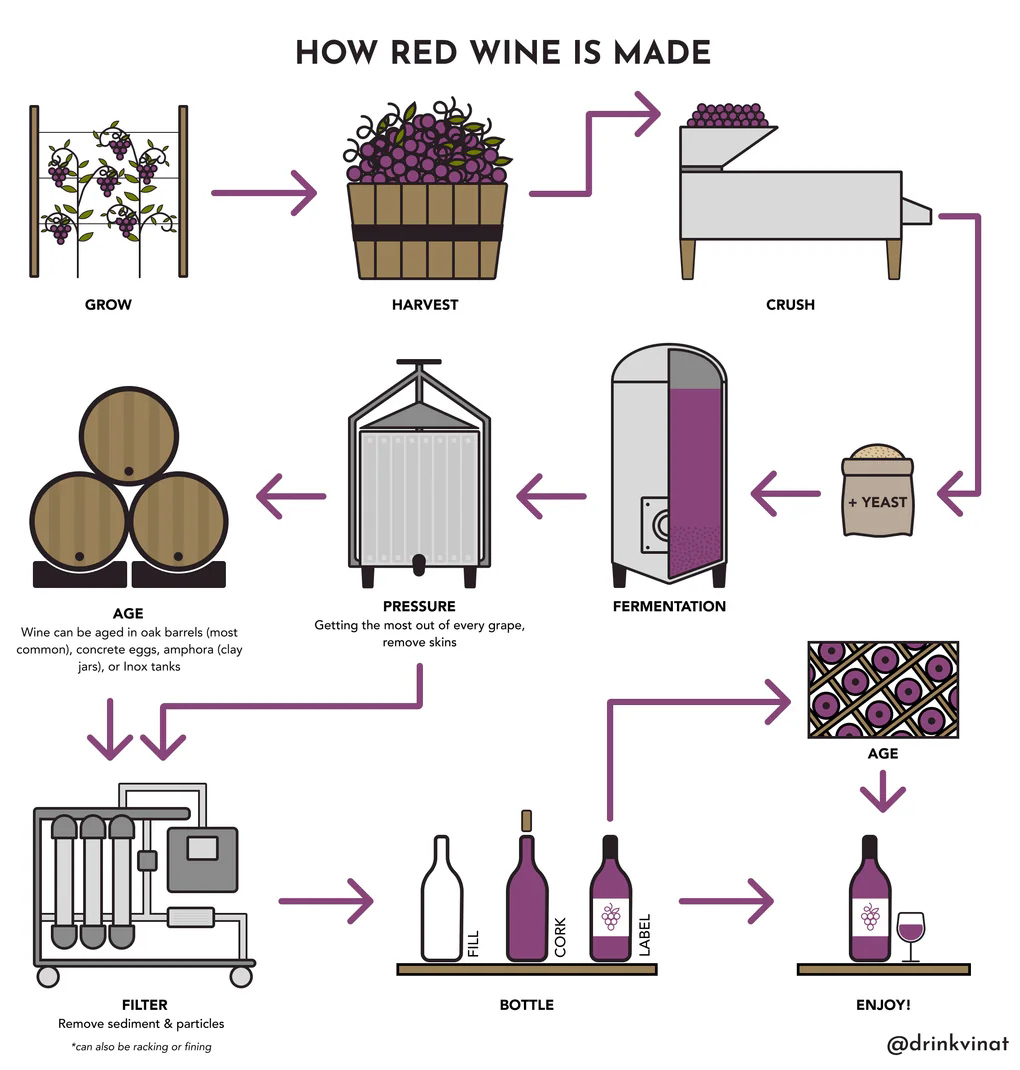

The wine production process involves several key stages, with the filling process directly affecting the final product quality and yield. The accuracy, hygiene, and stability of flow measurement in the filling process are crucial to product consistency and production efficiency.

Traditional flow meters have certain limitations in terms of measurement accuracy, cleanliness, and long-term operational stability, especially in food-grade production environments like wine production, where flow meters must meet stringent food safety standards. With the advancement of automated production lines, the requirements for flow measurement have become even more demanding, requiring flow meters to not only offer high precision and stability but also meet hygiene and safety standards to prevent contamination of the wine.

Application:

Red wine bottling flow control

Looking for a precise flow measurement instrument

to accurately control dosing volume and detect potential leaks.

Measurement requirements

The client is a well-known wine producer facing the following challenges:

- Precise Flow Control: In the filling process, flow must be precisely controlled to ensure each bottle is filled consistently, avoiding overfilling or underfilling, which can impact product quality and production efficiency.

- Compliance with Food Safety Standards: Since wine is a food product, all equipment that comes into contact with the liquid must comply with food-grade safety standards to avoid contamination by harmful substances.

- Increased Production Efficiency: The client aims to upgrade its production line with automation to improve efficiency, reduce manual labor, and minimize human error.

- Durability and Easy Maintenance: Given the high frequency of use, the flow meter needs to be durable and easy to maintain, reducing cleaning and maintenance work.

Our Solution

To address the challenges faced by the client in the wine filling process, we provided a solution based on food-grade electromagnetic flow meters, detailed as follows:

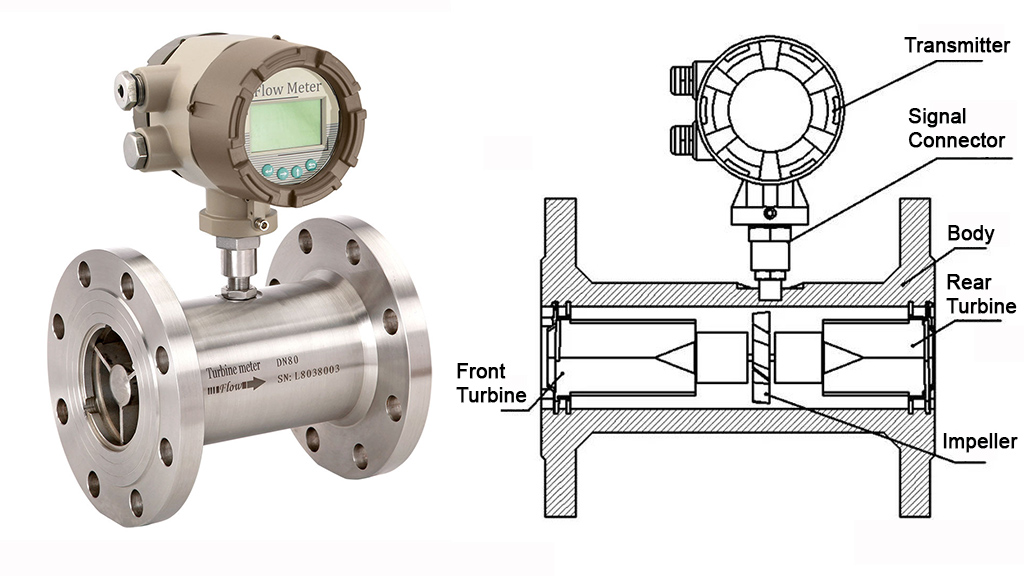

- Precise Flow Control: We implemented high-precision food-grade electromagnetic flow meters capable of accurately measuring the flow of wine to ensure consistent filling. The flow meter operates based on Faraday’s law of electromagnetic induction, making it suitable for measuring the flow of conductive liquids (such as wine), with strong anti-interference capabilities and stability. It provides exceptional measurement accuracy and is unaffected by changes in temperature, pressure, or viscosity, making it ideal for precise control of wine flow.

- Food Safety Standards & PFA Liner Design: The electromagnetic flow meter uses food-grade materials like 304 or 316L stainless steel, compliant with FDA and EU food contact materials standards. All wetted parts are polished to a mirror finish, preventing the attachment of contaminants and ensuring the purity of the wine. Additionally, the flow meter is equipped with a PFA (Perfluoroalkoxy) liner, which offers exceptional chemical resistance and high-temperature resistance, effectively preventing the wine from coming into contact with metal parts, thus avoiding contamination. The design also meets EHEDG certification requirements.

- Increased Production Efficiency: The electromagnetic flow meter works in conjunction with the wine filling machine, providing real-time flow data that enables the automated filling system to adjust the flow rate and ensure consistent filling volumes for each bottle. This integration reduces manual intervention, minimizes human error, and enhances production efficiency. The system’s intelligent data processing capabilities allow the flow meter to interface with the filling machine’s control system (PLC or SCADA), ensuring the precise control of filling speeds and optimal performance.

- Durability & Low Maintenance: With no moving parts, the electromagnetic flow meter is highly durable and stable, even in high-frequency operations. The modular design simplifies cleaning and maintenance, reducing production downtime. The client only needs to periodically calibrate and inspect the equipment to ensure long-term stable operation.

Products used

Sanitary Magnetic Flow Meters (MTF-A)

MTF-A is the preferred electromagenetic flow meter for hygienic applications in the food and beverage and life sciences industries. It is easy to install and take apart, supporting CIP or SIP cleaning procedures, and available with compact or remote version of transmitter.

Conclusion

By adopting food-grade electromagnetic flow meters with PFA liner design, we provided the client with a precise, hygienic, and efficient solution that successfully addressed flow control challenges in the wine filling process while meeting high food safety and production efficiency requirements. The solution not only improved the automation level of the production line but also ensured consistent filling volume and product quality, helping the client enhance overall production capacity and reduce potential errors and losses during production.

Leave a comment