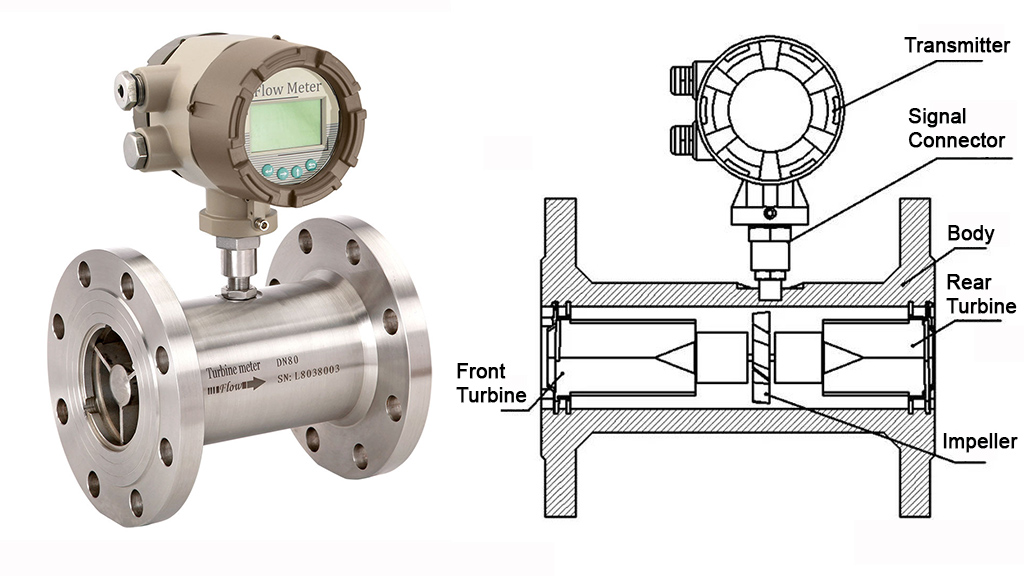

The turbine flow meter plays a critical role in volumetric control. In industrial production, volumetric control significantly reduces labor costs, while also enhancing the accuracy and controllability of the production process.

What is volumetric control?

A volumetric control system consists of components such as a flow meter, volumetric controller, solenoid valve, and control unit. It enables precise control over fluid measurement, filling, and batching processes.

Upon receiving the signal from the flow meter, the volumetric controller accumulates and displays the data. The required control value is set within the control unit. Once the accumulated value reaches the set target, the controller outputs a switch signal. This signal is used to activate a relay or contactor to control the shut-off device installed in the pipeline, thereby achieving the desired volumetric control.

Four steps to easily troubleshoot if the flow meter is not displaying:

- Is the pipeline blocked?

How to check: Verify if fluid is flowing out of the outlet. - Is the turbine converter damaged?

How to check: Remove the converter and use a screwdriver to induce movement of the magnetic field at the base, then check if the flow meter displays flow. - Is the flow meter’s impeller stuck?

How to check: Confirm if the impeller is rotating.

Solution: Disassemble and clean the impeller. - Be aware of the flow limits:

Turbine flow meters provide accurate readings within their specified measurement range. If the flow rate is below the lower limit, it may fail to register or display a reading.

Leave a comment