A mining company faces high pressure, strong corrosive conditions, and a complex operating environment during its slurry production process. Accurate and reliable slurry flow measurement is required to ensure the stability and optimization of the production process. The slurry contains solid particles and chemically corrosive components, which place high demands on the material and performance of the flow meter.

Application:

Monitoring the flow in the mining company’s slurry production process

Requirements:

- Real-time monitoring of slurry flow to ensure measurement accuracy.

- A high-pressure, corrosion-resistant, explosion-proof flow meter.

Measurement Specific Requirements

- Pressure Resistance: The fluid pressure in the slurry transport pipeline is relatively high (around 10 MPa), requiring the electromagnetic flow meter to have sufficient pressure resistance.

- Explosion-proof Performance: As the mining environment may pose explosion risks, the equipment must be designed with explosion-proof features.

- Corrosion and Wear Resistance: Slurry often contains solid particles and chemically corrosive components (such as sulfides and metal oxides), requiring the flow meter’s liner and electrodes to have excellent corrosion resistance and wear resistance.

- Anti-Interference Ability: Due to the complex operating environment in the mine, the electromagnetic flow meter must have strong electromagnetic interference resistance to ensure stable data.

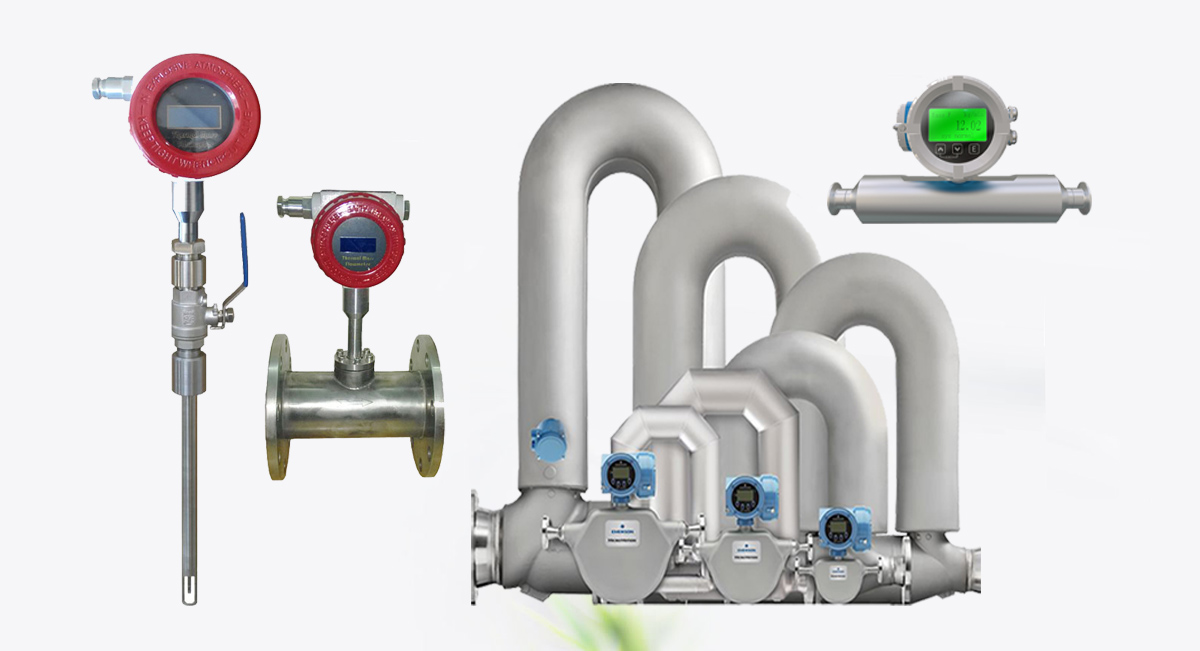

Metlan Solution

After in-depth communication with the customer, a solution was selected that includes an electromagnetic flow meter with high-pressure resistance, explosion-proof functionality, and excellent corrosion resistance. The chosen flow meter is equipped with special materials for the liner and electrodes, ensuring it can withstand the wear from solid particles and corrosion from chemical substances in the slurry. Additionally, the design complies with explosion-proof requirements to meet the high safety standards of the mining site.

Product used

The MTF-S is an mag meter for a wide range of standard process applications with aggressive and abrasive liquids, especially the slurries. It enables reliable flow measurement even under harsh process conditions with temperatures up to +180°C / +356°F, low conductivity (≥5 µS/cm) and solid content.

Product Highlights

- Accuracy: ±0.5 %, Optional: ±0.2%

- Max. Process Pressure: 10 MPa

- Liner: Perfluoroalkoxy alkane (PFA), offering excellent wear resistance and corrosion resistance. Alternative liner materials can be selected based on the specific properties of the measured medium to ensure optimal performance.

- Electrode Configuration:

When measuring slurry or similar fluids, the electrodes are prone to deposit buildup. Contamination of the electrodes may cause the instrument to malfunction. To prevent electrode contamination, electrodes with shapes that resist deposit buildup, such as pointed or hemispherical electrodes, can be selected. Alternatively, scraper-type electrodes can be used, allowing manual cleaning of deposits from the sensor exterior. - Explosion-proof.

Conclusion

By adopting Metlan’s electromagnetic flow meter, the customer achieved accurate, real-time monitoring of slurry flow, ensuring stability and optimization of the production process. In a high-pressure, complex, and corrosive working environment, the reliability and long lifespan of the equipment helped the customer reduce maintenance costs and improve production efficiency. The explosion-proof design also ensured the safety of the mining site, providing the customer with a complete and trustworthy flow measurement solution.

Leave a comment