Measuring gas flow accurately is critical in industries ranging from natural gas distribution to chemical processing, semiconductor manufacturing, and laboratory research. Choosing the right gas meter depends not only on the required accuracy and budget but also on the type of gas, flow rate range, and environmental conditions.

This article provides a complete overview of types of gas meters, including their working principles, suitable applications, advantages, and limitations and offers guidance on selecting the best option for your needs.

Table of Contents

Understanding Gas Types

Before selecting a gas meter, it’s essential to understand the nature of the gas you’ll be measuring. Gas properties significantly influence measurement accuracy, meter longevity, and maintenance requirements.

1. Dry Gas

- Definition: Gas without significant moisture content, e.g., compressed air, nitrogen, argon, hydrogen.

- Challenges: Minimal, but contamination, oil mist, or dust can still cause wear in mechanical meters.

- Meter Implication: Most gas meters work well; thermal and Coriolis meters often excel due to their clean measurement path.

2. Wet Gas

- Definition: Gas containing water vapor or entrained liquid droplets, e.g., saturated steam, biogas with high humidity.

- Challenges: Moisture can condense and cause corrosion, measurement errors, or thermal probe damage.

- Meter Implication: Avoid thermal mass meters unless moisture is removed; vortex, Coriolis, and certain DP-based meters are better choices, like Pitot Tube flow meters.

3. Gas with Particulates

- Definition: Gases with suspended solids such as dust, ash, or fine powders—common in flue gases or process exhaust.

- Challenges: Erosion of sensor surfaces, clogging of narrow passages, signal scattering in ultrasonic meters.

- Meter Implication: Use robust, wear-resistant materials; consider non-intrusive ultrasonic meters or protected DP probes.

4. Single Gas

- Definition: A gas of consistent composition (e.g., pure oxygen, pure hydrogen, pure chlorine).

- Challenges: Relatively simple measurement but may require specialized calibration for accuracy.

- Meter Implication: Thermal mass meters and Coriolis meters provide excellent accuracy when calibrated for the specific gas.

5. Gas Mixtures

- Definition: Gases composed of multiple components (e.g., natural gas, syngas, specialty blends).

- Challenges: Composition variation can impact density-based or thermal-based measurements.

- Meter Implication: Coriolis meters are ideal as they measure true mass flow independent of composition; multi-gas-capable thermal meters can also work.

Types of Gas Flow Meter

Below are the most common gas meter types, their principles, suitable gas types, flow ranges, and pros and cons.

Thermal Mass Flow Meters

Principle: Measure gas mass flow by detecting the heat loss from a heated sensor in the gas stream. The cooling rate correlates with mass flow.

Suitable Gas Types:

- Best for dry, clean gases

- Works well for single gases

- Can measure some gas mixtures with multi-gas algorithms

Flow Range:

- Very low to medium flow rates

- Ideal for applications from a few SCCM (standard cubic centimeters per minute) up to thousands of SLPM

Advantages:

- Direct mass flow measurement—no need for temperature and pressure compensation

- No moving parts—low maintenance

- Excellent for low flow rates

Disadvantages:

- Not suitable for wet gases or high particulate content

Coriolis Mass Flow Meters

Principle: Measure mass flow by detecting the phase shift caused by the Coriolis effect in vibrating tubes through which the gas flows.

Suitable Gas Types:

- Works with almost all gases (dry, wet, particulate-laden)

- Handles single gases and gas mixtures with high accuracy

Flow Range:

- Can be used in custody transfer applications

- Low to medium flow rates (small-bore designs for low flows)

Advantages:

- True mass flow measurement regardless of temperature, pressure, or composition changes

- Measures density as well

- Extremely accurate and stable

Disadvantages:

- High cost compared to other technologies

- Pressure drop can be significant in some designs

Vortex Flow Meters

Principle: Measure volumetric flow by detecting vortices shed by a bluff body in the gas stream. The frequency of vortices is proportional to flow velocity.

Suitable Gas Types:

- Dry and wet gases, including steam

- Works for some dirty gases if particulate load is not excessive

Flow Range:

- Medium to high flow rates

- Often used in steam distribution lines

Advantages:

- Robust and reliable with no moving parts

- Can handle high temperatures and pressures

- Suitable for saturated or superheated steam

Disadvantages:

- Not suitable for very low flow rates

- Accuracy affected by pulsating flows or vibration

Gas Turbine Meters

Principle: Use a turbine rotor whose rotational speed is proportional to the volumetric flow rate of gas.

Suitable Gas Types:

- Clean, dry gases (natural gas, compressed air)

Flow Range:

- Medium to high flow rates

Advantages:

- High accuracy for medium to high flow rates

Disadvantages:

- Moving parts wear over time, requiring maintenance

- Sensitive to contamination and debris

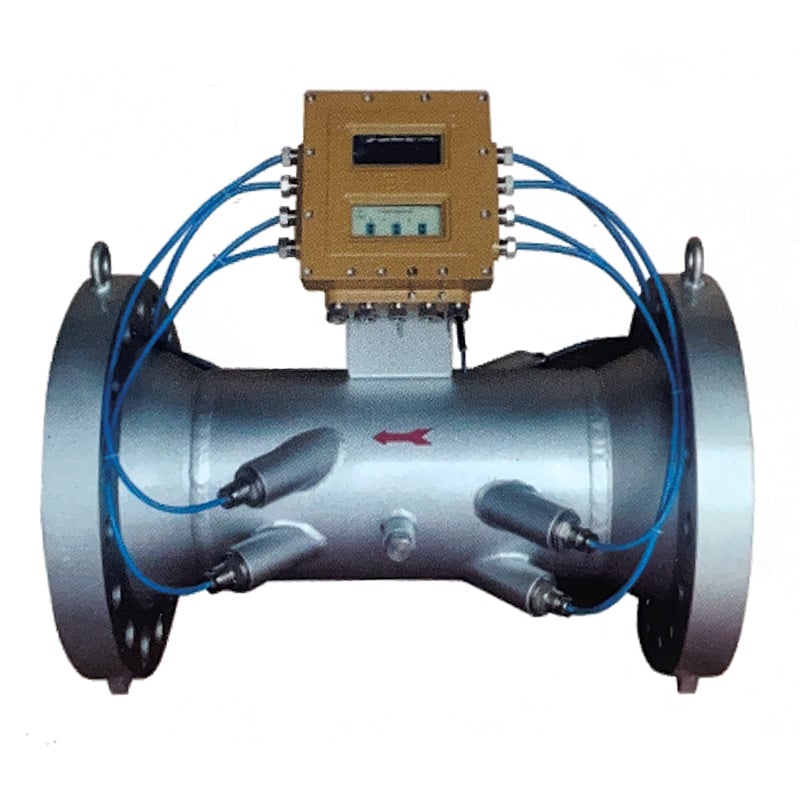

Ultrasonic Flow Meters

Principle: Measure flow velocity using ultrasonic sound waves, either transit-time or Doppler effect methods.

Suitable Gas Types:

- Clean, dry gases for transit-time

- Some Doppler designs can handle particulate-laden gases

Flow Range:

- Medium to very high flow rates

- Excellent for large pipelines

Advantages:

- No pressure drop

- Suitable for large-diameter pipes

Disadvantages:

- Transit-time requires clean gas for accuracy

- More expensive than some alternatives

Pitot Tube Flow Meters

Principle: Measure differential pressure between static and dynamic pressure ports to determine gas velocity.

Suitable Gas Types:

- Works with almost all gases (dry, wet, dirty air)

- Often used in duct or stack monitoring

Flow Range:

- Low to high velocities

Advantages:

- Simple and easy to install

- Bidirectional flow measurement

Mass Flow Controllers (MFCs)

Principle: Combine a mass flow meter (usually thermal or Coriolis) with a control valve to regulate gas flow to a setpoint.

Suitable Gas Types:

- Dry, clean gases (thermal MFC)

- Coriolis MFC can handle gas mixtures and varying compositions

Flow Range:

- Very low to low flow rates (from SCCM to tens of SLPM)

Advantages:

- Precise flow measurement and control in one device

- Excellent for laboratory and semiconductor processes

- High repeatability

Disadvantages:

- Limited to low flows

- Thermal types sensitive to gas composition

Summary Table

| Meter Type | Best For | Flow Range | Pros | Cons |

|---|---|---|---|---|

| Thermal Mass | Dry, clean gas, low flow | low–medium | High accuracy, no moving parts | Sensitive to moisture & composition change |

| Coriolis | Any gas, including mixtures | Low–medium | True mass flow, very accurate | High cost, pressure drop |

| Vortex | Dry/wet gas, steam | Medium–high | Robust, high temp capability | Not for very low flow |

| Gas Turbine | Clean, dry gas | Medium–high | Accurate for high flow rates | Wear, sensitive to debris |

| Ultrasonic | Large pipes, clean gas (or doppler dirty) | Medium–very high | Non-intrusive, no pressure drop | High cost, requires clean gas (transit) |

| Pitot Tube | wet and dirty gas | Low–high | Simple, Bidirectional flow measurement | |

| MFC | Low flow, precision control | Very low–low | Control + measurement in one | Limited flow range, cost |

How to Choose the Right Gas Meter

When selecting a gas meter, consider the following factors:

- Gas Type

- Dry gases → Thermal, Coriolis, Vortex, Ultrasonic, Turbine

- Wet gases → Vortex, Coriolis, Pitot Tube

- Gases with particulates → Ultrasonic (non-intrusive), Pitot Tube, robust mechanical designs

- Single gas → Thermal, Pitot Tube or Coriolis with single-gas calibration

- Gas mixtures → Coriolis, multi-gas thermal, Pitot Tube

- Flow Range

- Very low flow → Thermal mass meters or MFCs

- Medium to high → Vortex, Turbine, Ultrasonic, Coriolis, Pitot Tube

- Accuracy Requirements

- Custody transfer → Coriolis

- Process control → Thermal, Vortex, Pitot Tube depending on gas

- Installation Environment

- High temperature or steam → Vortex

- Hazardous areas → Ensure meter has proper certifications

- Budget

- Low → Vortex, some thermal designs

- Medium → Pitot Tube

- High → Coriolis, high-end ultrasonic

Choosing the right gas meter is about matching the meter technology to your gas type, flow rate, and accuracy needs. No single meter fits all applications. By carefully analyzing your process conditions, you can select a gas meter that ensures accurate, reliable, and cost-effective performance for years to come.