In industries where precision and reliability are non-negotiable—such as semiconductor manufacturing, pharmaceuticals, and chemical processing—gas mass flow controllers (MFCs) are indispensable tools. These devices not only measure the flow rate of gases (especially low flow flow measurement) but also actively regulate it to maintain precise, user-defined setpoints. From ensuring the perfect gas mixture in a reactor to controlling the deposition of thin films on silicon wafers, MFCs play a critical role in optimizing efficiency, safety, and product quality.

Table des matières

Ce guide complet explore en détail les régulateurs de débit massique de gaz, en abordant leurs principes de fonctionnement, leurs types, leurs applications et les éléments clés à prendre en compte lors de la sélection. À la fin, vous comprendrez pourquoi ces dispositifs sont essentiels aux processus industriels modernes et comment choisir celui qui convient à vos besoins.

Qu'est-ce qu'un contrôleur de débit massique de gaz ?

A gas mass flow controller (MFC) est un dispositif qui mesure et réglemente le débit massique d'un gaz en temps réel. Contrairement aux débitmètres volumétriques, qui mesurent le volume (par exemple, en litres par minute), les MFC mesurent le débit massique (par exemple, en centimètres cubes standard par minute, SCCM), en tenant compte des variations de température et de pression. Cela garantit des performances constantes, même dans des environnements dynamiques.

Composants clés:

- Capteur de débit: Measures the gas flow rate (thermal, differential pressure, or Coriolis-based).

- Valve de contrôle: Ajuste le débit en fonction du point de consigne souhaité (par exemple, électrovanne ou vanne piézoélectrique).

- Système de contrôle en boucle fermée: Utilise le retour d'information du capteur pour moduler la position de la vanne.

- Électronique: Traduit les données des capteurs en signaux de commande et fournit des interfaces utilisateur (affichages numériques, sorties analogiques, etc.).

Comment fonctionne un contrôleur de débit massique de gaz ?

Le fonctionnement d'un MFC s'articule autour de trois étapes essentielles : mesure, comparaisonet ajustement.

Étape 1 : Mesure

Le capteur de débit détecte le débit de gaz. Les principes de mesure les plus courants sont les suivants

- Dispersion thermique: Un élément chauffé se refroidit lorsque le gaz passe devant lui ; le changement de température est en corrélation avec le débit massique.

- Pression différentielle (DP): Mesure la chute de pression à travers un élément d'écoulement laminaire ou une plaque d'orifice.

- Effet de Coriolis: Utilise des tubes vibrants pour détecter le débit massique par l'intermédiaire des forces d'inertie.

Étape 2 : Comparaison

Le contrôleur compare le débit mesuré au point de consigne défini par l'utilisateur.

Étape 3 : Ajustement

En cas d'écart, le système de contrôle ajuste l'ouverture de la vanne (via des algorithmes PID) pour augmenter ou réduire le débit jusqu'à ce que le point de consigne soit atteint.

Exemple: Dans un four à semi-conducteurs, une MFC maintient un débit d'argon précis pour créer une atmosphère inerte. Si la pression fluctue, la vanne s'ajuste instantanément pour stabiliser le débit.

Types de régulateurs de débit massique de gaz

Différentes technologies conviennent à différentes applications. Voici les types les plus courants :

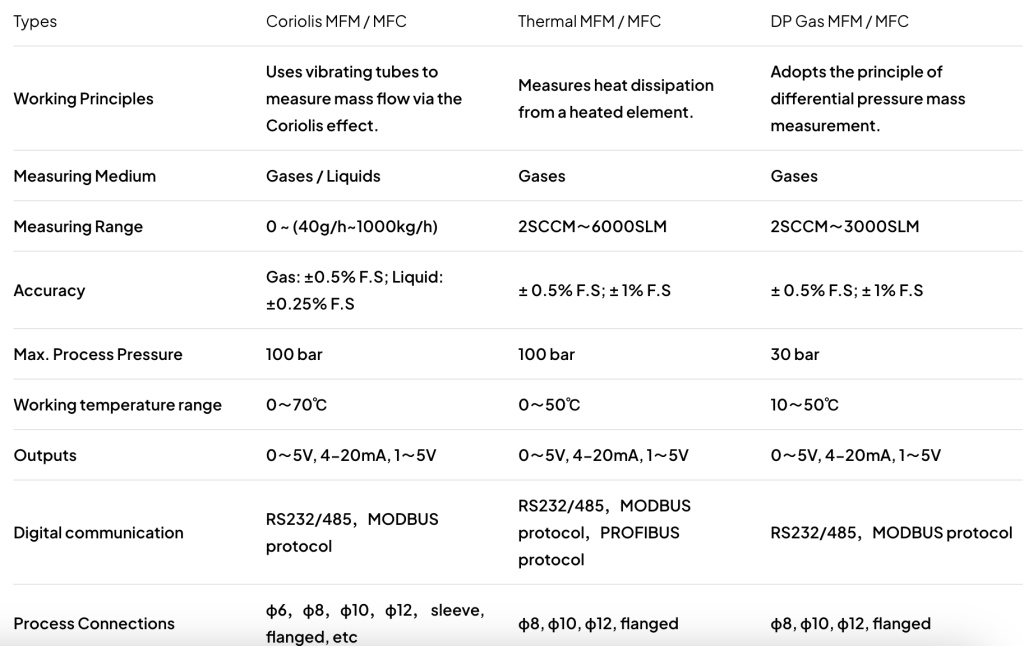

1. Thermal Mass Flow Controllers

Principe: Mesure le transfert de chaleur d'un élément chauffé au gaz.

Caractéristiques :

- Conçu pour la mesure de gaz à faible débit.

- Rapport de réduction : 50:1 pour le régulateur de débit massique numérique ; 100:1 pour le débitmètre massique numérique.

- Temps de réponse : régulateur de débit massique<0,2s ; débitmètre massique <0,1s

- Contrôleur PID intégré pour réguler le débit

- Mesure directe du débit massique, compensation automatique de la température

- Écran tactile

- Convient à diverses canalisations à haute et basse pression.

2. Régulateurs de débit massique à pression différentielle (DP)

Principe: Mesure la chute de pression à travers un élément d'écoulement laminaire.

Caractéristiques :

- Conçu pour la mesure de gaz à faible débit.

- Rapport de réduction : 50:1 pour le régulateur de débit massique numérique ; 100:1 pour le débitmètre massique numérique.

- Temps de réponse : régulateur de débit massique<0,2s ; débitmètre massique <0,1s

- Contrôleur PID intégré pour réguler le débit

- Mesure directe du débit massique, compensation automatique de la température

- Écran tactile

- Pas de préchauffage nécessaire, pas de décalage de réponse pendant la mesure.

3. Régulateurs de débit massique Coriolis

Principe: Mesure le débit massique par l'effet de Coriolis dans des tubes vibrants.

Caractéristiques :

- Conçu pour la mesure de gaz/liquides à faible débit.

- Haute précision, bonne répétabilité. Pour les liquides, la précision de mesure peut atteindre ± 0,25% ; pour les gaz, la précision de mesure peut atteindre ± 0,5%.

- Fiabilité et stabilité élevées, capables de résister à des conditions environnementales extrêmes : Le produit conserve des performances constantes même dans des environnements sujets aux vibrations. En cas de perturbations physiques accidentelles telles que des chocs ou des collisions, le système rétablit automatiquement des mesures stables en 400 millisecondes.

- Il peut mesurer des fluides à haute viscosité et des gaz à haute densité : Le MTL20FE mesure une large gamme de fluides, tels que

L'huile lubrifiante, l'azote liquide et d'autres fluides à haute densité peuvent également être mesurés avec précision.

Tableau de comparaison : Types de MFC à gaz

Applications des régulateurs de débit massique de gaz

Les MFC pour gaz sont essentiels dans les industries qui exigent une distribution précise du gaz. Les principales applications sont les suivantes

1. Fabrication de semi-conducteurs

- Dépôt chimique en phase vapeur (CVD): Contrôle les gaz précurseurs (par exemple, le silane) pour déposer des couches minces sur des plaquettes.

- Gravure au plasma: Régule les gaz réactifs (par exemple, CF₄) pour graver les microstructures.

2. Production pharmaceutique

- Contrôle de l'alimentation du réacteur: Maintains exact gas ratios (e.g., O₂, CO₂ flow meter) in bioreactors.

- Stérilisation: Gère le flux d'oxyde d'éthylène pour la stérilisation des dispositifs médicaux.

3. Surveillance de l'environnement

- Essais d'émissions: Mesure les gaz à effet de serre (par exemple, CO₂, CH₄) dans les émissions de cheminée.

- Systèmes de qualité de l'air: Contrôle les gaz d'étalonnage dans les analyseurs.

4. Recherche sur les piles à combustible et les batteries

- Contrôle du débit d'hydrogène: Optimise la distribution de H₂ dans les piles à combustible PEM.

- Gestion des gaz électrolytiques: Régule l'argon dans la production de batteries lithium-ion.

5. Aérospatiale

- Essais du moteur: Simule les conditions d'altitude en contrôlant les mélanges air/azote.

- Systèmes de survie: Gère l'O₂ et le N₂ dans les cabines des vaisseaux spatiaux.

Comment choisir un régulateur de débit massique de gaz

Pour choisir le bon MFC, il faut évaluer :

- Compatibilité des gaz:

- Les gaz corrosifs (par exemple, HCl) nécessitent une construction en acier inoxydable ou en Hastellay®.

- Les applications sensibles à l'humidité nécessitent des filtres déshydratants.

- Plage de débit:

- Assurez-vous que le MFC couvre vos débits minimum et maximum (par exemple, 0-500 SCCM).

- Exigences de précision:

- Les processus de haute précision (par exemple, la fabrication de semi-conducteurs) nécessitent des MFC Coriolis ou thermiques.

- Protocoles de communication:

- Choisissez des interfaces analogiques (4-20 mA), numériques (Modbus, Profibus) ou de bus de terrain (EtherCAT).

- Certifications:

- Les environnements dangereux (ATEX, IECEx) exigent des conceptions antidéflagrantes.

Les contrôleurs de débit massique de gaz sont les héros méconnus des processus industriels modernes, permettant une précision inégalée dans les industries où chaque molécule compte. Que vous fabriquiez des dispositifs semi-conducteurs à l'échelle nanométrique ou que vous développiez des produits pharmaceutiques vitaux, le choix du bon MFC - thermique, DP, Coriolis ou autre - garantit l'efficacité, la conformité et la qualité du produit.