Turndown ratio—sometimes called “rangeability”—is one of the most important yet frequently overlooked parameters when selecting a flow meter. Although engineers often focus on accuracy, pressure rating, or compatibility, the turndown ratio determines whether a flow meter can reliably measure flow across the full range of operating conditions. A misunderstanding of this parameter can lead to poor measurement accuracy, unstable readings, or even complete system failure.

Table des matières

What Is Turndown Ratio?

Turndown ratio is the ratio of the maximum measurable débit to the minimum measurable flow rate of a flow meter while maintaining its specified accuracy.

Formula

Turndown Ratio = Qmax / Qmin

Où ?

- Qmax = highest flow rate where accuracy is maintained

- Qmin = lowest flow rate where accuracy is maintained

Example:

If a flow meter measures accurately from 2 L/min to 100 L/min:

Turndown = 100 / 2 = 50:1

This means the same meter can measure across a 50-fold range of flow rates without losing accuracy.

Why Turndown Ratio Matters

A higher turndown ratio provides several benefits:

1. Wider Operating Range

A large turndown allows a single meter to handle normal operating flow, startup flow, low-flow maintenance states, and high-flow peak conditions.

2. Better Low-Flow Performance

Low flow is where many flow meters fail; a high turndown ensures stable, accurate signals even at low velocities.

3. Fewer Flow Meters Needed

A single meter may replace multiple ranges, reducing capex and installation complexity.

4. Improved Control in Variable Flow Systems

Industries such as chemical dosing, gas delivery, energy systems, and research environments often require stable readings across large dynamic ranges.

5. Cost–Performance Optimization

Higher turndown typically comes with higher price—but drastic improvements in accuracy, safety, and control can justify the investment.

How to Calculate Turndown Ratio Correctly

Engineers must ensure turndown is calculated based on useful measurement range, not merely the physical capability of the meter.

✔ Correct:

Qmin = smallest flow that meets the stated accuracy

✘ Incorrect:

- Minimum detectable flow

- Minimum displayed flow

- Zero-point drift range

A meter that can “detect” flow at low velocity is not necessarily “accurate” at that velocity.

Only flows that meet specifications (± accuracy % and repeatability) should be counted.

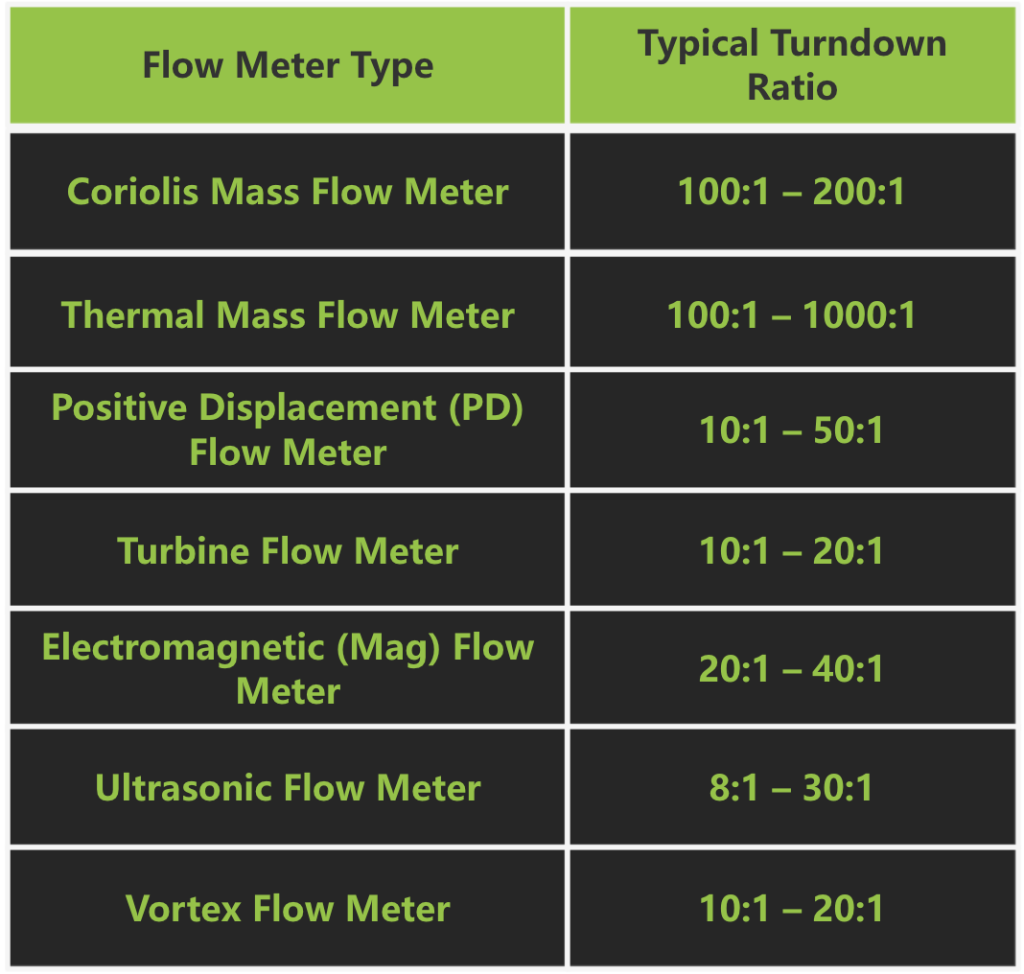

Typical Turndown Ratios for Different Flow Meter Technologies

Every measurement technology has its own inherent rangeability limits. Below is a comprehensive comparison.

Débitmètre massique Coriolis

Typical Turndown: 100:1 to 200:1

Why so high?

- Direct débit massique mesure

- Excellent signal-to-noise ratio

- Not dependent on velocity profile or Reynolds number

- Suitable for high viscosity or density-changing fluids

Ideal for: High-accuracy chemical dosing, gas measurement, oil & fuel, hydrogen, chlorine, and corrosive gases.

Débitmètre massique thermique

Typical Turndown: 100:1 to 1000:1, Metlan Instruments has 2500:1

Strengths:

- Ultra-sensitive to small flow changes

- Excellent for clean gases

- Direct mass flow output

Ideal for: Air, nitrogen, natural gas, hydrogen, specialty gases

Positive Displacement (PD) Flow Meter

Typical Turndown: 10:1 to 50:

Strengths:

- Excellent accuracy for viscous liquids

- Not affected by flow profile or Reynolds number

Ideal for: Hydraulic oil, fuel oil, lubrication oil, additives, high-viscosity fluids.

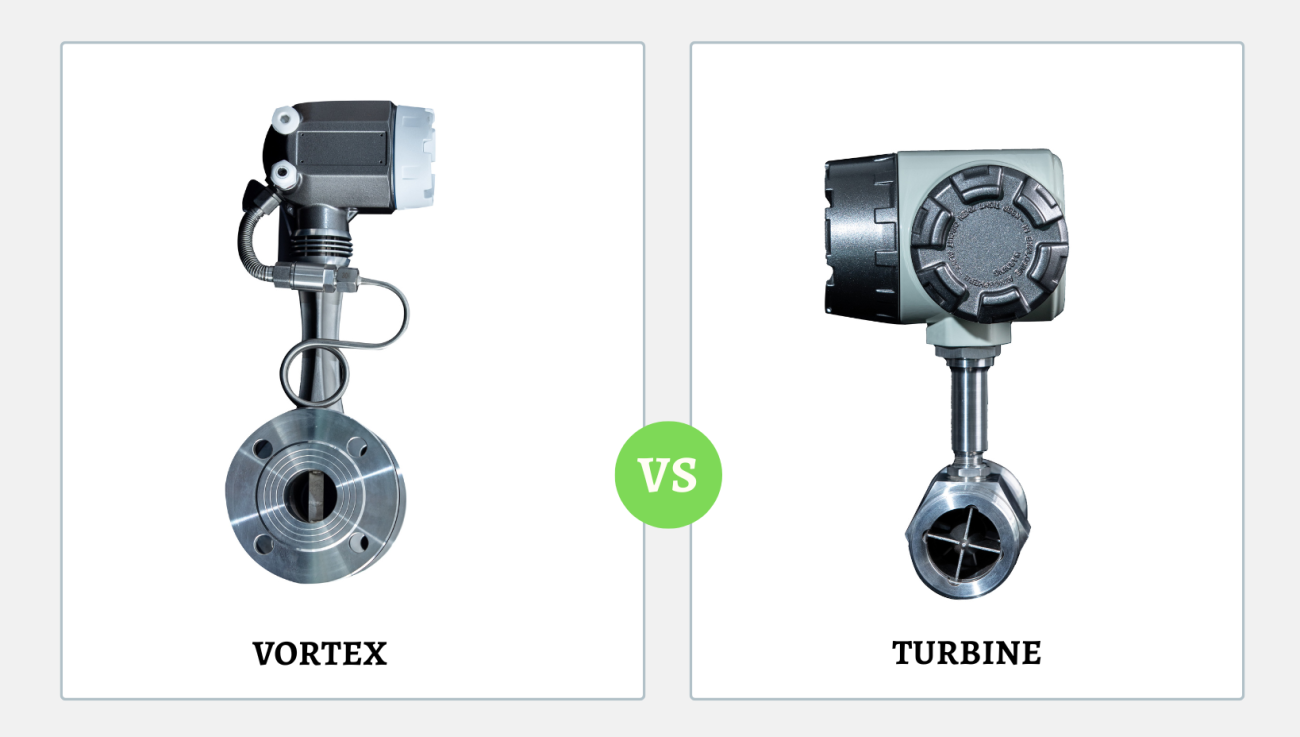

Débitmètre à turbine

Typical Turndown: 10:1 to 20:1

Strengths:

- Good for clean, low-viscosity fluids

- High accuracy at medium flow velocities

Ideal for: Essence, kerosene, clean gases, water

Electromagnetic (Mag) Flow Meter

Ultrasonic Flow Meter

Typical Turndown:

- Inline type: 10:1 to 30:1

- Clamp-on type: 8:1 to 20:1

Ideal for: Large pipes, water networks, non-intrusive monitoring.

Débitmètre à vortex

Typical Turndown: 10:1 to 20:1, Metlan reaches 53:1

Strengths:

- Reliable for steam and clean gases

- Good temperature & pressure tolerance

Ideal for: Vapeur, compressed air, natural gas, industrial gases.

How Turndown Ratio Influences Performance and Selection

Turndown ratio impacts almost every aspect of flow meter behavior.

1. Accuracy & Repeatability

High turndown means the meter maintains accuracy across a wide dynamic range.

Low turndown means accuracy drops rapidly when flow deviates from the “sweet spot.”

2. Stability & Signal Quality

Even if you use only a part of the meter’s range, a higher turndown ratio still means stronger performance and better stability.

Why?

Because meters with higher turndown capability generally use:

- More sensitive sensors

- Better signal processing

- Higher-quality construction

That means even your day-to-day operating range benefits from lower noise and more consistent readings.

3. Meter Selection Flexibility

A meter with a large turndown allows:

- Multi-condition operations

- Startup, purge, idle, peak flow all within one meter

- Less oversizing or undersizing

- Ability to adapt to future system changes

4. Cost

Higher turndown ratio typically means higher price due to:

- More advanced sensors

- Better signal processing

- Higher-grade materials

- Tighter manufacturing tolerances

5. Impact on Process Control

In real-time control loops (valves, PLC, dosing systems):

- Low turndown meters cause oscillation or instability

- High turndown meters provide smooth, stable readings

This is critical in:

- Chlorine dosing

- Hydrogen delivery

- Fuel injection

- Steam control

- Chemical batching