A biopharmaceutical company in China uses a fermentation process in its erythromycin production line. The process requires the use of glucose solution, nitrogen source solution, culture medium solution, tryptophan solution, and glycerol solution as raw materials for fermentation. Temperature, pressure, concentration, flow rate, flow speed, pH, and liquid level must be monitored throughout the process. The common flow range for these solutions is 30L/h-3m³/h, with a density of 1kg/m³, and the pipe diameters range from DN15 to DN20.

Additionally, the fermentation process often produces foam, requiring the addition of a defoaming agent into the reactor.

Application:

Biopharmaceutical Production Line for Erythromycin

Requirements:

- Precise measurement of raw material addition in the pharmaceutical reactor to ensure accurate dosing.

- Real-time continuous flow control.

- Stable instrument performance that meets hygiene and cleanliness standards.

Solution

Through communication with the customer, it was understood that the fermentation process is a biological process, and the materials used are good culture media for microorganisms. Therefore, it is crucial to ensure that there is no contamination by other microorganisms during production. The customer uses SIP (Steam In Place) sterilization for the fermenter and pipelines, ensuring thorough cleaning and sterilization before inoculation. Consequently, while measuring specific raw materials, the customer requires the equipment to withstand steam sterilization.

To ensure stable operation, Metlan supplied split-type electromagnetic flow meters with a 0.5 accuracy class for measuring glucose solution, nitrogen source solution, culture medium solution, tryptophan solution, and other raw materials. For measuring the defoaming agent in the main pipeline, a Coriolis mass flow meter was selected. Temperature, pressure, and other related instruments were also provided.

Products used

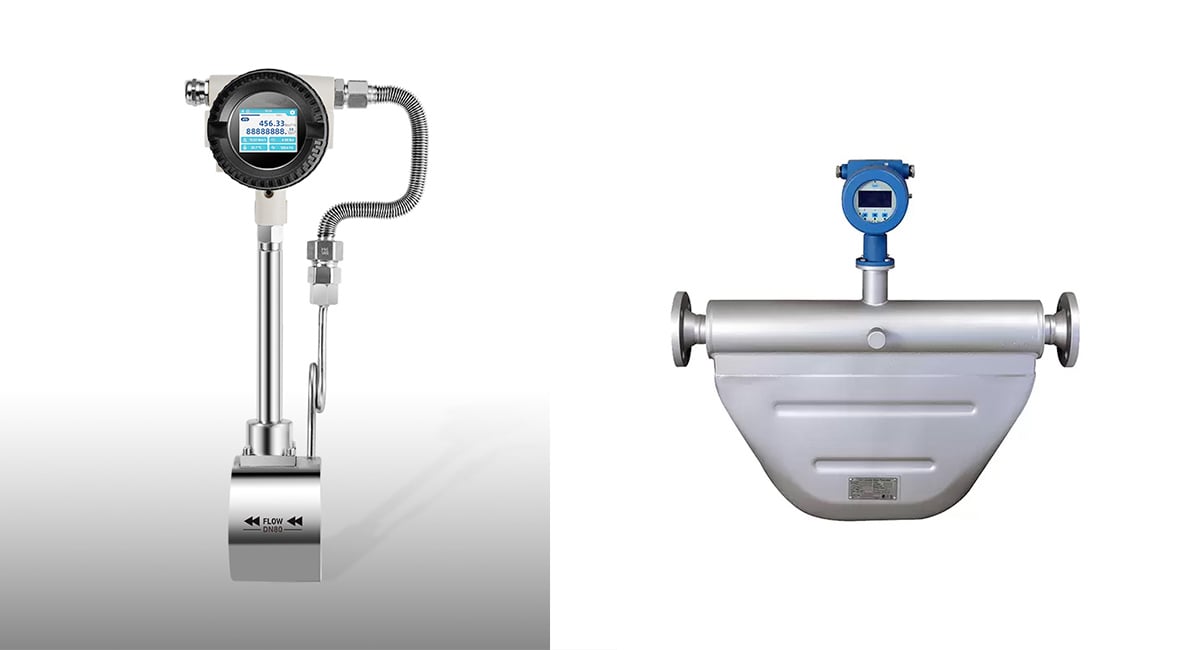

Remote Electromagnetic Flow Meter (MTF-F-200)

MTF-F-200 is the remote version of MTF-F-100 eletromagnetic flow meter that provides a wide options of wetted materials and medium temperature ranges up to 180 °C/356 °F, to maximize installation flexibility and operational safety in demanding environments.

- Accuracy: Standard ±0.5 %, Optional ±0.2 %

- Measuring Range: 0.3 m³/h to 125000 m³/h

- Medium Temperature Range

PU:0 to 140°F (-18 to 60°C)

Neoprene:-13°F to 176°F (-25°C to +80°C)

IR:-13°F to 176°F (-25°C to +80°C)

FEP:-13 to 300°F (-25 to 150°C)

PTFE:-13 to 300°F (-25 to 150°C)

ETFE:-40 to 356°F (-40 to 180°C)

PFA:-40 to 356°F (-40 to 180°C) - Max. Process Pressure: 100 bar (1450.38 psi)

Coriolis Mass Flow Meters for Advanced Process Applications (MASS-A)

Features:

- Certified for hygienic use

- Supporting CIP or SIP cleaning procedures

- High accuracy mass, density and volume flow measurement

- Also available in customer specific constructions

- English, Spanish, French and other languages on request are available for LCD display.

- Each flow meter is calibrated and assigned a unique serial number corresponding to all calibration data.

Benefits

- Improved Accuracy: Metlan electromagnetic flow meters offer high accuracy with a standard tolerance of ±0.5%, compared to the typical market accuracy range of 3-5%. For specific customer needs, we can achieve accuracy as precise as ±0.2%. Additionally, our Coriolis mass flow meters provide standard accuracy of ±0.5%, with optional accuracies of ±0.2% and ±0.15%.

- Calibration: Each flow meter is individually calibrated and assigned a unique serial number linked to its calibration data. The calibration process complies with the national standard JJG 164-2000 to ensure reliability and precision.

- Customization: Our flow meters can be tailored to meet specific working conditions and environmental requirements, ensuring stable and reliable performance in various operational settings.

Customer Feedback

Since the introduction of Metlan’s instruments, the solution has seamlessly matched the pipeline design. The equipment has ensured accurate metering and efficient control of raw material injection, helping improve the stability and reliability of the biological fermentation process. This has resulted in higher product quality and yield. Additionally, Metlan’s flow instruments are easy to maintain, with a compact design and simple operation, reducing the daily maintenance burden and lowering overall usage costs.

Leave a comment