Gasoline is the lifeblood of the transportation and fuel industry. It powers vehicles, machinery, and generators across the globe. Because gasoline is highly flammable, volatile, and economically valuable, measuring its flow accurately and safely is a critical concern in industries such as petrochemicals, fuel distribution, and retail fueling stations.

This is where gasoline flow meters come into play. In this comprehensive guide, we’ll walk you through everything you need to know about gasoline as a fluid, its characteristics, what gasoline flow meters are, the recommended types for gasoline applications, and most importantly—how to choose the right one for your specific use case.

Table of Contents

Top 5 Recommended Oil Flow Meters

What is Gasoline?

Gasoline, also known as petrol in many parts of the world, is a transparent, petroleum-derived liquid used primarily as a fuel in internal combustion engines. It is produced during the fractional distillation of crude oil and is further enhanced with additives to improve performance, reduce emissions, and prevent engine knock.

Key Characteristics of Gasoline:

- Highly Flammable: Gasoline vapors can ignite easily and pose a significant explosion risk.

- Volatile: Gasoline evaporates quickly, making containment and measurement tricky.

- Low Viscosity: Typically around 0.5–0.8 centipoise at 20°C.

- Density: Around 0.71–0.77 kg/L depending on blend and additives.

- Temperature Sensitivity: Gasoline volume can expand or contract significantly with temperature changes.

- Hydrocarbon Composition: A mix of alkanes, cycloalkanes, and aromatic hydrocarbons.

These properties directly affect how gasoline should be stored, handled, and measured.

What is a Gasoline Flow Meter?

A gasoline flow meter is a device designed to measure the volume or mass of gasoline flowing through a pipeline or dispensing system. These meters are essential for:

- Fuel dispensing at gas stations

- Fuel delivery trucks and tankers

- Industrial process control

- Fuel inventory management

- Custody transfer and billing

Since gasoline is volatile and dangerous, the flow meter must be not only accurate and repeatable, but also explosion-proof, corrosion-resistant, and compatible with hydrocarbons.

Recommended Gasoline Flow Meter Types

Not all flow meters are suitable for gasoline due to its flammability and chemical composition. Here are the most widely used technologies:

1. Positive Displacement (PD) Flow Meters

Best for: Fuel delivery trucks, custody transfer, high-accuracy dispensing

How it works: PD meters trap fixed volumes of gasoline and count the number of times the chamber fills and empties.

Advantages:

- Very high accuracy (±0.1–0.5%)

- Good for low and medium flow rates

- Does not require straight pipe runs

Limitations:

- Moving parts can wear over time

Recommended PD Flow Meters for Gasoline:

Birotor High Accuracy PD Flowmeter with Mechanical Counter:

- High accuracy up to ±0.1 %.

- Explosion-proof class: Ex db IIC T6 Gb

- Stable in running with low voice.

- Good anti-interference performance and long service life.

- Strong applicability to viscosity changes.

- High-precision measurement with up to ±0.2% accuracy.

- Explosion-proof class: Ex db IIC T6 Gb.

- Not sensitive to the viscosity change.

- Simple installation without requiring straight pipe runs.

- Supporting HART and RS485 communication protocols

Positive Displacement Gear Flow Meter:

- Designed for low flow liquids from 0.6 L/H.

- High-precision measurement with up to ±0.5% accuracy.

- Explosion-proof class: Ex db IIC T6 Gb.

- 150:1 wide turndown ratio.

- Capable of measuring highly corrosive medium including sulfuric acid, hydrofluoric acid, and other aggressive chemicals.

2. Coriolis Mass Flow Meters

Best for: Precision fuel blending, laboratory fuel tests, high-end applications

How it works: Measures mass flow directly via Coriolis effect; also provides density and temperature.

Advantages:

- Extremely accurate (±0.1–0.2%)

- Measures mass, not just volume

- No moving parts

Limitations:

- High cost

- Heavier and bulkier than other types

- High accuracy up to ±0.1 %, Good reliability.

- Explosion-proof class: Ex db IIC T6 Gb.

- Good zero-stability and anti-interference performance.

- No moving parts, no maintenance required.

- Supporting HART and RS485 communication protocols.

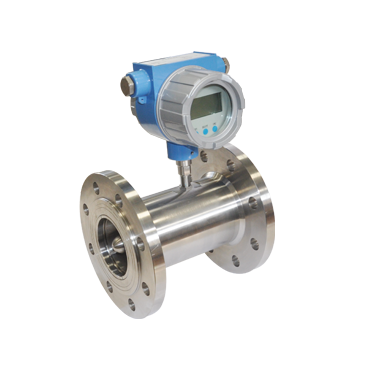

3. Turbine Flow Meters

Best for: Inline fuel measurement in clean systems, bulk flow

How it works: Flow turns a turbine rotor; the rotational speed is proportional to flow rate.

Advantages:

- Good accuracy (±0.5–1.0%)

- Low pressure drop

- Fast response time

Limitations:

- Sensitive to fluid viscosity and contamination

- Requires straight pipe lengths

- High accuracy up to ±0.2 %, with good repeatability.

- Explosion-proof class: Ex db IIC T6 Gb.

- 1:20 turndown ratio.

- Space-saving structure with DN0.5 minimum bore size.

Recommended Gasoline Flow Meters and Applications

Let’s take a closer look at where gasoline flow meters are used and which types are best for each case:

| Application | Recommended Meter Type | Key Requirements |

|---|---|---|

| Gas stations | PD meters or turbine meters | ATEX-certified, high accuracy, compact |

| Fuel trucks | Oval gear PD meters | Vibration resistant, portable, rugged |

| Refineries | Coriolis meters | High precision, integrated density reading |

| Bulk terminals | Turbine or PD meters | Large pipe sizes, custody transfer accuracy |

| Generators and machinery | PD meters | Small footprint, explosion-proof |

| Aviation fueling | Coriolis or PD meters | Lightweight, traceable accuracy |

How to Choose the Right Gasoline Flow Meter

Choosing a gasoline flow meter is not just about selecting the most accurate or expensive one. The key is to match your specific application, safety needs, and budget. Here are the key steps:

1. Define the Purpose

- Do you need totalized volume for billing or inventory?

- Do you need real-time flow rate for process control?

- Will you install the meter permanently or use it portably?

2. Determine Flow Range and Pipe Size

Select a meter with a flow range that matches your expected minimum and maximum flows. Oversizing or undersizing can severely affect accuracy.

3. Assess Fluid Properties

Gasoline blends can differ by region and season. Know the temperature, viscosity, and pressure at which the fluid will be measured.

4. Choose Appropriate Materials

Look for meters with aluminum, stainless steel, or PTFE linings—materials that resist gasoline corrosion and chemical attack.

5. Consider Output and Integration

Do you need a digital display? RS485/Modbus communication? Pulse output? Choose a meter that can interface with your control system, PLC, or mobile reader.

6. Maintenance and Calibration

Choose a design that allows for easy cleaning, inspection, and recalibration. Some meters include self-diagnostic or smart alerts for calibration drift.

Optional Accessories

- Strainers or filters: Prevent debris from damaging the flow meter.

- Explosion-proof enclosures: For hazardous zones.

- Flow totalizers: For remote or centralized flow monitoring.

- Temperature and pressure compensators: For improved accuracy in fluctuating environments.

- Installed upstream with the flow meter to ensure the fluid entering the device is free of air or gas.

- Removes entrained air or gas from the fluid.

- protecting all downstream system components.

- Prevents inaccuracies caused by air pockets or bubbles in the fluid, which can disrupt flow measurements.

Best Practices for Installing Gasoline Flow Meters

To ensure longevity and accuracy:

- Avoid placing meters near pumps or valves that cause turbulence.

- Use proper grounding to avoid static discharge.

- Follow the manufacturer’s recommendation for straight pipe lengths.

- Always pressure-test the system after installation.

- Regularly inspect and recalibrate the meter as required.

Accurate measurement of gasoline is critical not only for financial accountability and inventory control, but also for safety and compliance. Whether you’re operating a fuel station, managing an oil terminal, or simply monitoring generator fuel use, the right gasoline flow meter can make a significant difference in performance and reliability.

While Positive Displacement and Turbine flow meters remain the most popular for general gasoline applications, Coriolis mass flow meters are ideal for high-accuracy or scientific uses.

When in doubt, consult with flow meter experts who can recommend solutions tailored to your operating conditions.