Moisture control is a critical requirement in compressed air systems, industrial gases, natural gas pipelines, and many precision manufacturing processes. Excess water vapor can lead to corrosion, freezing, product defects, sensor failure, and even serious safety risks. This is why the dew point meter has become one of the most important instruments in modern gas quality monitoring.

This guide explains what a dew point meter is, where it is used, how it is installed, and most importantly, how to choose the right dew point meter for your application.

Table of Contents

What’s a Dew Point Meter?

A dew point meter (also called a dew point transmitter or moisture analyzer) is an instrument used to measure the dew point temperature of a gas. The dew point is the temperature at which water vapor in a gas begins to condense into liquid under constant pressure.

In simple terms:

- Lower dew point = drier gas

- Higher dew point = wetter gas

For example:

- −80 °C → ultra-dry gas for semiconductor or laser applications

- −40 °C → dry industrial compressed air

- 0 °C → humid air

- +10 °C → very wet gas

Unlike relative humidity (%RH), which depends on temperature, dew point directly represents the absolute moisture content of the gas, making it far more reliable for industrial process control.

What Does a Dew Point Meter Actually Measure?

A dew point meter does not directly measure water in liquid form. Instead, it measures moisture in the gas phase and converts it into a dew point temperature value using one of several sensor technologies (aluminum oxide, chilled mirror, ceramic capacitive, etc.).

Applications of a Dew Point Meter

Dew point meters are used anywhere that gas dryness directly affects safety, product quality, or equipment life. Below are the most common application sectors.

Compressed Air Systems (Most Common Application)

Compressed air always contains water vapor. Without proper drying and dew point monitoring, it can cause:

- Pipe corrosion

- Valve sticking

- Instrument air malfunction

- Product contamination

- Freezing in cold environments

Typical dew point range: −20 °C to −40 °C

Where installed: After air dryers, in main air headers, or before critical pneumatic equipment.

Industrial Gases (N₂, H₂, O₂, Ar, CO₂)

High-purity industrial gases are extremely sensitive to moisture. Even trace humidity can cause:

- Oxidation

- Surface defects

- Unstable chemical reactions

- Arc instability in welding

- Laser cutting quality issues

Typical dew point range: −40 °C to −80 °C

Applications: Nitrogen blanketing, hydrogen cooling, laser cutting, electronics manufacturing.

Natural Gas & Energy Systems

In natural gas pipelines and CNG/LNG systems, moisture can lead to:

- Hydrate formation

- Pipeline blockage

- Valve freezing

- Severe corrosion

Typical dew point range: −10 °C to −40 °C

Dew point monitoring ensures gas remains safely transportable under pressure.

Power & Electrical Insulation Systems (SF₆ / Dry Air)

High-voltage switchgear, GIS systems, and transformers rely on extremely dry insulation gas.

Excess moisture can lead to:

- Partial discharge

- Insulation breakdown

- Flashover accidents

Typical dew point range: −40 °C to −60 °C

Medical & Laboratory Gases

Medical oxygen and laboratory gases must remain dry to prevent:

- Instrument damage

- Measurement errors

- Safety hazards

Typical dew point range: −40 °C to −70 °C

Installation Types of Dew Point Meters

Choosing the right installation type is just as important as choosing the right sensor.

Inline Installation (Direct Installation)

The dew point sensor is mounted directly into the pipeline.

Advantages:

- Real-time continuous monitoring

- No sample conditioning system required

- Simple installation

Best for: Clean compressed air, stable gas pipelines.

Bypass / Sampling Installation

A small portion of gas is extracted from the main pipeline and routed to a sampling chamber.

Advantages:

- Better control of pressure and flow

- Easier maintenance

- Allows use of filters, regulators, and dryers

Limitations:

- Slower response time

- Requires additional piping and components

Best for: High-pressure gas, dirty gas, natural gas, hydrogen systems.

Portable Dew Point Meters

Handheld instruments used for spot checks.

Advantages:

- Flexible

- No installation needed

- Ideal for maintenance verification

How to Choose a Dew Point Meter

This is the most critical part of dew point meter selection. A correct choice depends on process conditions, gas type, required accuracy, and operating environment.

1. Determine the Required Dew Point Range (Most Important Step)

Typical measurement ranges:

| Application | Typical Range |

|---|---|

| General compressed air | −20 °C to +20 °C |

| Dry industrial air | −40 °C to −10 °C |

| Industrial gases | −60 °C to −30 °C |

| Ultra-dry gases | −80 °C to −100 °C |

✅ Best practice: Your normal working dew point should fall in the middle 30–70% of the sensor range, not near the extreme ends.

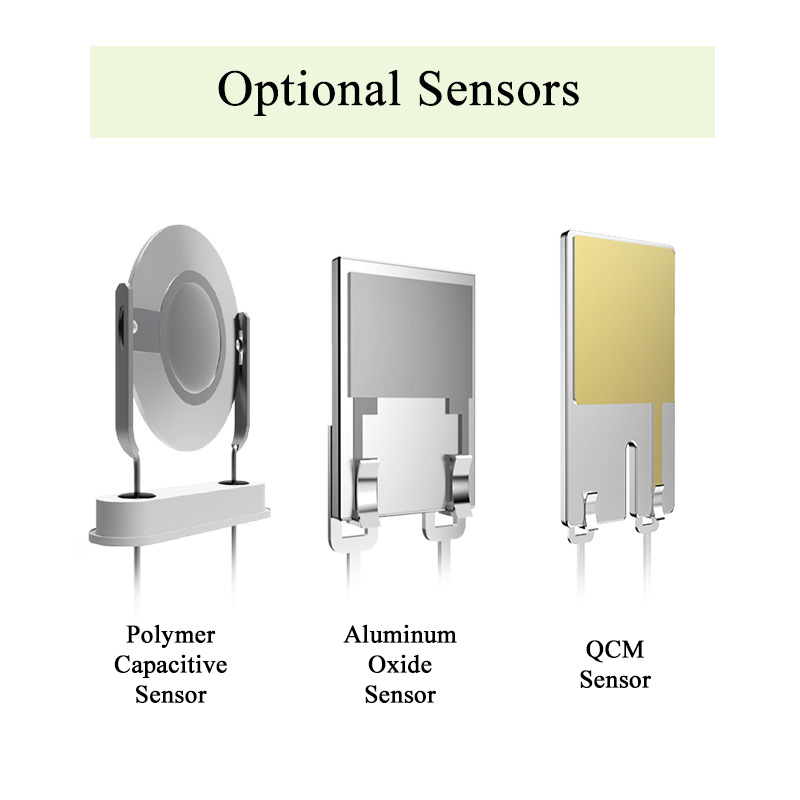

2. Select the Right Sensor Technology

Aluminum Oxide Sensor (Most Common Industrial Choice)

- Wide range down to −100 °C

- Stable, durable

- Ideal for compressed air, nitrogen, hydrogen, natural gas

- Sensitive to oil and solvent contamination

Chilled Mirror Sensor (Reference Standard)

- Highest accuracy

- True physical dew point

- Expensive and complex

- Used mainly for calibration and laboratories

Capacitive Ceramic Sensor

- Low cost

- Compact

- Limited ultra-low dew point capability

- Suitable for HVAC and general air monitoring

3. Accuracy and Resolution Requirements

- High-end industrial: ±0.1–0.3 °C

- Standard industrial: ±1–2 °C

Do not over-specify accuracy unless necessary—higher accuracy always means higher cost.

4. Response Time

- Fast (<10 s): gas switching, batch control

- Normal (20–60 s): continuous monitoring

- Slow (>60 s): non-critical monitoring

Faster response usually increases cost.

5. Pressure and Temperature Ratings

Always verify:

- Working pressure: 0–1 MPa (standard), up to 4–10 MPa for natural gas / CNG

- Gas temperature: typically −20 °C to +60 °C at the sensor

Incorrect pressure rating can permanently damage the sensor.

6. Gas Compatibility

Confirm compatibility with:

- Air

- N₂, H₂, O₂

- Natural gas / methane

- CO₂

- SF₆

Some sensors are not suitable for corrosive gases or high hydrogen concentrations.

7. Contamination and Sample Conditioning

If your gas contains:

- Oil mist

- Dust

- Solvents

You must install:

- Particle filter

- Coalescing oil filter

- Pressure regulator

- Flow restrictor

Without proper conditioning, sensor lifetime will be drastically reduced.

8. Output Signals and Communication

Common outputs:

- 4–20 mA

- 0–10 V

- RS485 / Modbus

- HART

- Relay alarms

Choose based on your PLC, DCS, or SCADA system.

9. Certifications and Hazardous Area Requirements

Some applications require:

- ATEX / IECEx

- Explosion-proof housings

- SIL safety certification

Especially important for hydrogen, natural gas, and chemical plants.

Final Summary

A dew point meter is not just a moisture sensor—it is a critical protection device for gas systems. Choosing the right model requires a clear understanding of:

- The application

- The required dew point range

- The installation method

- The sensor technology

- The pressure, contamination, and safety conditions

Golden Selection Rule

Always define the dew point range first, then select the sensor technology, then verify pressure, contamination protection, and signal output.

With correct selection and installation, a dew point meter ensures long-term reliability, reduced maintenance cost, and maximum process safety.