A new materials technology company is expanding its production facility for a series of pyrrolidone-based products. The main construction components include catalyst preparation units, α-pyrrolidone units, and N-vinylpyrrolidone (NVP) units. The project’s public utilities, including water supply, power, heating, and cooling circulation water, will rely on the existing infrastructure at the plant.

Application:

Flow Meters in the Pyrrolidone Series Product Production Project

Requirements:

The project requires high-precision, maintenance-free, explosion-proof flow meters for various gases and fluids in the pyrrolidone production process.

Measurement Requirements

The project requires flow meters to accurately measure the following systems: α-pyrrolidone units, drying workshops, N-vinylpyrrolidone (NVP) units, power workshops, external lines, as well as low-pressure steam, medium-pressure steam, high-pressure steam, thermal oil, ammonia water, hot water, circulating water, chilled water, sodium hypochlorite, and fire water. The pipe diameters range from DN20 to DN100. The flow meters must provide high precision and stability, with certification from high-precision flow calibration devices before leaving the factory to ensure accuracy. Additionally, the flow meters must be maintenance-free.

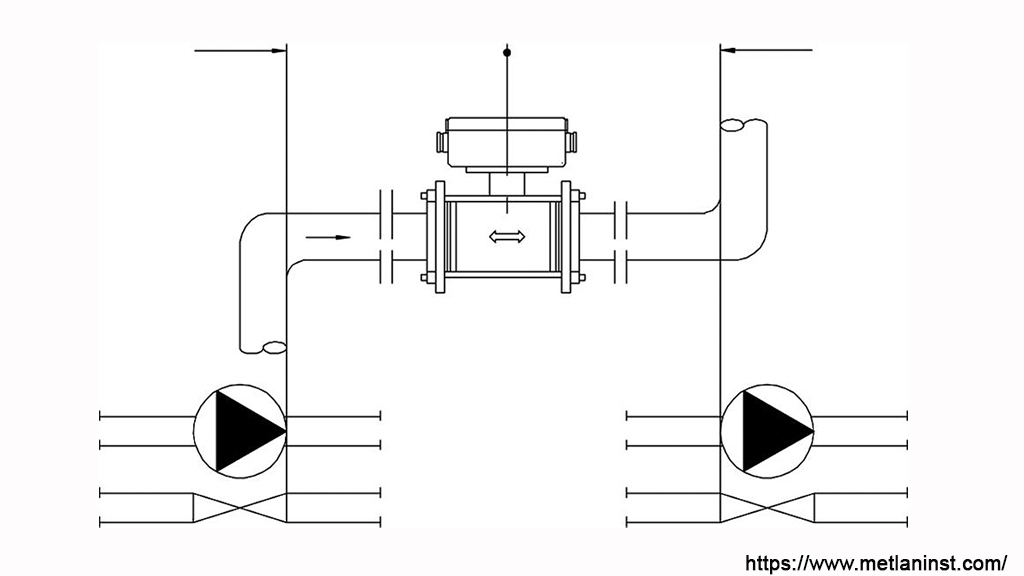

Metlan Solution

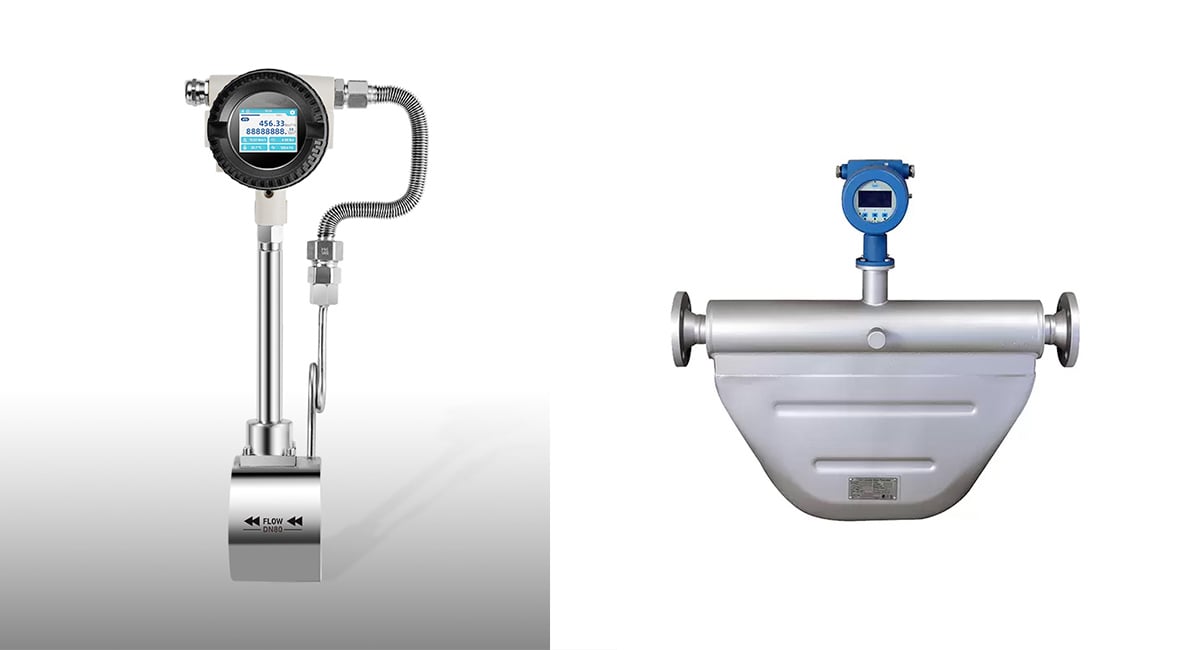

After consultation with the Metlan selection engineering team, integrated temperature and pressure-compensated vortex flow meters were selected for measuring steam, nitrogen, and thermal oil. For the measurement of chilled water, circulating water, and NVP solution in the drying area, vortex flow meters without temperature and pressure compensation were chosen. All vortex flow meters are equipped with explosion-proof features, rated to IP65 protection, and constructed with 304 stainless steel bodies and 316 probes, meeting the customer’s maintenance-free requirements.

Metlan Voterx Flow Meter

- Measuring Medium: Steam, gas, liquid (avoid multiple-direction fluid)

- Accuracy: Liquid: 1.0%, Gas: 1.5%

- Repeatability: Liquid: 0.33%, Gas: 0.5%

- Flow Range: Liquid: 0.7 m/s to 7 m/s, Gas: 7 m/s to 40 m/s

- Working Pressure: Standard: 1.6 MPa, Optional: 2.5 MPa to 4.0 MPa (on request)

- Fluid Temperature: Common type: -40°C to 250°C, High-temperature type: 100°C to 350°C

- Body Material: 304 Stainless Steel (SS316 optional)

- Ambient Temperature: -35°C to 60°C (without LCD), -5°C to 60°C (with LCD)

- Relative Humidity: 5% to 95%

- Protection Level: IP65

- Explosion-proof: Optional

For the measurement of conductive liquids such as ammonia water, hot water, and circulating water in the α-pyrrolidone units, Metlan selected explosion-proof electromagnetic flow meters, equipped with PTFE and rubber liners and tantalum or 316L electrodes, to ensure compatibility with the acidic or alkaline nature of the media.

Magnetic Flow Meter for Water and Wastewater (MTF-W)

Features:

Improved Accuracy:

Metlan electromagnetic flow meters have an accuracy of 0.5%, whereas flow meters on the market typically have an accuracy between 3-5%. Based on customer requirements, we can achieve an accuracy of 0.2%. Each flow meter is calibrated and assigned a unique serial number corresponding to all calibration data. The calibration equipment meets the national standard JJG 164-2000.

Customization

- PU, Neoprene, or PTFE liners for excellent chemical resistance.

- A wide range of electrode materials available.

- Customizable colors and appearance upon request.

- LCD displays available in multiple languages, including English, Spanish, and French, with options for additional languages.

- Custom constructions available to meet specific customer needs.

- Available in both compact and remote transmitter versions.

Magnetic Flow Meter for Water and Wastewater (MTF-W)

Customer Benefits

Since installation, Metlan flow meters have demonstrated high stability. Customer feedback indicates that, regardless of high temperatures, high pressures, or varying media conditions, the instruments maintain precise measurement, significantly reducing maintenance work and improving overall production efficiency. In production areas involving flammable and explosive substances, the explosion-proof design ensures operational safety.

Leave a comment