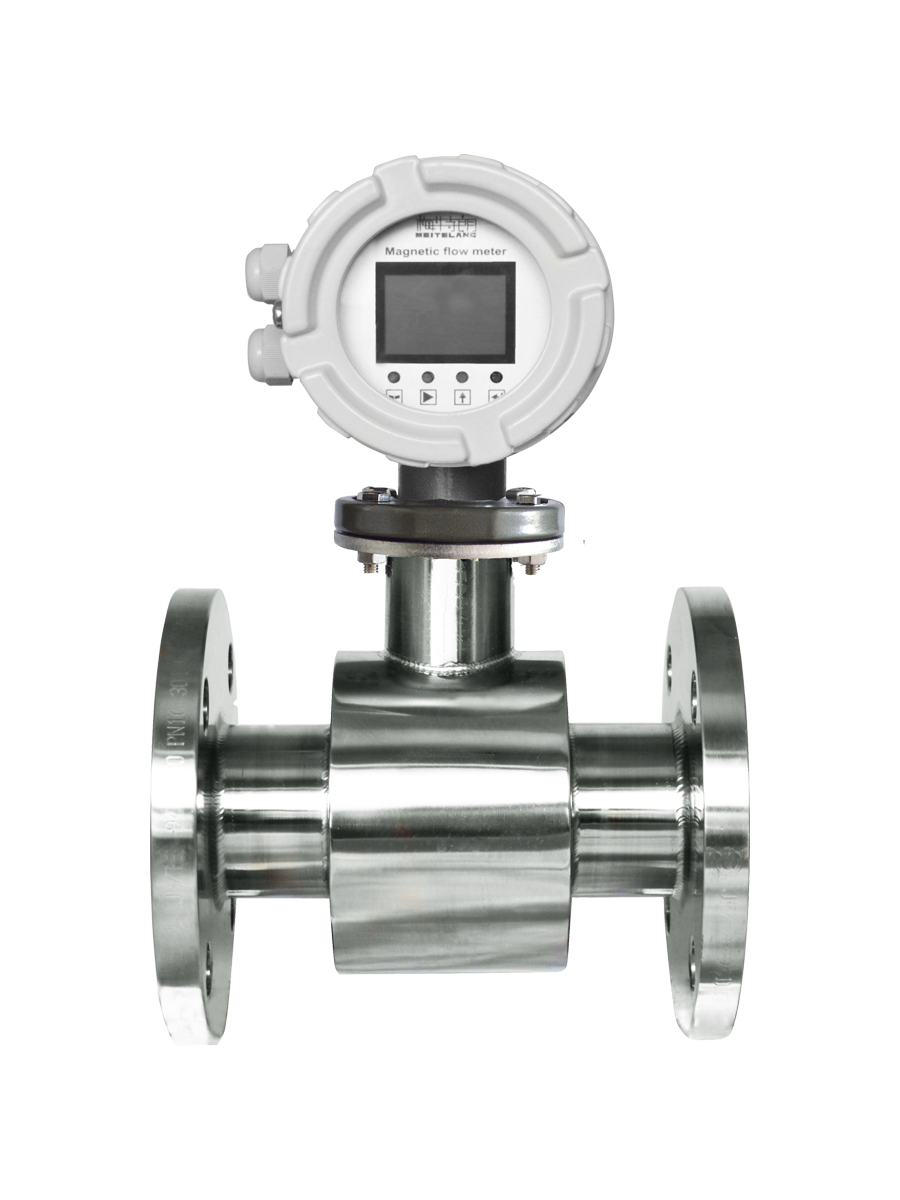

Magnetic Flow Meter for Water and Wastewater (MTF-W), Explosion-Proof

Measurement Requirements

The typical process for desulfurization wastewater treatment at the power plant is “pretreatment + concentration reduction + final solidification.” The wastewater is first pretreated, then concentrated, and finally, the concentrated wastewater undergoes solidification. Due to the small volume of desulfurization wastewater at this plant, the treated wastewater is directly subjected to flue gas evaporation for solidification. Flow meters are required between these two stages to measure the flow of desulfurization wastewater entering the drying tower, providing data support for the regulation of desulfurization equipment operation and ensuring effective desulfurization. The power plant maintains a stable online flow of approximately 0.5t/h of desulfurization wastewater through a DN10 pipeline. The flow meter must be corrosion-resistant, accurate, and stable in performance.

Metlan Solution

Through communication with the customer, it was understood that three flow meters were required, all with the same function, to monitor the volume of wastewater discharged after desulfurization. The flow meters were to be positioned between the desulfurization unit and the drying tower. Despite the removal of large particulate matter, calcium and magnesium hardness ions, and some heavy metal ions in the pretreatment stage, the wastewater still contains heavy metals and chloride ions, making it highly corrosive and requiring high corrosion resistance for equipment and pipeline materials. Therefore, Metlan recommended electromagnetic flow meters with anti-corrosion and explosion-proof features.

Products used

Product Features:

- Suitable for measuring conductive liquids, especially ideal for wastewater, chemical liquids, drinking water, and other media.

- Accuracy levels of 0.5 and 0.2.

- Custom diameter range from DN6 to DN3000

- Explosion-proof function with protection ratings of IP65, IP67, and IP68.

- Multiple communication options available, including RS485, HART, and others.

- Liner: Polyurethane (PU), Neoprene, Polytetrafluoroethylene (PTFE), and others upon request.

- Electrodes: 316L, Hastelloy, Tantalum (Others on request)

Benefits

Improved Accuracy & Calibration:

Metlan electromagnetic flow meters offer high accuracy with a standard tolerance of ±0.5%. For specific customer needs, we can achieve accuracy as precise as ±0.2%, compared to the typical market accuracy range of 3-5%. Additionally, unlike others, our flow meters are individually calibrated and assigned a unique serial number linked to their calibration data. The calibration process follows the national standard JJG 164-2000 to ensure reliability and precision.

Customization:

Our flow meters can be tailored to meet specific working conditions and environmental requirements, including lining, electrodes, and other components. We can also customize the housing, language, nameplates, and more, according to customer requirements. With over 20 years of experience providing OEM services for international brands, we are well-equipped to offer personalized solutions.

Customer Feedback

The customer reported that since the installation of these three electromagnetic flow meters, the performance has been stable and measurements accurate. The precise measurement data allows the plant to quickly respond and adjust the operation parameters of the desulfurization equipment, ensuring optimal desulfurization results and significantly improving production efficiency. Furthermore, the customer highly appreciated the technical support and solutions provided by the Metlan customer service team during the selection, installation, and commissioning phases.

Leave a comment