Client Industry:

Municipal Wastewater Treatment

Challenge:

Measuring large flows with high accuracy and fluctuating flow rates

Solution:

Custom 6-Electrode DN600 Magnetic Flow Meter

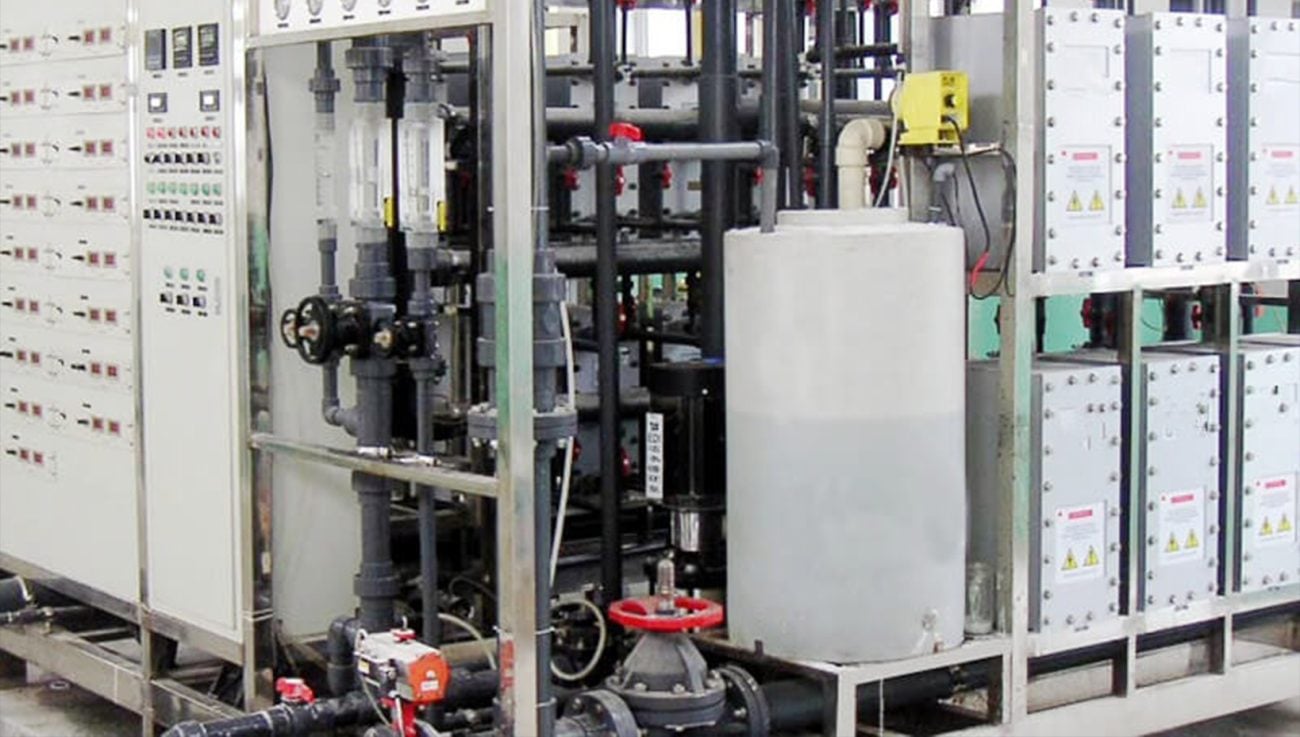

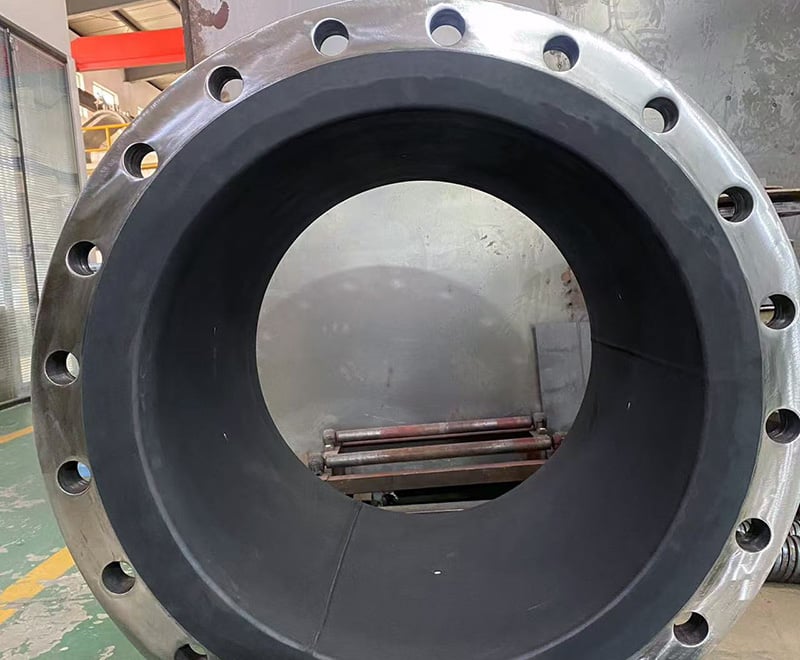

A wastewater treatment plant required a high-precision flow measurement solution for monitoring large-volume effluent discharge. After detailed consultations, Metlan Instruments designed a custom DN600 electromagnetic flow meter (EMF) with a 6-electrode configuration and a chloroprene rubber (CR) liner, tailored to the client’s abrasive, particle-laden wastewater conditions. The solution ensured accuracy across varying flow rates while addressing durability challenges.

Client Background

- Industry: Municipal Wastewater Treatment

- Application: Effluent discharge monitoring

Challenges

Measuring large flows with high accuracy, despite:

- Fluctuating flow rates.

- Highly abrasive, solid-laden wastewater.

Solution: 6-Electrode DN600 Magnetic Flow Meter

Metlan Instruments engineers developed a multi-electrode mag meter with the following features:

Electrode Configuration:

- Bottom Electrode (Grounding):

- Ensures stable signal grounding in low-conductivity conditions.

- Reduces electrical noise from fluid variability.

- Top Electrode (Full-Scale Measurement):

- Optimized for high-flow scenarios (>80% capacity).

- Dual Electrodes (Left & Right Sides):

- Lower Pair: Positioned near the pipe centerline for low-flow precision (<30% capacity).

- Upper Pair: Activated during mid-to-high flows for seamless measurement across the full range.

Client Feedback

“The 6-electrode design eliminated our low-flow measurement gaps, and the chloroprene rubber liner has held up remarkably against the abrasive sludge.”

– Plant Operations Manager

Relate Post: Magnetic Flow Meter Selection Guide