Our client is a leading operator in the Metal & Mining industry, heavily reliant on diesel to power various machinery and equipment used in the extraction and production processes. Accurate flow measurement of diesel is critical to ensure the efficient operation of equipment and minimize fuel waste, which can have significant operational cost implications.

Application:

Monitoring the Diesel Flow in a Mining Company’s Equipment

Requirements:

- High-accuracy, explosion-proof flow meter.

- Filter to remove impurities for use with birotor flow meter.

Challenge

The client faced significant challenges in accurately measuring the flow of diesel fuel used in their high-flow systems. Diesel is a critical resource for powering machinery, and any inaccuracies in measurement could result in fuel inefficiency and equipment downtime. Additionally, the operational environment posed risks of explosion due to hazardous gases, necessitating explosion-proof equipment. Furthermore, the diesel fuel contained impurities such as particulate matter and gas bubbles, which could disrupt flow measurement and impact equipment performance.

Application

- Diesel Flow Monitoring: Accurate monitoring of diesel flow in mining machinery and equipment.

- Fuel Filtration: Ensuring the diesel fuel remains free from contaminants and gas bubbles, which could impair the accuracy of the flow measurement system.

Solution Provided by Metlan

Metlan provided a tailored solution to meet the client’s specific needs for high accuracy, explosion-proof performance, and effective filtration of diesel fuel. The solution combined two key components: the Metlan ABR Bi-Rotor Flow Meter and the MT-LPGX Air Eliminator/Strainer.

1. Metlan Birotor Flow Meter (MT-ABR)

The MT-ABR Bi-rotor is a positive displacement flow meter utilized in the most demanding applications requiring accuracy, long life and ruggedness, which is a perfect choice for fuel and diesel oil. It is available in two configurations, integral mechanical registration or electronic output. The bi-rotor flow meter has high accuracy up to ±0.1 % and high process pressure up to 110 bar (1595 psi).

Design & Accuracy: Available in three accuracy classes—0.1%, 0.2%, and 0.5%—it delivers exceptional precision across various operational conditions.

Key Features:

- High Accuracy: With an accuracy of up to 0.1%, the ABR Bi-Rotor Flow Meter ensures precise flow measurement, which is critical for efficient fuel management.

- Low Pressure Loss: The meter’s design minimizes pressure loss, improving system efficiency and ensuring smooth and consistent operation.

- Long-Lasting Durability: Featuring a self-lubricating design, it reduces wear and tear, extending the service life and reducing maintenance costs.

- Minimal Noise & Vibration: Its low-noise and low-vibration operation make it ideal for environments where minimizing operational disruptions is essential.

- Explosion-Proof: The flow meter is certified to operate in hazardous environments, meeting explosion-proof standards that protect both personnel and equipment.

- Advanced Features: The meter supports remote communication, mass flow conversion, and temperature/pressure acquisition, providing enhanced functionality and operational flexibility.

Advantages:

- High Accuracy: We also offer accuracy options of 0.1%, 0.2%, and 0.5%.

- Trusted Supplier: We are an approved supplier for PetroChina and Sinopec, ensuring high product quality.

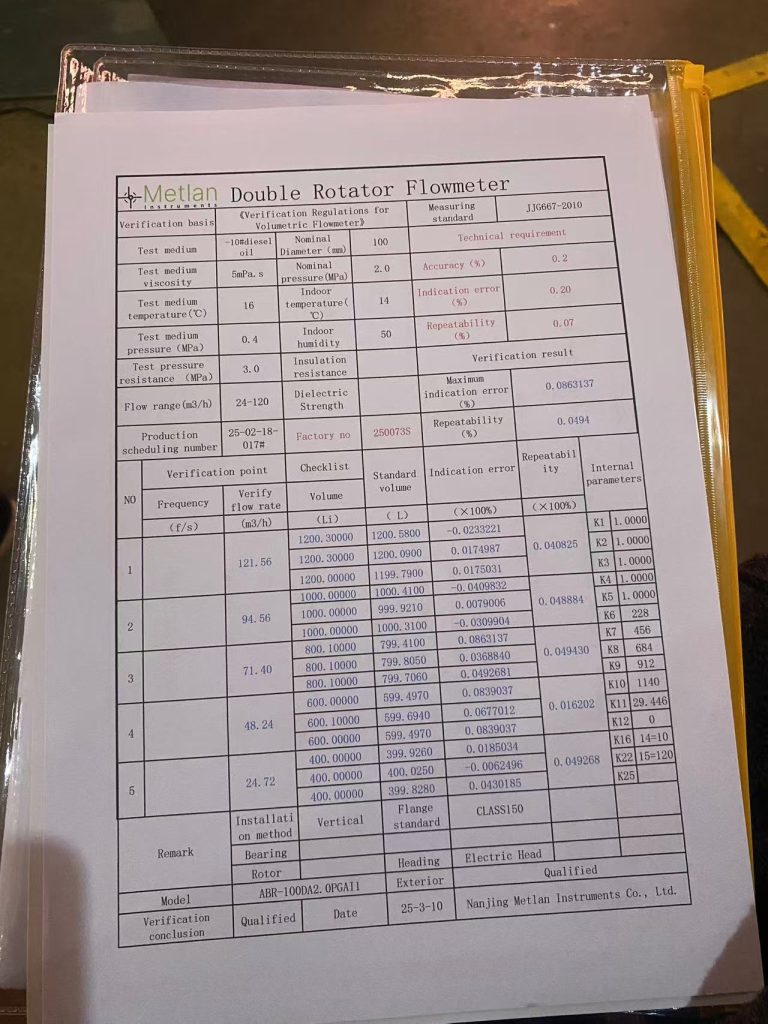

- Quality Assurance: Every flow meter undergoes factory testing, calibration, and comes with a calibration report.

2. Air Eliminators / Strainers (MT-LPGX)

Filtration & Gas Elimination: The Metlan LPGX Filter and Gas Eliminator ensures that the diesel fuel is free of particulates and gas bubbles, which could cause inaccuracies in the flow measurement. It works in tandem with the bi-rotor flow meter to provide clean, reliable fuel flow readings.

Nominal Diameter Range | DN 15 to 800 (½” to 32″) |

|---|---|

Medium Temperature Range | Standard: (-20~+100) ℃ , Optional: (-20~+250) ℃ |

Max. Process Pressure | 64 bar (928.24 psi) |

Mesh Number | 10 to 40 (Others on request) |

Key Benefits:

- Efficient Filtration: The filter ensures that contaminants, such as dirt, rust, or other debris, do not enter the flow meter, ensuring that the system remains clean and operational.

- Gas Bubble Removal: The gas eliminator removes air bubbles or vapor from the fuel, preventing their impact on the accuracy of the flow meter and ensuring consistent fuel measurement.

- Durability: Like the bi-rotor flow meter, the LPGX filter is designed to handle harsh industrial conditions and operate efficiently over long periods with minimal maintenance.

Conclusion

Metlan’s comprehensive diesel flow measurement solution, combining the ABR Bi-Rotor Flow Meter and MT-LPGX Air Eliminator/Strainer, provided the client with a highly accurate, durable, and safe system for monitoring diesel flow. This solution not only addressed the client’s immediate challenges related to fuel efficiency, safety, and contamination but also delivered long-term operational benefits by reducing maintenance needs and improving equipment reliability. Metlan’s tailored approach effectively supported the client’s goals of minimizing fuel waste and ensuring the smooth operation of their mining equipment.