Natural gas is a cornerstone of global energy systems, powering industries, heating homes, and fueling transportation. As the demand for cleaner energy grows, accurate measurement of natural gas flow becomes critical for efficiency, safety, and regulatory compliance. Natural gas flow meter is a device designed to measure the volume or mass of natural gas moving through pipelines, ensuring precise billing, leak detection, and system optimization.

Table of Contents

What is a Natural Gas Flow Meter?

A natural gas flow meter is an instrument that measures the volumetric or mass flow rate of natural gas (primarily methane, CH₄) in pipelines or distribution systems. These meters account for variables like pressure, temperature, and gas composition to provide accurate readings, which are essential for:

- Custody transfer (billing between suppliers and consumers).

- Leak detection and emissions monitoring.

- Process control in industrial applications.

Natural gas flow meters are used across sectors, including oil and gas, utilities, manufacturing, and residential energy distribution.

Why is a Natural Gas Flow Meter Important?

1. Financial Accuracy

- Natural gas is often traded in large volumes, and even minor measurement errors can lead to significant revenue loss or overcharging.

2. Safety and Leak Prevention

- Natural gas is flammable and poses explosion risks. Flow meters detect leaks or irregular flow patterns early, preventing accidents.

3. Regulatory Compliance

- Governments enforce strict standards (e.g., API, ISO, AGA) for natural gas measurement and emissions. Accurate meters ensure compliance and avoid penalties.

4. Operational Efficiency

- Optimizes gas usage in industrial processes, reducing waste and energy costs.

5. Environmental Protection

- Monitors methane emissions, a potent greenhouse gas, supporting sustainability goals.

Recommended Flow Meter Types for Natural Gas

Choosing the right meter depends on factors like flow rate, pressure, accuracy needs, and budget. Below are the top options:

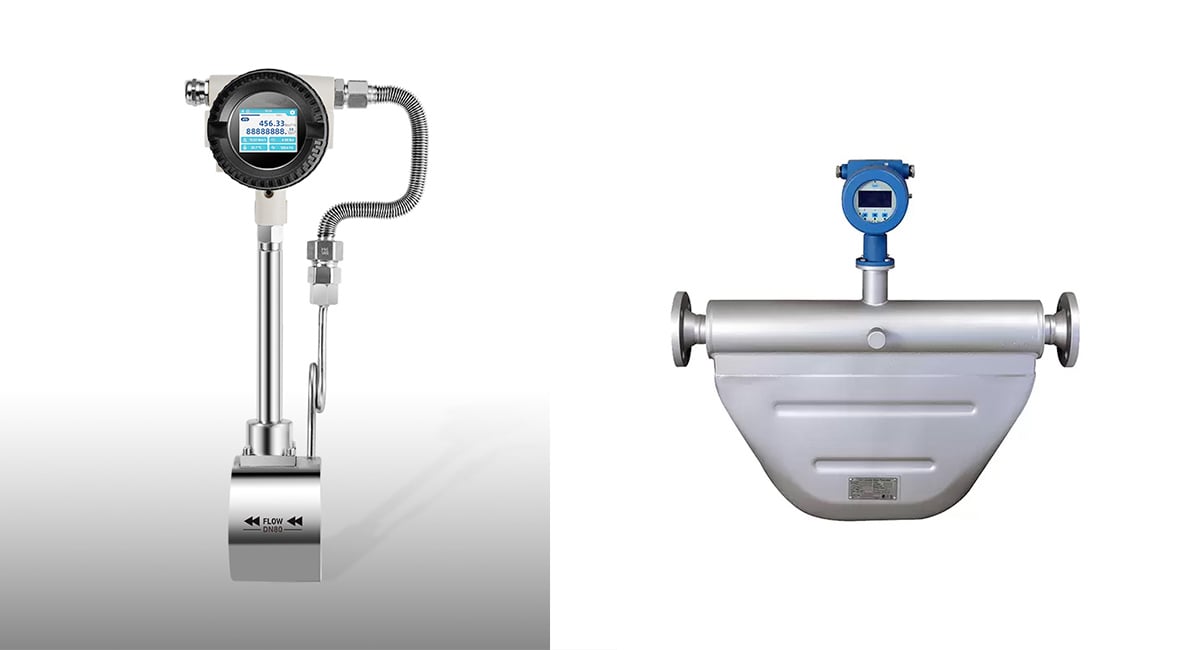

1. Thermal Mass Flow Meters

How They Work:

Measure heat dissipation from a heated sensor to calculate mass flow.

Advantages:

- Direct mass flow measurement (no compensation needed).

- High accuracy (±1–2%).

- Ideal for low-flow applications.

Features:

- Explosion-proof class: Ex db IIC T6 Gb / Ex tb IIIC T80°CDb.

- Medium: Compressed air, nitrogen, oxygen, Carbon dioxide & other non-condensing gases.

- Ultra-wide 1:2500 turndown ratio, the measuring range is from 0.1 Nm/s to 250 Nm/s.

- Full-digital signal processing, higher accuracy, long-term stability.

2. Coriolis Mass Flow Meters

How They Work:

Measure mass flow via the Coriolis effect in vibrating tubes.

Advantages:

- Extreme accuracy (±0.1%).

- Immune to pressure/temperature changes.

- Measures density and temperature simultaneously.

Features:

- High accuracy up to ±0.1 %, Good reliability

- Good zero-stability and anti-interference performance

- No moving parts, no maintenance required

- Multiple digital communication including Hart

3. Turbine Gas Flow Meters

How They Work:

A rotor spins as gas flows through the meter, with rotational speed proportional to flow rate.

Advantages:

- Suitable for high-pressure systems.

- Cost-effective for large-diameter pipelines.

Features:

- Temp. & pressure compensation.

- Segment LCD, displays normally at -30℃

- Integrated movement

- Communication: Modbus RS485

- Simultaneous display flow rate, total flow volume, pressure & temp.

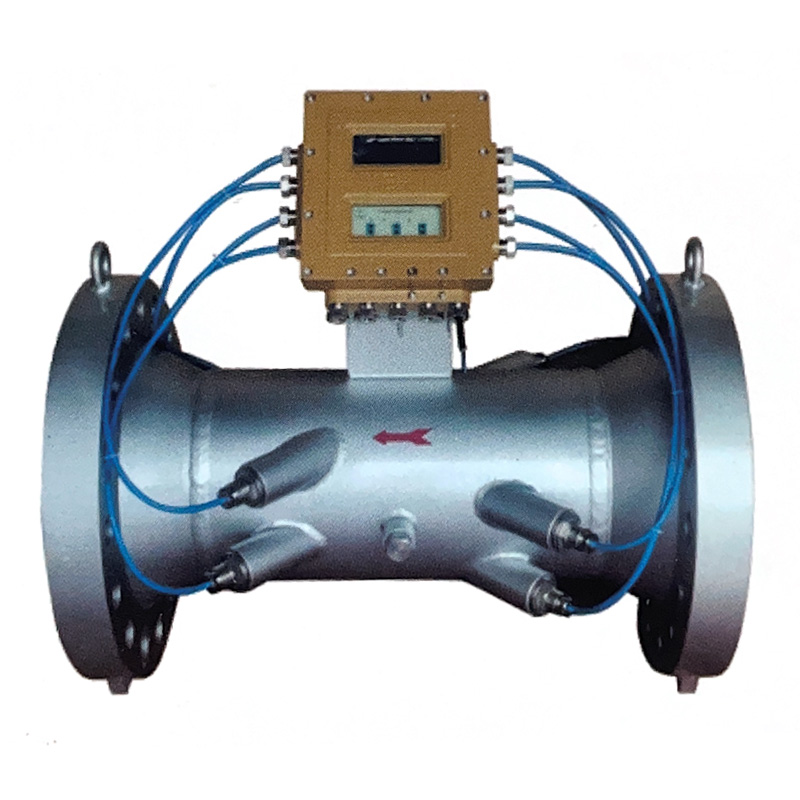

4. Ultrasonic Flow Meters

How They Work:

Use ultrasonic waves to measure flow velocity via transit-time or Doppler methods.

Advantages:

- Non-invasive clamp-on models available.

- No pressure drop or pipe modifications.

- Bidirectional flow measurement.

Features:

- High accuracy for gas up to ±0.5%

- No moving parts, no presure loss, no line obstructions

- No lubrication or periodic maintenance

- Measurement is not affected by gas properties

- Wide turndown ratio

- Bi-directional capability

How to Choose a Natural Gas Flow Meter

1. Define Application Requirements

- Flow Range: From residential meters (0.1–10 m³/h) to industrial pipelines (10,000+ m³/h).

- Pressure and Temperature: High-pressure systems may need turbine or Coriolis meters.

- Accuracy Needs: ±0.1% for custody transfer vs. ±2% for process monitoring.

2. Assess Gas Composition

- Natural gas often contains impurities (e.g., CO₂, H₂S). Choose meters resistant to corrosion (e.g., stainless steel Coriolis).

3. Installation Environment

- Hazardous Areas: ATEX/IECEx-certified meters for explosive atmospheres.

- Pipe Size: Ultrasonic clamp-on meters for large pipes (>12 inches).

4. Budget and Total Cost of Ownership (TCO)

- Factor in maintenance, calibration, and energy savings. Example: Coriolis meters have high upfront costs but low lifetime TCO.

Applications of Natural Gas Flow Meters

- Oil and Gas Production:

- Meter Type: Turbine or Coriolis.

- Purpose: Custody transfer between producers and distributors.

- Residential Utilities:

- Meter Type: Diaphragm or rotary meters.

- Purpose: Billing households for gas consumption.

- Power Generation:

- Meter Type: Ultrasonic.

- Purpose: Monitor gas feed to turbines for efficient energy production.

- Industrial Heating:

- Meter Type: Thermal mass.

- Purpose: Control gas flow to furnaces and boilers.

Common Mistakes to Avoid

- Ignoring Gas Purity: Impurities can damage sensitive meters like thermal mass.

- Overlooking Calibration: Even high-end meters drift over time.

- Choosing Based on Price Alone: Cheap meters may lack accuracy or durability.

Natural gas flow meters are vital for ensuring safe, efficient, and profitable operations across the energy value chain. Whether you’re managing a sprawling pipeline or optimizing a manufacturing plant’s gas usage, selecting the right meter—turbine, ultrasonic, Coriolis, or another type—requires careful evaluation of flow conditions, accuracy needs, and total costs.