Benzin ist das Lebenselixier der Transport- und Kraftstoffindustrie. Es treibt Fahrzeuge, Maschinen und Generatoren auf der ganzen Welt an. Denn Benzin ist leicht entzündlich, flüchtig und wirtschaftlich wertvoll, seinen Durchfluss genau und sicher zu messen ist in Branchen wie der Petrochemie, dem Kraftstoffvertrieb und dem Tankstelleneinzelhandel ein wichtiges Thema.

Dies ist der Ort, an dem Benzindurchflussmesser ins Spiel kommen. In diesem umfassenden Leitfaden erfahren Sie alles, was Sie über Benzin als Flüssigkeit und seine Eigenschaften wissen müssen, was Benzindurchflussmesser sind, welche Typen für Benzinanwendungen empfohlen werden und vor allem, wie Sie das richtige Gerät für Ihren speziellen Anwendungsfall auswählen.

Inhaltsübersicht

Top 5 der empfohlenen Öldurchflussmessgeräte

Was ist Benzin?

Benzin, in vielen Teilen der Welt auch als Petrol bekannt, ist ein transparente, aus Erdöl gewonnene Flüssigkeit wird hauptsächlich als Kraftstoff in Verbrennungsmotoren verwendet. Es entsteht bei der fraktionierten Destillation von Rohöl und wird mit Zusatzstoffen angereichert, um die Leistung zu verbessern, die Emissionen zu verringern und das Klopfen des Motors zu verhindern.

Hauptmerkmale von Benzin:

- Leicht entflammbar: Benzindämpfe können sich leicht entzünden und stellen ein erhebliches Explosionsrisiko dar.

- Flüchtig: Benzin verdampft schnell, was die Eindämmung und Messung erschwert.

- Niedrige Viskosität: Normalerweise etwa 0,5-0,8 Centipoise bei 20°C.

- Dichte: Etwa 0,71-0,77 kg/L je nach Mischung und Zusatzstoffen.

- Temperatur-Empfindlichkeit: Das Volumen des Benzins kann sich bei Temperaturschwankungen erheblich ausdehnen oder zusammenziehen.

- Kohlenwasserstoff-Zusammensetzung: Eine Mischung aus Alkanen, Cycloalkanen und aromatischen Kohlenwasserstoffen.

Diese Eigenschaften wirken sich direkt darauf aus, wie Benzin gelagert, gehandhabt und gehandelt werden sollte. gemessen.

Was ist ein Benzindurchflussmesser?

A Benzindurchflussmesser ist ein Gerät zur Messung des Volumens oder der Masse von Benzin, das durch eine Rohrleitung oder ein Schanksystem fließt. Diese Zähler sind unerlässlich für:

- Fuel dispensing at gas stations

- Kraftstofflieferwagen und Tankwagen

- Industrielle Prozesssteuerung

- Verwaltung der Kraftstoffbestände

- Depotübertrag und Rechnungsstellung

Da Benzin flüchtig und gefährlich ist, muss der Durchflussmesser nicht nur genau und wiederholbarsondern auch explosionsgeschützt, korrosionsbeständigund verträglich mit Kohlenwasserstoffen.

Empfohlene Benzindurchflussmesser-Typen

Aufgrund der Entflammbarkeit und der chemischen Zusammensetzung von Benzin sind nicht alle Durchflussmessgeräte für Benzin geeignet. Hier sind die am häufigsten verwendeten Technologien:

1. Durchflussmessgeräte mit positiver Verdrängung (PD)

Am besten geeignet für: Kraftstofflieferwagen, eichpflichtiger Verkehr, hochpräzise Zapfanlagen

Wie es funktioniert: PD-Zähler fangen feste Benzinmengen auf und zählen die Anzahl der Füllungen und Entleerungen der Kammer.

Vorteile:

- Sehr hohe Genauigkeit (±0,1-0,5%)

- Gut für niedrige und mittlere Durchflussraten

- Erfordert keine geraden Rohrführungen

Beschränkungen:

- Bewegliche Teile können mit der Zeit verschleißen

Empfohlene PD-Durchflussmessgeräte für Benzin:

Birotor Hochpräzisions-PD-Durchflussmesser mit mechanischem Zähler:

- Hohe Genauigkeit bis zu ±0,1 %.

- Explosionsschutzklasse: Ex db IIC T6 Gb

- Stabiler Lauf mit tiefer Stimme.

- Gute Entstörungsleistung und lange Nutzungsdauer.

- Starke Anwendbarkeit bei Viskositätsänderungen.

- Hochpräzise Messung mit einer Genauigkeit von bis zu ±0,2%.

- Explosionsschutzklasse: Ex db IIC T6 Gb.

- Nicht empfindlich gegenüber Viskositätsänderungen.

- Einfache Installation, ohne dass gerade Rohrleitungen erforderlich sind.

- Unterstützt die Kommunikationsprotokolle HART und RS485

Getriebe-Durchflussmesser mit positiver Verdrängung:

- Konzipiert für Flüssigkeiten mit geringem Durchfluss ab 0,6 l/h.

- Hochpräzise Messung mit einer Genauigkeit von bis zu ±0,5%.

- Explosionsschutzklasse: Ex db IIC T6 Gb.

- 150:1 breites Turndown-Verhältnis.

- Geeignet für die Messung hochkorrosiver Medien wie Schwefelsäure, Flusssäure und andere aggressive Chemikalien.

2. Coriolis-Massedurchflussmessgeräte

Am besten geeignet für: Präzisionskraftstoffmischung, Kraftstofftests im Labor, High-End-Anwendungen

Wie es funktioniert: Misst den Massendurchfluss direkt über den Coriolis-Effekt; liefert auch Dichte und Temperatur.

Vorteile:

- Äußerst genau (±0,1-0,2%)

- Misst Masse, nicht nur Volumen

- Keine beweglichen Teile

Beschränkungen:

- Hohe Kosten

- Schwerer und sperriger als andere Typen

Coriolis-Massendurchflussmesser:

- Hohe Genauigkeit bis zu ±0,1 %, gute Zuverlässigkeit.

- Explosionsschutzklasse: Ex db IIC T6 Gb.

- Gute Nullpunktstabilität und Antistörungsleistung.

- Keine beweglichen Teile, keine Wartung erforderlich.

- Unterstützt die Kommunikationsprotokolle HART und RS485.

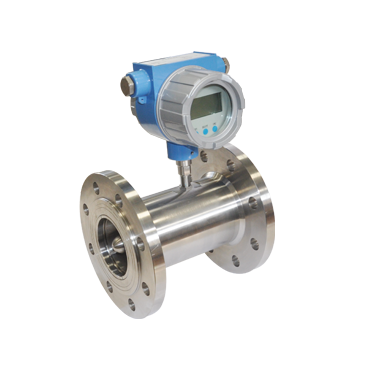

3. Turbinen-Durchflussmessgeräte

Am besten geeignet für: Inline-Kraftstoffmessung in sauberen Systemen, Volumenstrom

Wie es funktioniert: Die Strömung dreht einen Turbinenrotor; die Drehzahl ist proportional zur Durchflussmenge.

Vorteile:

- Gute Genauigkeit (±0,5-1,0%)

- Niedriger Druckverlust

- Schnelle Reaktionszeit

Beschränkungen:

- Empfindlich gegenüber Flüssigkeitsviskosität und Verschmutzung

- Erfordert gerade Rohrlängen

- Hohe Genauigkeit bis zu ±0,2 %, mit guter Wiederholbarkeit.

- Explosionsschutzklasse: Ex db IIC T6 Gb.

- 1:20-Abschaltverhältnis.

- Platzsparende Konstruktion mit einer Mindestbohrung von DN0,5.

Empfohlene Benzindurchflussmessgeräte und Anwendungen

Werfen wir einen genaueren Blick auf wo Benzindurchflussmesser verwendet werden und welche Typen für den jeweiligen Fall am besten geeignet sind:

| Anmeldung | Empfohlener Zählertyp | Wichtige Anforderungen |

|---|---|---|

| Tankstellen | PD-Zähler oder Turbinenradzähler | ATEX-zertifiziert, hohe Genauigkeit, kompakt |

| Tankwagen | Ovalrad-PD-Zähler | Vibrationsbeständig, tragbar, robust |

| Raffinerien | Coriolis-Messgeräte | Hochpräzise, integrierte Dichtemessung |

| Massengut-Terminals | Turbinen- oder PD-Zähler | Große Rohrgrößen, eichpflichtige Genauigkeit |

| Generatoren und Maschinen | PD-Zähler | Kleine Stellfläche, explosionsgeschützt |

| Betankung in der Luftfahrt | Coriolis- oder PD-Messgeräte | Geringes Gewicht, rückführbare Genauigkeit |

Wie man den richtigen Benzindurchflussmesser auswählt

Bei der Wahl eines Benzindurchflussmessers geht es nicht nur darum, das genaueste oder teuerste Gerät auszuwählen. Der Schlüssel ist die Anpassung an Ihre spezifische Anwendung, Sicherheitsanforderungen und Budget. Hier sind die wichtigsten Schritte:

1. Definieren Sie den Zweck

- Benötigen Sie ein Gesamtvolumen für die Rechnungsstellung oder die Bestandsaufnahme?

- Benötigen Sie eine Echtzeit-Durchflussrate für die Prozesssteuerung?

- Werden Sie das Messgerät fest installieren oder mobil verwenden?

2. Bestimmen Sie den Durchflussbereich und die Rohrgröße

Wählen Sie ein Messgerät mit einem Durchflussbereich, der Ihren erwarteten Mindest- und Höchstdurchflüssen entspricht. Eine Über- oder Unterdimensionierung kann die Genauigkeit stark beeinträchtigen.

3. Flüssigkeitseigenschaften beurteilen

Benzinmischungen können je nach Region und Jahreszeit unterschiedlich sein. Kennen Sie die Temperatur, Viskosität und Druck an dem die Flüssigkeit gemessen werden soll.

4. Geeignete Materialien auswählen

Suchen Sie nach Zählern mit Auskleidungen aus Aluminium, rostfreiem Stahl oder PTFE-Materialien, die der Korrosion durch Benzin und chemischen Angriffen widerstehen.

5. Ausgabe und Integration berücksichtigen

Benötigen Sie eine digitale Anzeige? RS485/Modbus-Kommunikation? Impulsausgang? Wählen Sie ein Messgerät, das mit Ihrem Kontrollsystem, Ihrer SPS oder Ihrem mobilen Lesegerät verbunden werden kann.

6. Wartung und Kalibrierung

Wählen Sie ein Design, das Folgendes ermöglicht einfache Reinigung, Inspektion und Neukalibrierung. Einige Messgeräte verfügen über eine Selbstdiagnose oder intelligente Warnmeldungen bei Kalibrierungsabweichungen.

Optionales Zubehör

- Siebe oder Filter: Verhindern Sie, dass Verunreinigungen den Durchflussmesser beschädigen.

- Explosionsgeschützte Gehäuse: Für gefährliche Zonen.

- Durchfluss-Zählwerke: Für die ferngesteuerte oder zentralisierte Durchflussüberwachung.

- Temperatur- und Druckkompensatoren: Für verbesserte Genauigkeit in schwankenden Umgebungen.

- Wird zusammen mit dem Durchflussmesser stromaufwärts installiert, um sicherzustellen, dass die in das Gerät eintretende Flüssigkeit frei von Luft oder Gas ist.

- Entfernt mitgerissene Luft oder Gas aus der Flüssigkeit.

- alle nachgeschalteten Systemkomponenten zu schützen.

- Verhindert Ungenauigkeiten aufgrund von Lufteinschlüssen oder Blasen in der Flüssigkeit, die die Durchflussmessung stören können.

Bewährte Praktiken für die Installation von Benzindurchflussmessern

Um Langlebigkeit und Genauigkeit zu gewährleisten:

- Stellen Sie die Messgeräte nicht in der Nähe von Pumpen oder Ventilen auf, die Turbulenzen verursachen.

- Sorgen Sie für eine gute Erdung, um statische Entladungen zu vermeiden.

- Beachten Sie die Empfehlungen des Herstellers für gerade Rohrlängen.

- Führen Sie nach der Installation immer einen Drucktest durch.

- Prüfen Sie das Messgerät regelmäßig und kalibrieren Sie es bei Bedarf neu.

Die genaue Messung von Benzin ist nicht nur entscheidend für finanzielle Rechenschaftspflicht und Bestandskontrolle, sondern auch für Sicherheit und Einhaltung der Vorschriften. Ganz gleich, ob Sie eine Tankstelle betreiben, ein Ölterminal verwalten oder einfach nur den Kraftstoffverbrauch eines Generators überwachen, der richtige Benzindurchflussmesser kann einen erheblichen Unterschied in Bezug auf Leistung und Zuverlässigkeit ausmachen.

Während Positive Verdrängung und Turbine Durchflussmesser sind nach wie vor die beliebtesten für allgemeine Benzinanwendungen, Coriolis-Massendurchflussmesser sind ideal für hochpräzise oder wissenschaftliche Anwendungen.

Im Zweifelsfall sollten Sie sich an Experten für Durchflussmessgeräte wenden, die Ihnen Lösungen empfehlen können, die auf Ihre Betriebsbedingungen zugeschnitten sind.