In chlorine production and chemical processing, precise chlorine gas flow measurement and control is essential for process stability, product quality, and plant safety. Chlorine (Cl₂) is a highly corrosive and toxic gas that requires specialized instrumentation to manage both accuracy and durability.

This case study highlights how the MTL20FD High Accuracy Mass Flow Controller was applied in a chlorine plant, providing accurate measurement in grams per hour (g/h) and enabling closed-loop control to optimize dosing and minimize risks.

Application:

Accurate measurement and control of chlorine gas flow in grams per hour (G/h) for industrial processes.

Requirements:

- High accuracy (±0.5% or as specified)

- Flow display in grams per hour (G/h)

Customer Challenges

The chlorine plant faced several operational challenges:

- Stable dosing required: Chlorine flow must be precisely controlled for chemical reactions to avoid overdosing or underdosing.

- Corrosion resistance: Standard flow meters failed quickly due to chlorine’s oxidizing nature.

- Process integration: The customer needed a device with 4–20 mA control signal for automatic regulation via DCS.

- Direct mass unit (g/h): Operators required g/h display for simplified process monitoring and reporting.

- Durability and safety: Equipment needed to perform reliably under 2–3 bar pressure without frequent maintenance.

Metlan’s Solution: MTL20FD High Accuracy Mass Flow Controller

The MTL20FD was selected as it provides both measurement and active control of chlorine gas flow. Unlike conventional flow meters, this model integrates a control valve and supports closed-loop PID control, making it suitable for high-precision gas dosing.

Key Technical Configuration

- Medium: Chlorine gas (Cl₂)

- Flow rate: 200 g/h

- Accuracy: ±0.5%

- Display: Digital display, direct g/h readout

- Sensor: PTFE-type for chemical resistance

- Seal: FFKM (perfluoroether rubber) for long-term sealing in corrosive service

- Maximum Pressure: 3Mpa

- Connections: Ferrule type, ID 10 mm

- Control signal: 4–20 mA for DCS integration

- Power supply: 24 V DC

Benefits of Chlorine Flow Control with MTL20FD

- High accuracy measurement: ±0.5% precision ensures exact chlorine dosing, critical in chlor-alkali processes and disinfection.

- Active flow control: Integrated valve and PID algorithm allow the controller to automatically adjust flow, maintaining setpoints even under pressure fluctuations.

- Safety improvement: Stable control reduces chlorine leakage risks caused by overdosing, improving plant safety.

- Direct mass flow in g/h: Enables operators to directly monitor chlorine consumption and dosing in real units, avoiding conversion errors.

- Corrosion resistance: PTFE sensor and FFKM seals extend service life in chlorine gas service.

- System compatibility: Standard 4–20 mA I/O and ferrule fittings simplify installation and integration into the plant’s automation system.

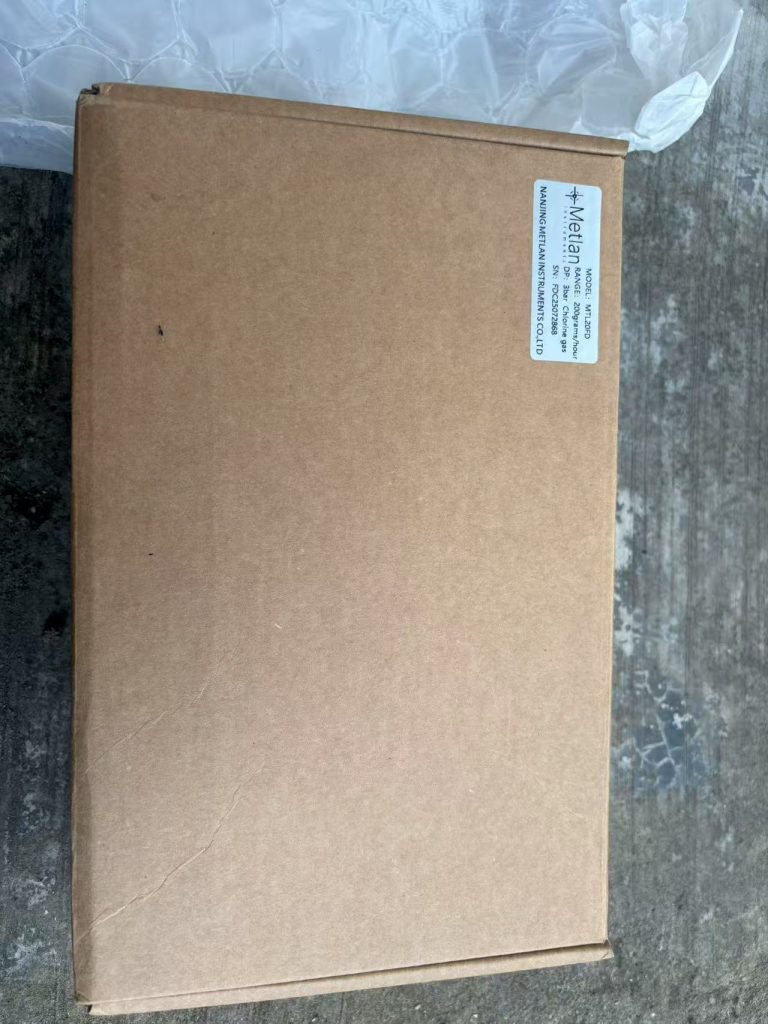

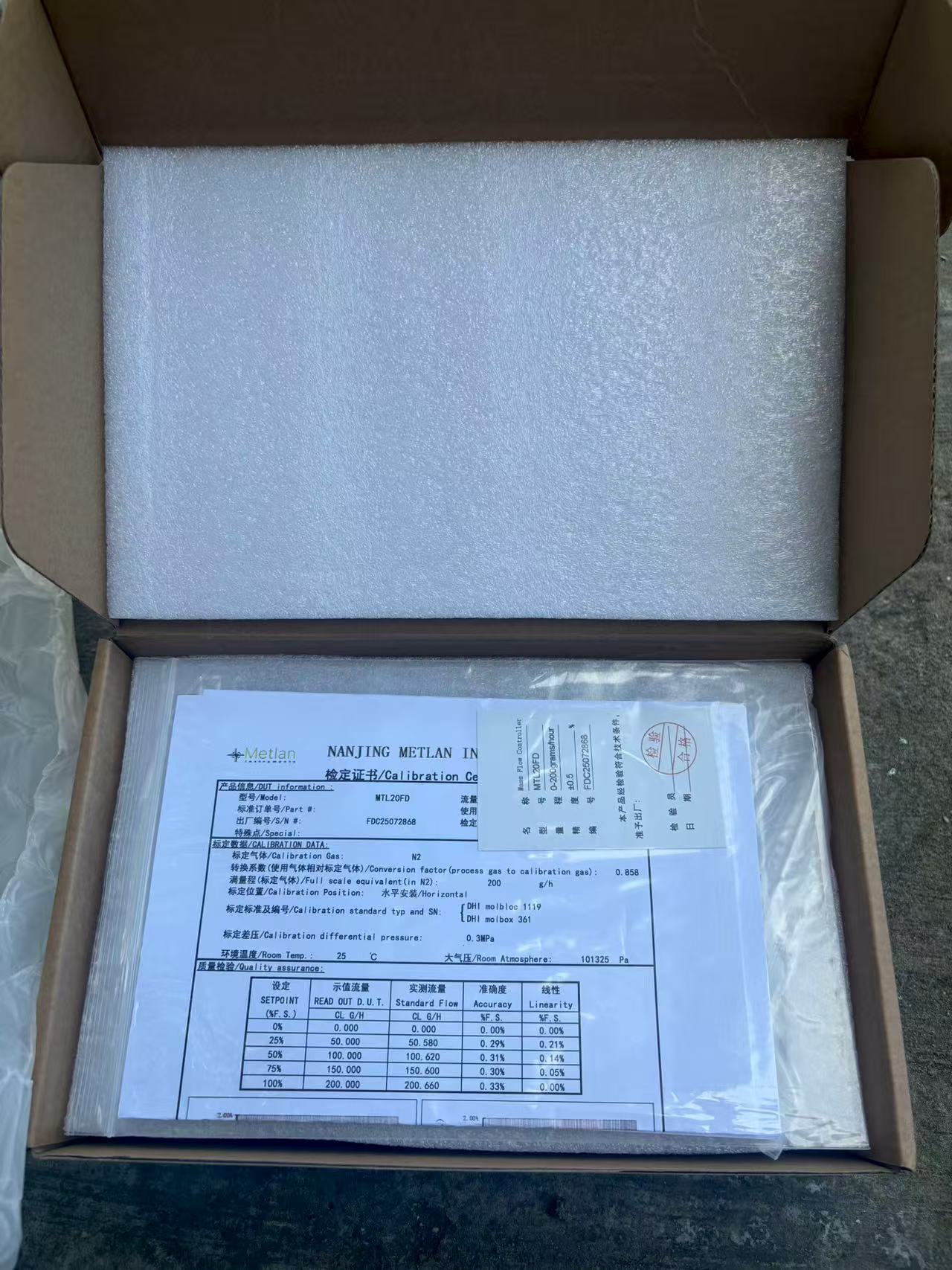

Calibration and Shipping Assurance

Every MTL20FD is factory-calibrated before delivery. The chlorine gas controller undergoes:

- Calibration on precision gas standards to ensure ±0.5% accuracy,

- Leak testing with FFKM seals, ensuring reliable sealing under corrosive gas,

- Final inspection and packaging for safe shipment.

Below are the photos:

Conclusion:

The MTL20FD High Accuracy Mass Flow Controller delivers precise measurement and control of chlorine gas (±0.5%), ensuring accurate dosing, reliable operation, and enhanced process safety.

Need Help With Your Flow Measurement?

If you’re facing challenges with unstable or inaccurate flow readings, contact Metlan Instruments today. Our team is ready to help you find the most reliable and cost-effective solution for your application.