In chlorine production and chemical processing, precise chlorine gas flow measurement and control is essential for process stability, product quality, and plant safety. Chlorine (Cl₂) is a highly corrosive and toxic gas that requires specialized instrumentation to manage both accuracy and durability.

This case study highlights how the MTL20FD High Accuracy Mass Flow Controller was applied in a chlorine plant, providing accurate measurement in grams per hour (g/h) and enabling closed-loop control to optimize dosing and minimize risks.

Application :

Accurate measurement and control of chlorine gas flow in grams per hour (G/h) for industrial processes.

Exigences :

- High accuracy (±0.5% or as specified)

- Flow display in grams per hour (G/h)

Customer Challenges

The chlorine plant faced several operational challenges:

- Stable dosing required: Chlorine flow must be precisely controlled for chemical reactions to avoid overdosing or underdosing.

- Corrosion resistance: Standard flow meters failed quickly due to chlorine’s oxidizing nature.

- Process integration: The customer needed a device with 4–20 mA control signal for automatic regulation via DCS.

- Direct mass unit (g/h): Operators required g/h display for simplified process monitoring and reporting.

- Durability and safety: Equipment needed to perform reliably under 2–3 bar pressure without frequent maintenance.

Metlan’s Solution: MTL20FD High Accuracy Mass Flow Controller

Le MTL20FD was selected as it provides both measurement and active control of chlorine gas flow. Unlike conventional flow meters, this model integrates a control valve and supports closed-loop PID control, making it suitable for high-precision gas dosing.

Key Technical Configuration

- Medium: Chlorine gas (Cl₂)

- Flow rate: 200 g/h

- Précision : ±0,5%

- Display: Digital display, direct g/h readout

- Sensor: PTFE-type for chemical resistance

- Seal: FFKM (perfluoroether rubber) for long-term sealing in corrosive service

- Maximum Pressure: 3Mpa

- Connections: Ferrule type, ID 10 mm

- Control signal: 4–20 mA for DCS integration

- Power supply: 24 V DC

Benefits of Chlorine Flow Control with MTL20FD

- High accuracy measurement: ±0.5% precision ensures exact chlorine dosing, critical in chlor-alkali processes and disinfection.

- Active flow control: Integrated valve and PID algorithm allow the controller to automatically adjust flow, maintaining setpoints even under pressure fluctuations.

- Safety improvement: Stable control reduces chlorine leakage risks caused by overdosing, improving plant safety.

- Direct mass flow in g/h: Enables operators to directly monitor chlorine consumption and dosing in real units, avoiding conversion errors.

- Corrosion resistance: PTFE sensor and FFKM seals extend service life in chlorine gas service.

- System compatibility: Standard 4–20 mA I/O and ferrule fittings simplify installation and integration into the plant’s automation system.

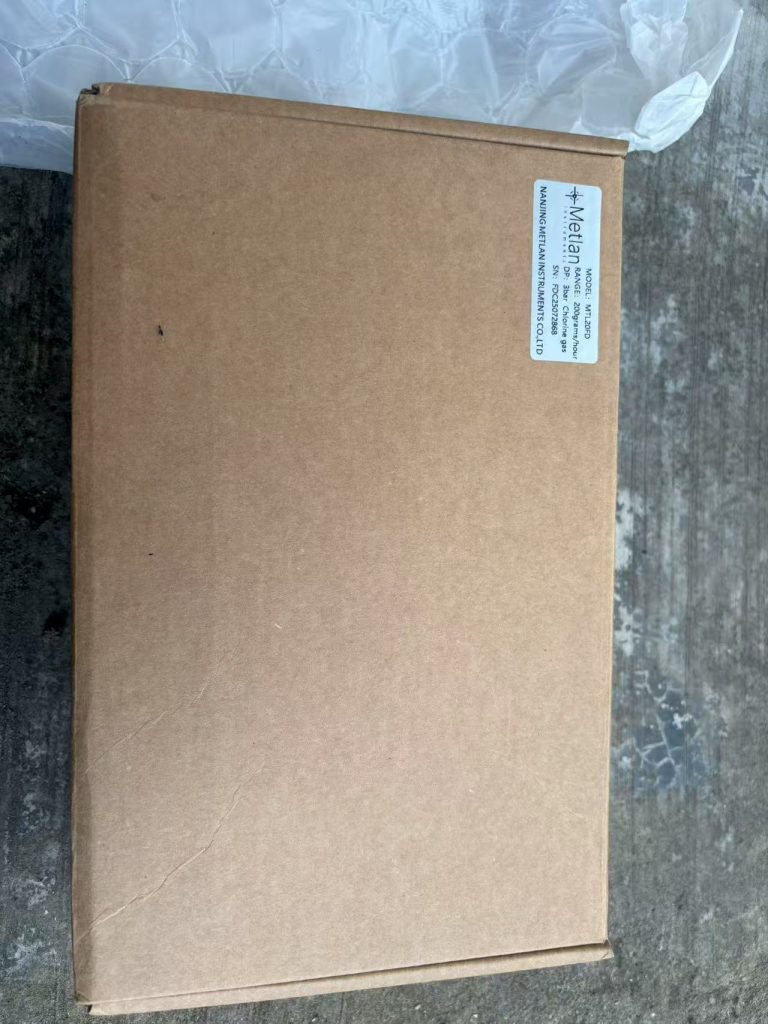

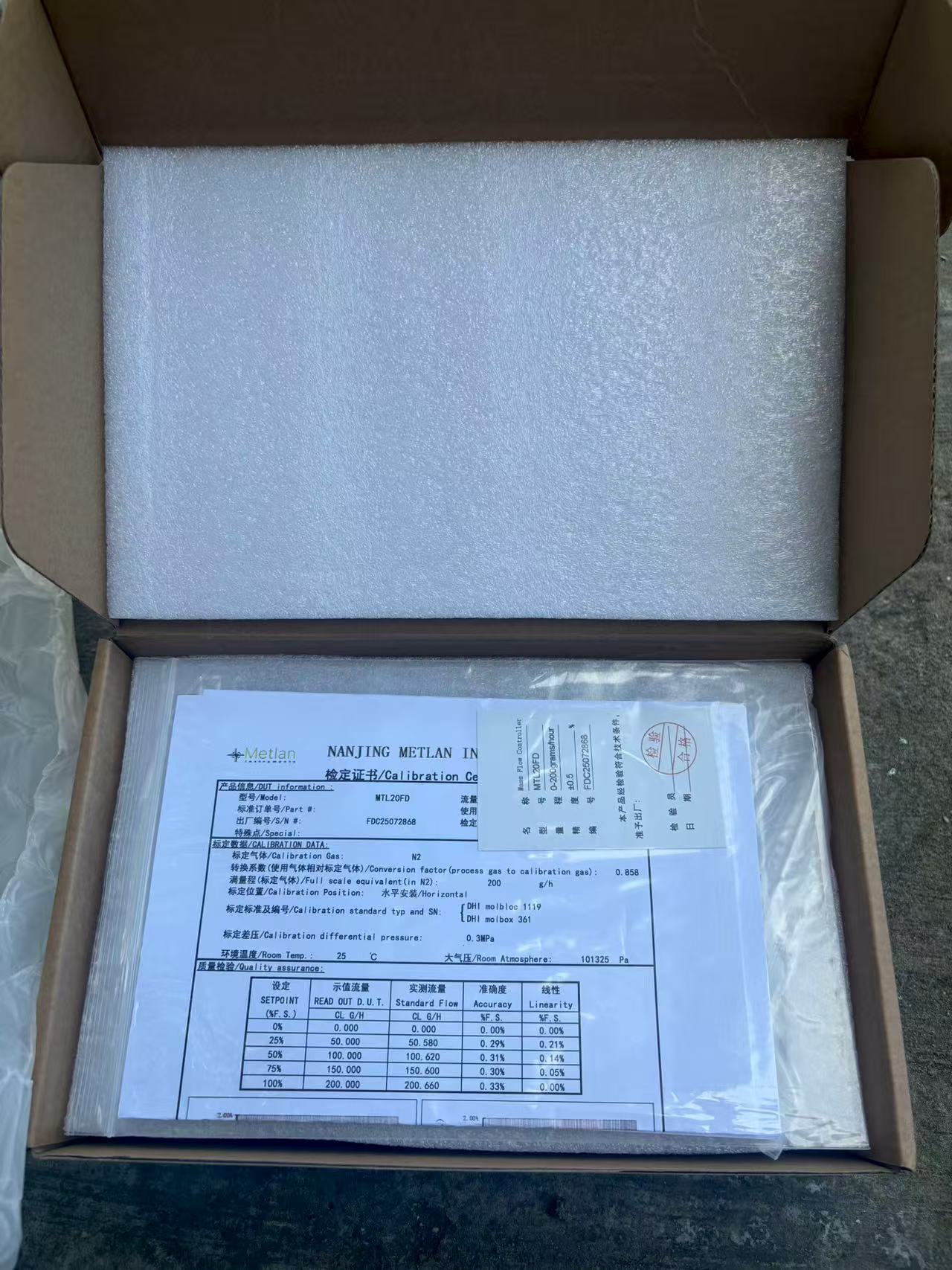

Calibration and Shipping Assurance

Every MTL20FD is factory-calibrated before delivery. The chlorine gas controller undergoes:

- Calibration on precision gas standards to ensure ±0.5% accuracy,

- Leak testing with FFKM seals, ensuring reliable sealing under corrosive gas,

- Final inspection and packaging for safe shipment.

Below are the photos:

Conclusion :

Le MTL20FD High Accuracy Mass Flow Controller delivers precise measurement and control of chlorine gas (±0.5%), ensuring accurate dosing, reliable operation, and enhanced process safety.

Besoin d'aide pour la mesure du débit ?

If you’re facing challenges with unstable or inaccurate flow readings, contact Metlan Instruments today. Our team is ready to help you find the most reliable and cost-effective solution for your application.