Flow meters play a crucial role in industries such as oil and gas, pharmaceuticals, food and beverage, and water treatment by ensuring accurate fluid measurement. Over time, various factors can impact a flow meter’s accuracy, making calibration an essential process to maintain its reliability.

In this guide, we will explore what flow meter calibration is, its significance, the difference between calibration and recalibration, common calibration methods, and the factors that affect calibration accuracy.

What is Flow Meter Calibration?

Flow meter calibration is the process of verifying and adjusting the measurement accuracy of a flow meter by comparing its readings to a known standard. This process ensures that the flow meter provides precise measurements that comply with industry regulations and standards.

Key Aspects of Flow Meter Calibration:

- It involves using a reference flow standard to compare actual measurements.

- The flow meter is tested under controlled conditions to determine its accuracy.

- If discrepancies exist, adjustments are made to align the meter with the correct values.

- Calibration must follow certified standards such as ISO, NIST, or national metrology institutes.

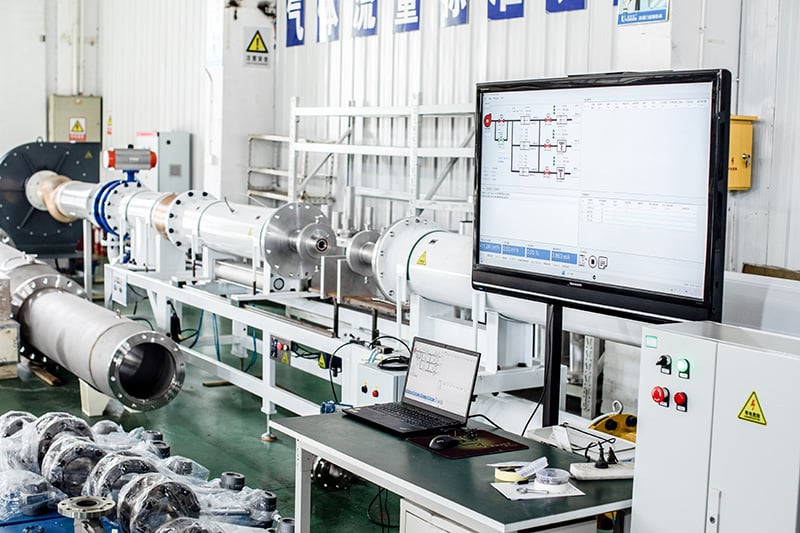

Calibration is typically performed in a laboratory setting or on-site, depending on the type of flow meter and the application.

Significance of Calibration in Flow Meters

Regular calibration of flow meters is critical for maintaining accurate measurements, ensuring regulatory compliance, and optimizing operational efficiency. Below are some key reasons why calibration is necessary:

1. Ensures Measurement Accuracy

Flow meters can drift over time due to environmental conditions, mechanical wear, or fluid properties, especailly low flow flow meters. Calibration ensures the meter provides precise and reliable readings.

2. Compliance with Industry Standards

Many industries, such as pharmaceuticals, food and beverage, and energy, require strict compliance with national and international metrology standards. Regular calibration helps businesses meet ISO, NIST, and legal metrology requirements.

3. Prevents Financial Losses

Inaccurate flow measurements can lead to overbilling or underbilling, which may result in financial losses. Proper calibration ensures correct invoicing and accurate resource allocation.

4. Enhances Process Efficiency

For industries relying on process control, calibration ensures that the correct volume of fluid is being used, improving overall efficiency and productivity.

5. Increases Equipment Longevity

Regular calibration can help detect issues early, preventing unexpected failures and extending the life of the flow meter.

Flow Meter Calibration vs. Recalibration

Although the terms calibration and recalibration are often used interchangeably, they have different meanings.

1. Flow Meter Calibration (Initial Calibration)

- Occurs when the flow meter is first installed or before use.

- Ensures that the meter is delivering accurate readings from the start.

- Often performed by the manufacturer or a certified laboratory.

2. Flow Meter Recalibration

- Refers to the periodic re-verification of a meter’s accuracy over time.

- Necessary due to wear and tear, changes in process conditions, or environmental factors.

- Can be performed on-site or by sending the meter to a certified calibration facility.

When Should a Flow Meter Be Recalibrated?

- After a specific operational period (e.g., every 6-12 months).

- If the meter is exposed to harsh environments or extreme temperatures.

- When there is a noticeable discrepancy in measurement results.

- After maintenance, repairs, or part replacement.

Common Flow Meter Calibration Methods

Several methods are used to calibrate flow meters, each suited for different types of meters and applications. Below are the most commonly used flow meter calibration techniques:

1. Gravimetric Method (Weighing Method)

- Involves measuring the actual mass or volume of fluid that passes through the meter over a given time. Gravimetric calibration is one of the most accurate and cost-effective volumetric and mass flow meter calibration procedures.

- The collected fluid is weighed, and the measurement is compared with the flow meter reading.

- Commonly used for high-accuracy liquid flow meter calibration.

Pros:

- Highly accurate

- Ideal for low and high-flow applications

Cons:

- Requires specialized weighing equipment

- Not suitable for gaseous fluids

2. Volumetric Method

- Similar to the gravimetric method, but instead of measuring mass, the volume of fluid is measured in a calibrated container.

- Used in industries such as water treatment and food processing.

Pros:

- Simple and effective for liquids

- Does not require high-tech equipment

Cons:

- Less accurate for gases

- Can be affected by temperature and pressure variations

3. Master Meter Method

- A highly accurate reference flow meter (Master Meter) is placed in series with the flow meter under calibration.

- Readings from both meters are compared, and adjustments are made accordingly.

- Suitable for both liquid and gas flow meters.

Pros:

- Fast and easy to implement

- Can be done in the field (on-site calibration)

Cons:

- Master meter must be periodically recalibrated

- Accuracy depends on the quality of the master meter

4. Piston Prover Method

- Uses a piston mechanism to push a known volume of fluid through the flow meter.

- Commonly used for high-precision calibration in industries like oil & gas.

Pros:

- Highly precise

- Reliable for both low and high viscosities

Cons:

- Expensive and requires specialized equipment

- Limited to specific flow ranges

Factors Affecting Flow Meter Calibration

Flow meter calibration accuracy can be affected by several external and operational factors:

1. Temperature and Pressure Variations

- Changes in fluid temperature and pressure can alter its density and viscosity, affecting flow measurement.

- Solution: Calibrate under the actual operating conditions or apply compensation formulas.

2. Fluid Properties

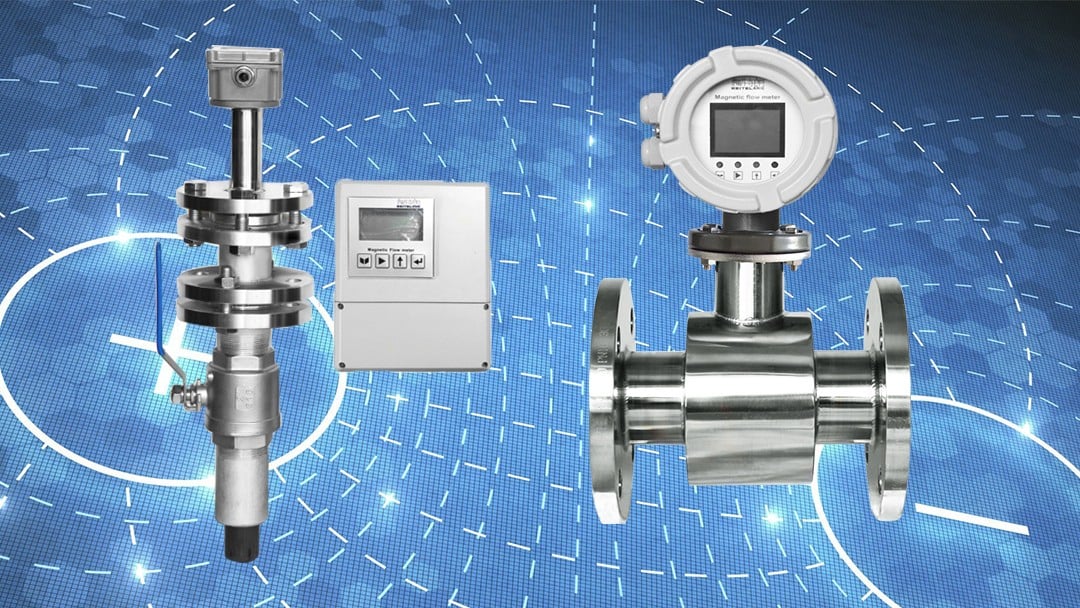

- Different fluids have different viscosities, densities, and conductivity.

- Some meters (e.g., electromagnetic flow meters) require a minimum conductivity level to function properly.

- Solution: Select the right calibration fluid matching the process fluid.

3. Wear and Tear of Meter Components

- Over time, mechanical wear can affect turbine blades, sensors, and internal components.

- Solution: Regular maintenance and recalibration prevent accuracy loss.

4. External Vibrations and Installation Issues

- Poor installation or exposure to vibrations can lead to incorrect readings.

- Solution: Follow manufacturer installation guidelines and use proper mounting techniques.

5. Calibration Frequency

- Too long a gap between calibrations may result in measurement drift.

- Solution: Establish a regular calibration schedule based on industry standards.

Flow meter calibration is a critical process that ensures accurate, reliable, and efficient flow measurement. By understanding the importance of calibration, the different methods available, and the factors that influence calibration accuracy, industries can optimize their processes and maintain compliance with industry standards.

If you’re using flow meters in critical applications, always ensure they are calibrated by certified professionals at regular intervals. Whether it’s initial calibration or recalibration, accurate flow measurement can significantly impact operational efficiency, product quality, and cost savings.

By choosing the right calibration method and following best practices, you can extend the life of your flow meters and maintain precision in every measurement.

Leave a comment