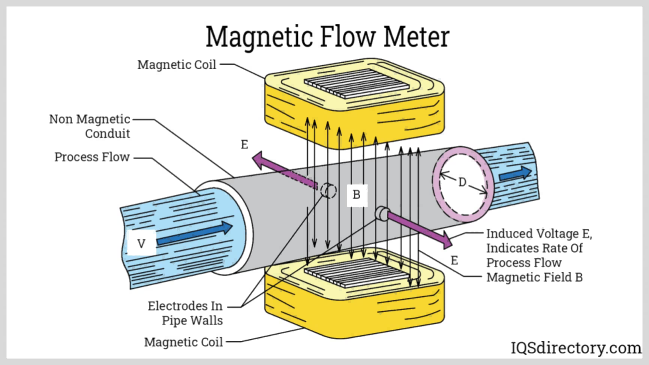

Electromagnetic flowmeters are widely used in industrial applications for flow measurement, particularly in liquids without solid particles. Their accuracy and reliability are crucial in many industries. Selecting the right electromagnetic flowmeter involves considering various factors related to the operating conditions and characteristics of the measured medium. The following are key considerations to help you scientifically select the most suitable electromagnetic flowmeter.

Want to know what a magnetic flow meter is and how it works? Here is a comprehensive guide to magnetic flow meters.

Table of Contents

Understand the Characteristics of the Measured Medium

The operating principle of an electromagnetic flowmeter relies on the conductivity of the medium. The properties of the medium directly affect the flowmeter’s performance, accuracy, and material selection for linings and electrodes.

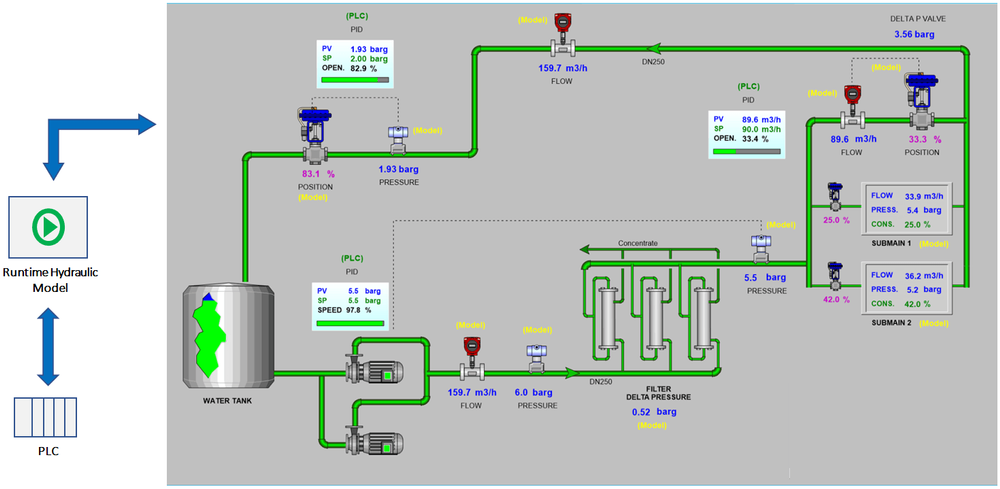

Waste Water PLC Wastewater Treatment Plant

The primary factors to consider are:

1 . Conductivity Requirements

Electromagnetic flowmeters require the medium to have a certain level of conductivity. Typically, electromagnetic flowmeters are designed to measure fluids with a conductivity range of 10⁻⁴ S/cm to 5×10⁻⁶ S/cm. If the medium’s conductivity is below this threshold, measurement errors or complete failure may occur. For low-conductivity fluids (e.g., certain oils), flowmeters with higher sensitivity or specialized designs may be necessary.

2 . Medium Composition and Gas Bubbles

Solid Particles: If the medium contains magnetic particles, such as iron filings, it may interfere with the flowmeter’s magnetic field, leading to measurement errors. In such cases, flowmeters with magnetic shielding capabilities are recommended.

Gas Bubbles: The presence of bubbles in the fluid can cause measurement errors, as bubbles will contribute to the total flow. To mitigate this, a bubble separation device or a flowmeter capable of compensating for bubbles can improve accuracy.

3 . Sediment and Scaling

Certain media, such as water with high calcium or magnesium content, may cause sediment or scale to accumulate on the pipe lining or electrodes, affecting measurement accuracy. Self-cleaning electrodes or flowmeters with anti-scaling features are recommended. For media prone to scaling, flowmeters with ceramic or PTFE linings can reduce wear and deposition.

4. Hygiene and Food-Grade Requirements

In industries such as food processing, pharmaceuticals, and chemicals, flowmeters must meet specific hygiene standards. The materials used in the flowmeter must comply with food-grade or GMP standards, such as stainless steel, PTFE, or PFA, ensuring that the flowmeter does not react with the medium and is easy to clean.

5. Corrosion Resistance

For corrosive media, such as acidic, alkaline liquids or chemical solutions, the corrosion resistance of the flowmeter lining and electrodes is critical. Materials like PTFE, PFA, or ceramic linings are recommended to ensure long-term durability, while electrodes made of corrosion-resistant materials like tantalum or platinum will help maintain measurement accuracy and stability.

Operating Condition Parameters

1. Temperature and Pressure

Temperature and pressure directly influence the performance and lifespan of electromagnetic flowmeters. For high-temperature fluids, flowmeters should be selected with linings that can withstand high temperatures, such as PTFE or PFA. For high-pressure environments, flowmeters made of pressure-resistant materials are required to ensure safety and prevent leakage.

2. Pipe Diameter and Flow Range Matching

The diameter of the electromagnetic flowmeter should match the pipe diameter to ensure proper operation within its effective flow range. A flowmeter with too large or too small a diameter may affect measurement accuracy. For low-flow or low-velocity applications, it is typically recommended to select a flowmeter with a slightly smaller diameter to improve sensitivity and accuracy.

3. Flow Velocity and Full-Scale Flow

The measurement accuracy of an electromagnetic flowmeter remains stable within a specific flow velocity range, typically 1 to 10 m/s for liquids. In practice, flow velocities above 5 m/s may cause wear on the flowmeter lining, especially if softer materials like rubber are used. For low-flow (below 1 m/s) applications, reducing the flowmeter’s diameter can help increase flow velocity and improve signal strength and accuracy.

Choosing the Right Accuracy Level

The accuracy level of the electromagnetic flowmeter is crucial for the precision of the measurements. Selecting the appropriate accuracy level based on the specific requirements helps avoid unnecessary costs.

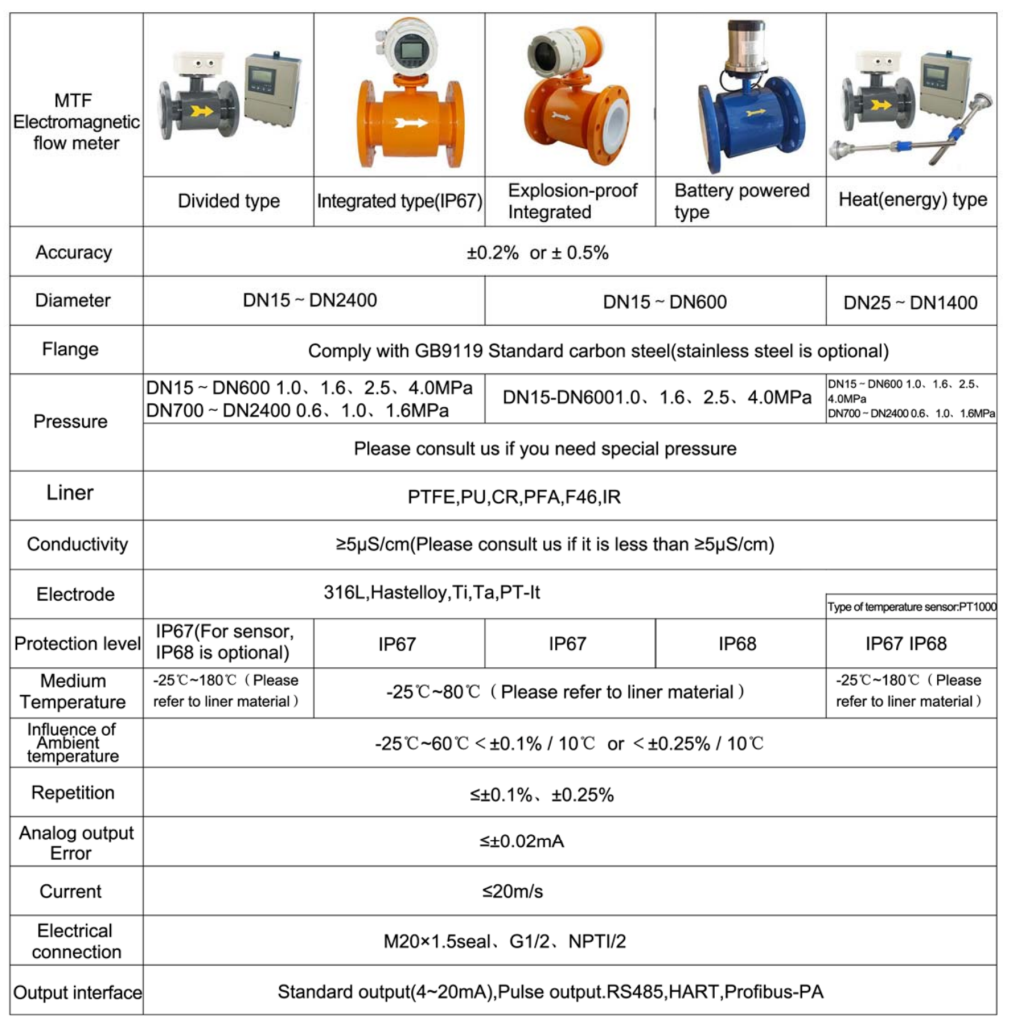

High-Accuracy Electromagnetic Flowmeters: Typically, these flowmeters have an error range of ±0.2% to ±0.5% and are suitable for applications that require highly precise measurements, such as metering and other precision-demanding environments.

Standard-Accuracy Electromagnetic Flowmeters: These flowmeters usually have an error range of ±1% to ±2% FS and are suitable for general industrial applications. They offer good value for money while meeting most operational requirements.

When selecting the accuracy level, consider the specific needs and budget. If high accuracy is not essential, opting for a standard-accuracy flowmeter can help minimize unnecessary costs.

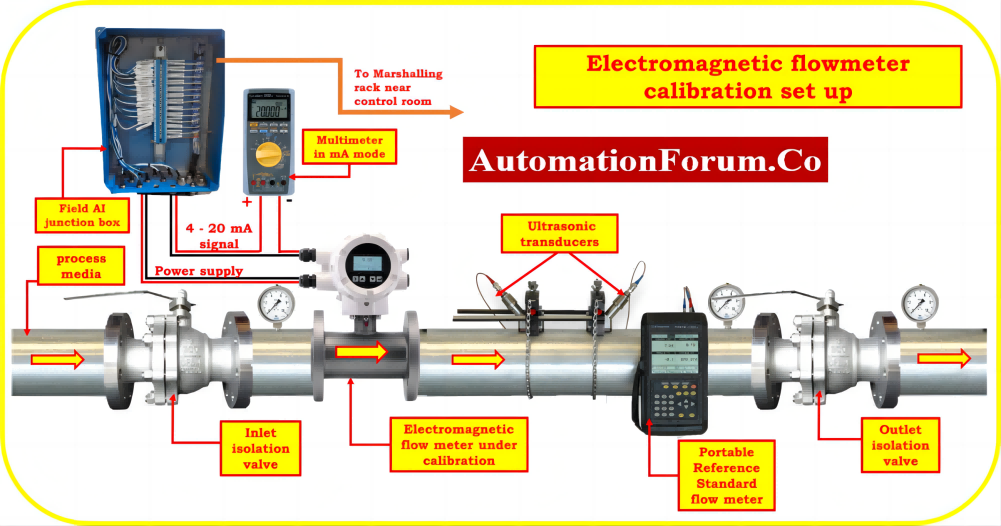

Source: automationforum.co

Magnetic Flow Meter Installation and Troubleshooting

- What precautions should be taken when using an electromagnetic flowmeter?

- What are the installation and environmental considerations for a magnetic flow meter?

- Troubleshooting Electromagnetic Flowmeters: Impact of Gas and Solid Contaminants

- Electromagnetic Flow Meter Troubleshooting Due to Changes in Flow Conditions

Conclusion

Selecting the right electromagnetic flowmeter requires careful consideration of several factors, including the characteristics of the measured medium, the operating temperature and pressure ranges, the flow velocity and flow range matching, and the required accuracy. By making an informed selection, you can ensure the electromagnetic flowmeter’s high performance, efficiency, and long-term reliability. This guide is designed to assist you in scientifically and accurately choosing the right electromagnetic flowmeter for your needs.

Leave a comment